215

TROUBLESHOOTING

24) Inspect Engine Coolant Pump

2. Check connector condition

1) Check the connectors on the DCBL PCB for disconnection or connection failure.

2) Check the relay connectors between the DCBL PCB and engine coolant pump for disconnection or connection

failure.

3. Check DCBL PCB body

1) Check input voltage to the DCBL PCB

(1) Check that approximately 15 V DC of power supply voltage is applied at CN1[1]-[2] on the DCBL PCB.

(2) Check that approximately 200 V AC of power supply voltage is applied at CN5[1]-[2] on the DCBL PCB.

2) Check output voltage from the DCBL PCB

(1) Select "Engine coolant refilling (code No. 0A)" in the check mode of the board maintenance functions.

Then turn the engine coolant pump ON.

(2) Check that approximately 160 V AC of engine coolant pump power supply voltage is applied at CN9[1]-[2],

[1]-[3], and [2]-[3] on the DCBL PCB.

(3) Check that approximately 280 V DC of power supply voltage is applied at CN4[1]-[3] on the DCBL PCB.

When refilling engine coolant, be sure to use AISIN Coolant S.

When refilling engine coolant, be sure to mix with the following balance 50 ~ 60 vol%

(engine coolant: 0.55, water: 0.45).

Amount of engine coolant

8 TON 3.96 gal (15 L)

15 TON 6.87 gal (26 L)

1. Inspect engine coolant pump unit

[Check during operation]

1) Select "Engine coolant refilling (code No. 0A)" in

the check mode of the board maintenance func-

tions. Then turn the engine coolant pump ON.

2) Check the engine coolant pump for abnormal

noise.

3) Check the engine coolant pump for abnormal

vibration.

4) Check the engine coolant circuit for air intrusion.

5) Check that the engine coolant level in the reserve

tank is not lower than reference line.

6) Check around the reserve tank for the evidence

of engine coolant spout.

[Check during system stop]

Turn OFF the electric leakage breaker and check

the motor coil resistance value of the engine cool-

ant pump.

Standard resistance value

8 TON 16 ~ 25 Ω

15 TON 10 ~ 18 Ω

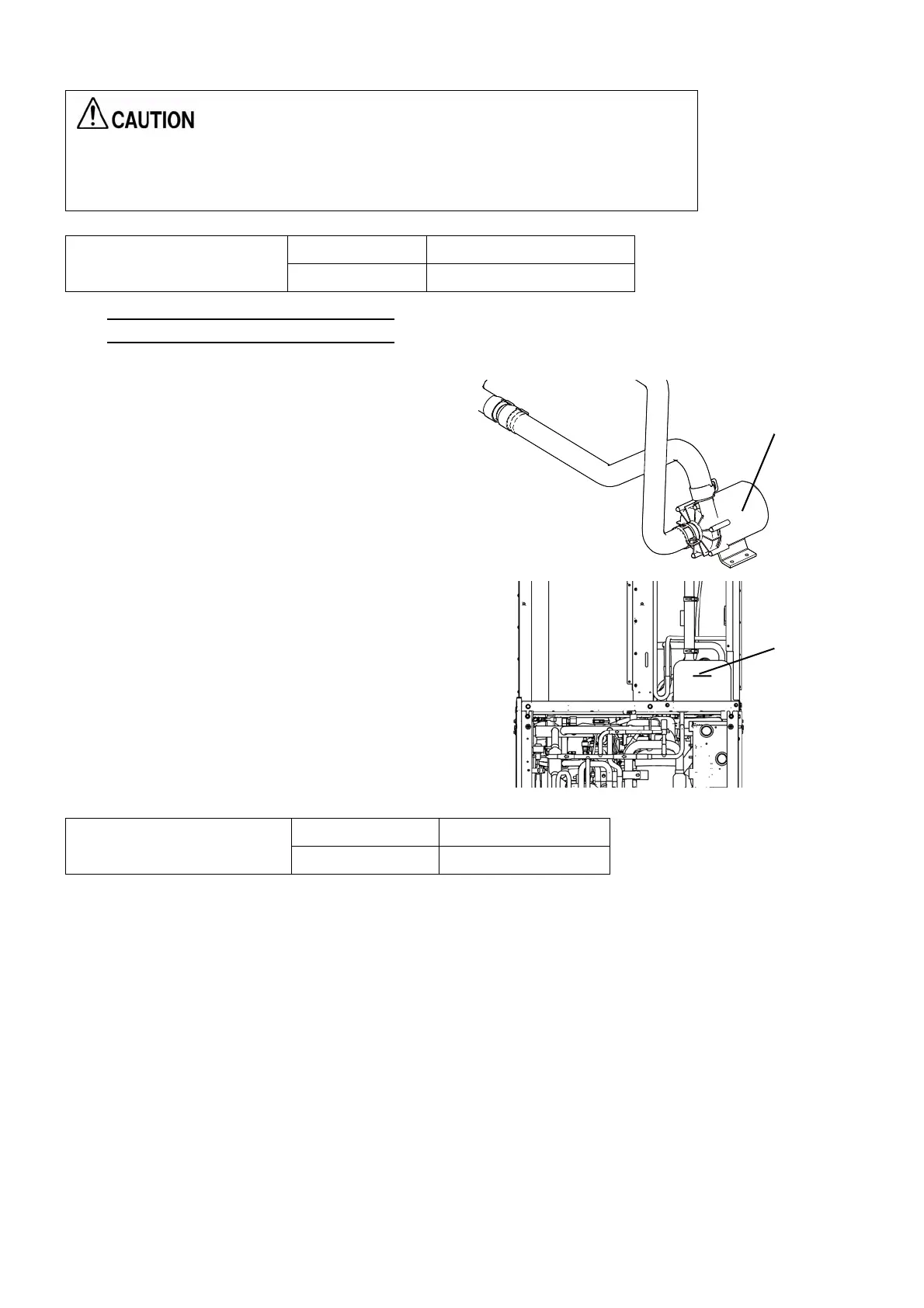

Engine coolant pump

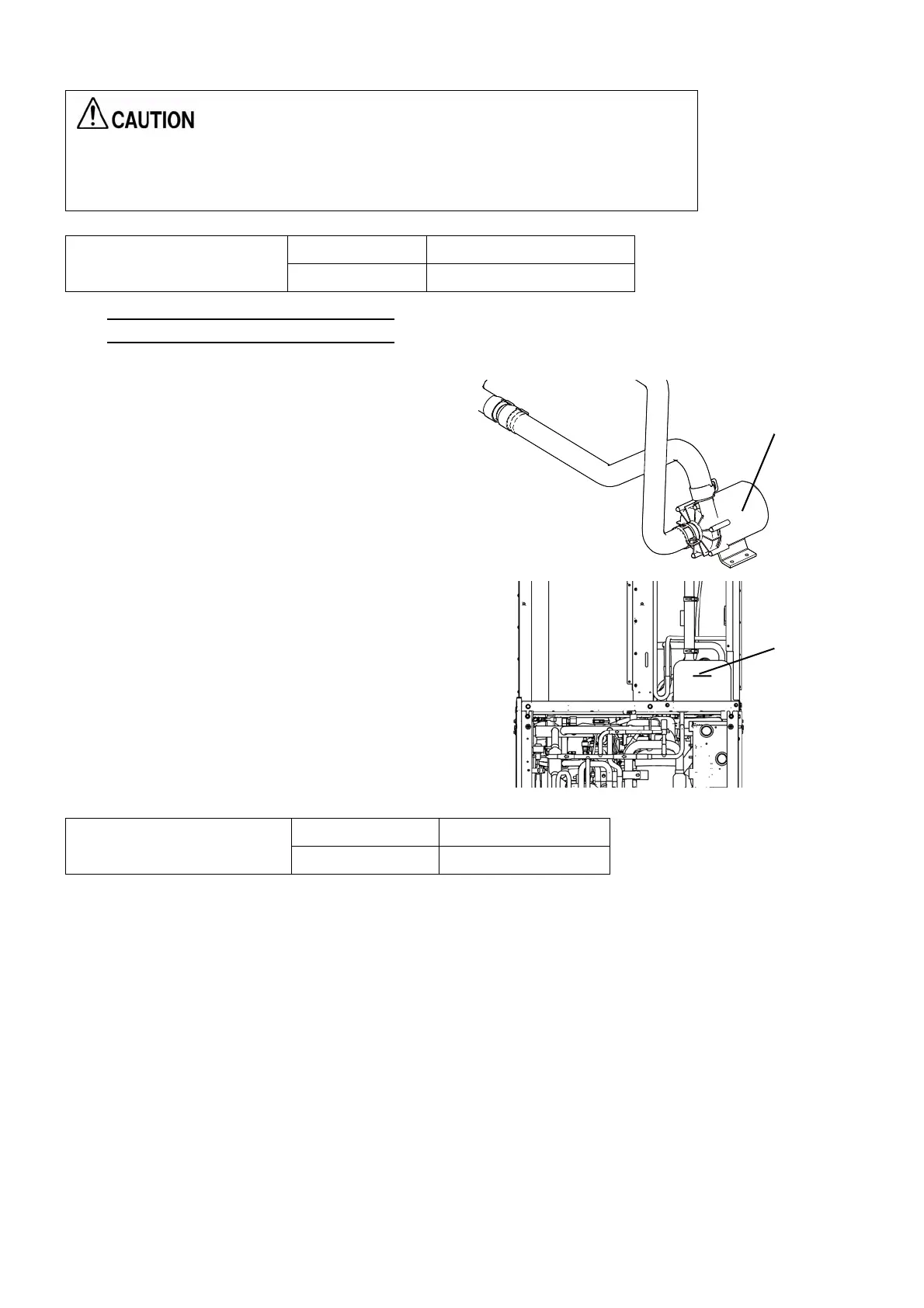

Reference line

Loading...

Loading...