57

PERIODIC INSPECTION

11. Install the cylinder head cover and spark plugs with the reverse procedure for the removal.

NOTE)

Do not use a feeler gauge with a blade thickness of 0.008 inch (0.2 mm) or more. When adjusting a clearance

of 0.008 inch (0.2 mm) or more, use two blades of feeler gauge.

Do not use a feeler gauge with bent or rusty blades.

When adjusting a valve clearance (while warm), set the target in the range from 0.013 inch (0.33 mm) ~ 0.015

inch (0.38 mm) (allows the insertion of a 0.013 inch (0.33 mm) blade but not a 0.015 inch (0.38 mm) blade).

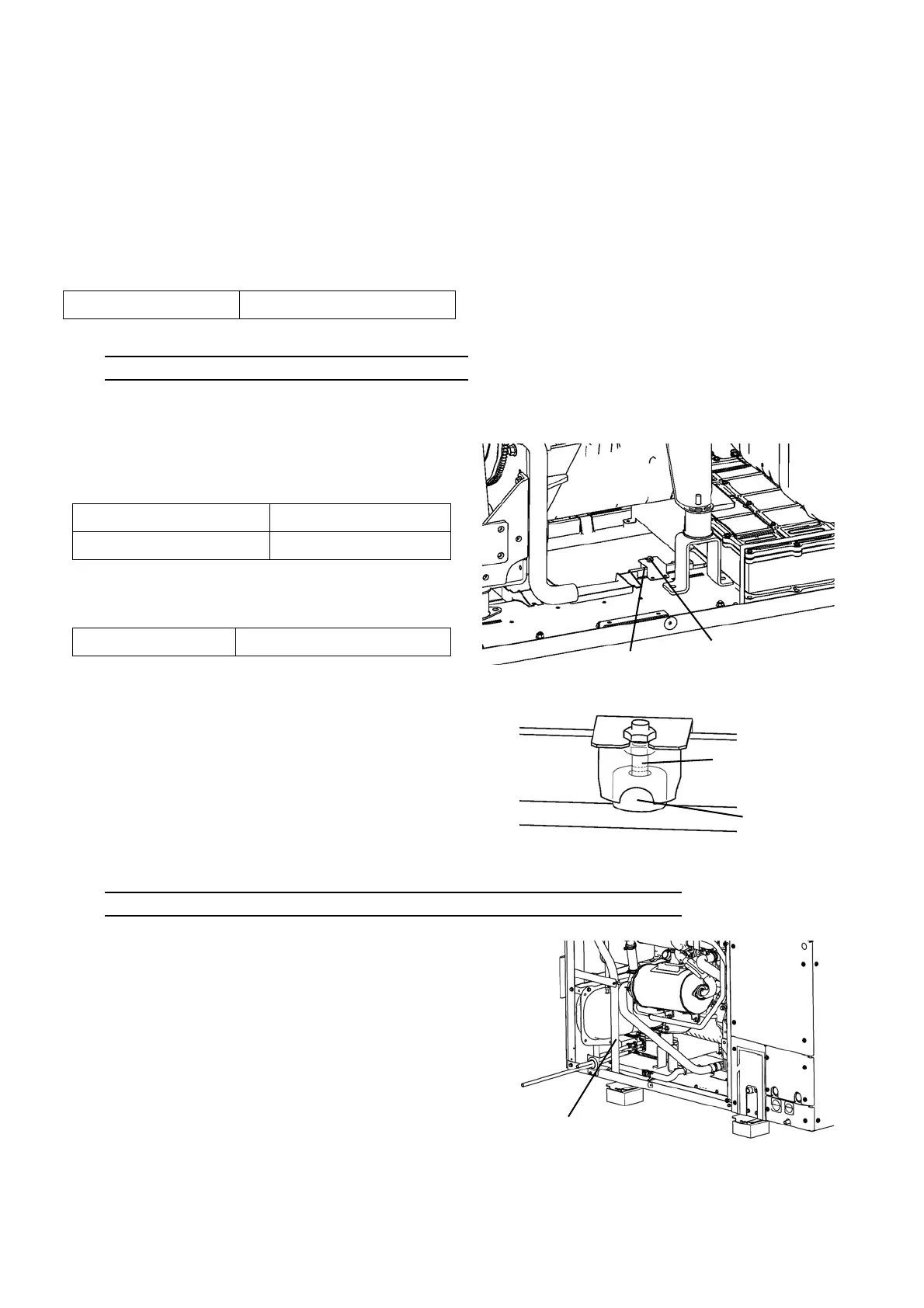

21) Oil Level Switch Cleaning / Inspection

Inspection

1. Check the continuity of the oil level switch by moving

the oil level detecting float up and down with your

finger.

2. Check the shaft for accumulation of foreign object or

damage.

Cleaning

1. Move the oil level detecting float up and down with

your finger, and wipe out the foreign object accumu-

lating on the shaft with rag.

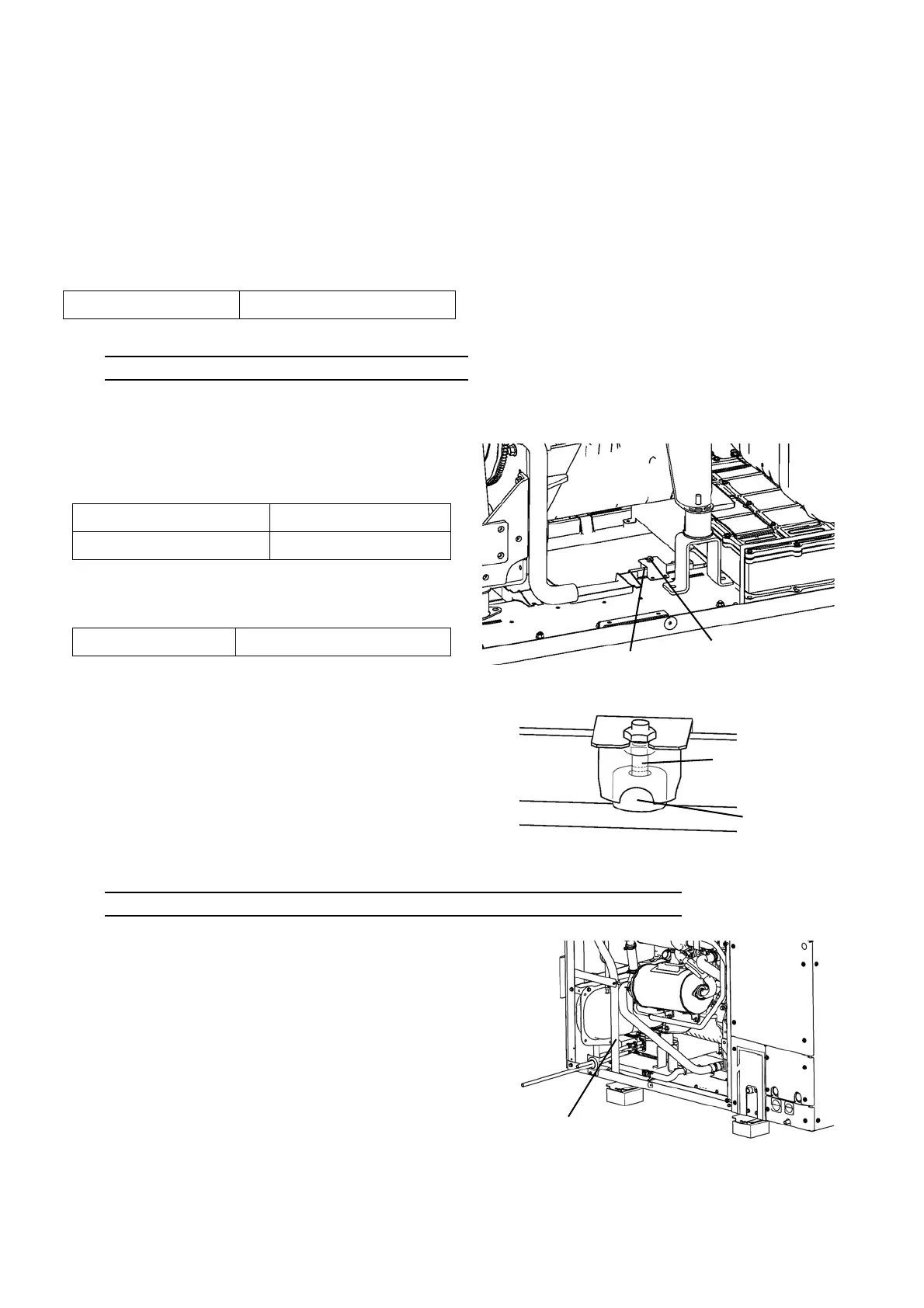

22) Outdoor Heat Exchanger Compartment Drainage Inspection

1. Check if the rainwater in the outdoor heat exchanger

compartment drains to the outside of the unit through

the drain hose.

Adjusting interval Every 3 years (10,000 hours)

Switch

Float

Shaft

Float

When the float is up There is no continuity

When the float is down There is continuity

Inspection interval Every 3 years (10,000 hours)

Drain hose

Loading...

Loading...