134

CONTROL

CONTROL

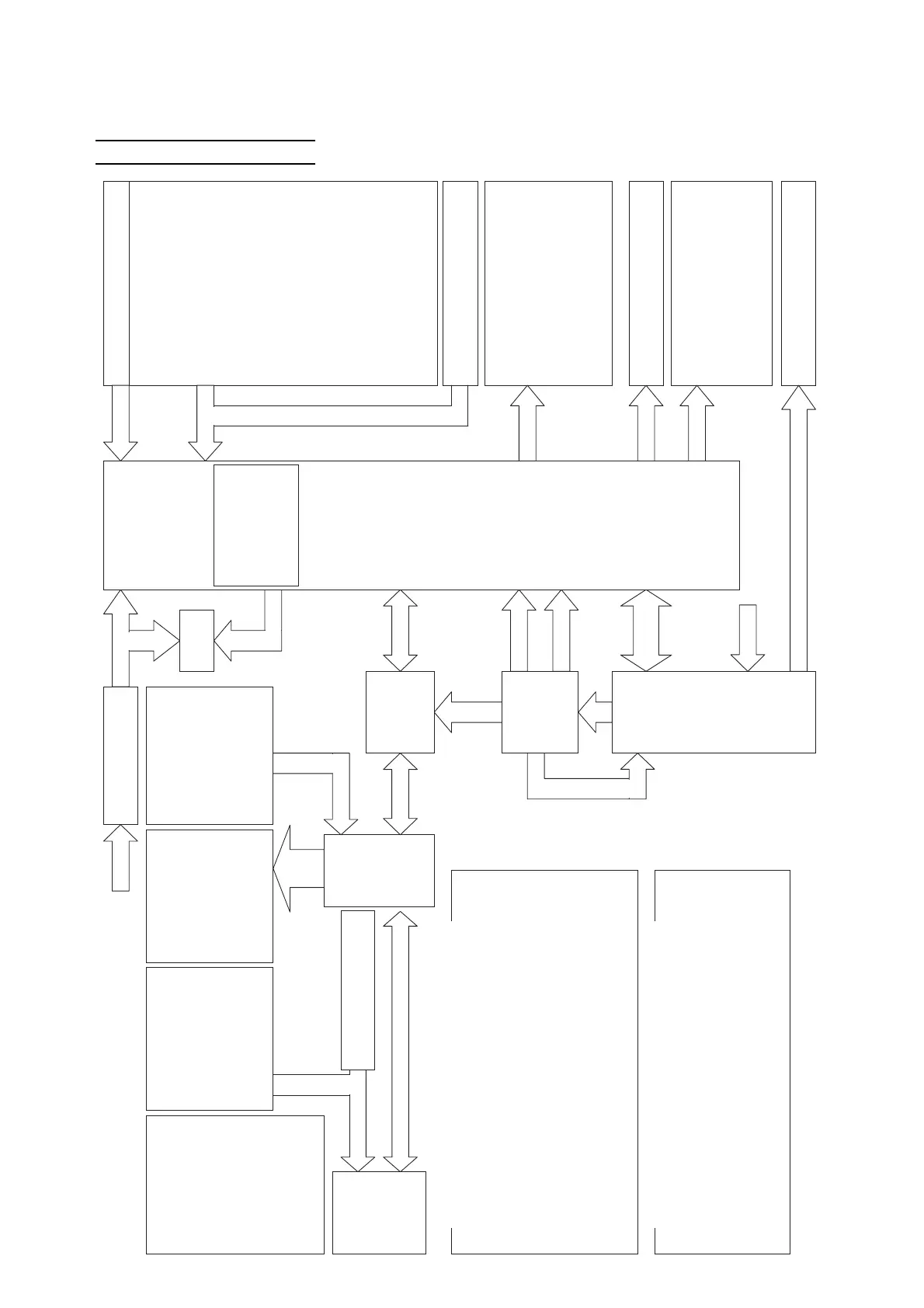

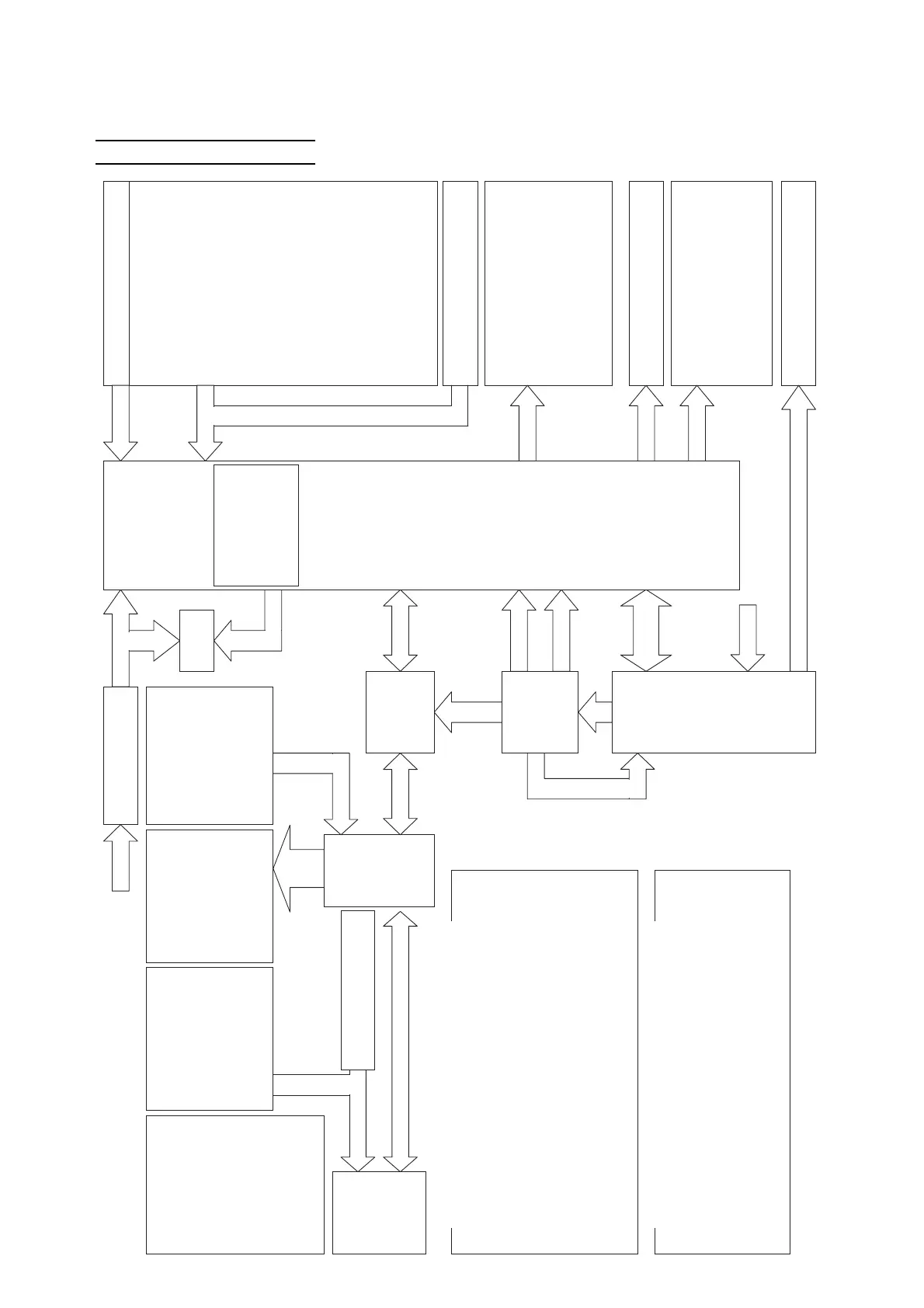

1. System Control Functions

1) System Block Diagram

㩷 1. Under centralized

control

㩷 2. Operation mode

㩷

3. Set air volume

㩷

4. Wind direction

(Fixed/ Swing)

㩷 5. Set temperature

㩷 6. Timer time

㩷

7. Filter sign

㩷 8. Defrosting / Hot start

㩷 9. Error code

10. Operation lamp

11. Inspection / Test

operation display

12. Under master control

㩷 1. Run / Stop

㩷 2. Operation switching

㩷 3. Air volume control

㩷

4. Wind direction control

㩷

5. Temperature control

㩷 6. Timer setting

㩷 7. Timer time

㩷 8. Filter reset

㩷

9. Inspection / Test

operation button

㩷 1. Fan motor

㩷 2. Swing flap

㩷 3. Drain motor

㩷 4. Connector for

external control

adapter

㩷 5. Electronic expansion

valve

㩷 1. Indoor intake air

temperature sensor

㩷 2. Indoor vapor pipe

temperature sensor

㩷 3. Indoor liquid pipe

temperature sensor

㩷 4. Float switch

㩷 5. Limit switch

㩷㩷䋨Swing flap䋩

㩷 6. External input

Indoor unit㩷㸢㩷Remote controller

㩷 1. Run / Stop

㩷 2. Operation mode

㩷㩷㩷(Dehumidifying / Cooling /

Fan / Heating)

㩷 3. Fan air volume

㩷 4. Wind direction

㩷 5. Set temperature

㩷 6. Filter sign

㩷 7. Defrosting / Hot start

㩷 8. Under centralized control

㩷

9. Indoor unit address number

10. Error code

11. Under master control

Remote controller㩷㸢㩷Indoor unit

㩷 1. Run / Stop

㩷 2. Operation mode

㩷㩷㩷(Dehumidifying / Cooling /

Fan / Heating)

㩷 3. Fan air volume

㩷 4. Wind direction

㩷 5. Set temperature

㩷 6. Filter reset

䋨7. Remote controller sensor

temperature䋩

㩷 * When using a remote controller

with the sensor

Remote

controller

㩷 1. Remote controller sensor

㩷 2. Main / Sub selector switch

Input signal

Indoor unit

㩷 1. Refrigerant high pressure switch

㩷 2. Engine oil pressure switch

㩷 3. Engine coolant temperature sensor

㩷 4. Outside air temperature sensor

㩷 5. Compressor discharge pipe

temperature sensor

㩷 6. Compressor intake temperature

sensor

㩷 7. Engine compartment temperature

sensor

㩷 8. Sub heat exchanger liquid

temperature sensor

㩷 9. Outdoor liquid pipe temperature

sensor

10. Heat exchanger liquid temperature

sensor

11. Heat exchanger vapor temperature

sensor

12. Accumulator outlet temperature

sensor

13. Refrigerant high pressure sensor

14. Refrigerant low pressure sensor

15. Engine speed sensor

16. Voltage sensor (starter, igniter)

17. Engine exhaust air temperature

sensor (option only)

18. Oil level switch

With board maintenance function

㩷 1. EEP dip switch

㩷

㩷 1. Throttle valve

㩷 2. Fuel gas flow control valve

㩷 3. Igniter

㩷 4. Outdoor heat exchanger liquid flow

control valve

㩷 5. Sub heat exchanger liquid flow

control valve

㩷 6. Su䌢cooling valve

㩷

㩷

7. Oil bypass control valve

㩷

8. Electromagnetic gas valve

㩷 1. Ignition coil

㩷 2. Compressor clutch

㩷 1. Reversing valve

㩷 2. Hot gas bypass valve

㩷 3. Compressor heater

㩷 4. Electromagnetic compressor capacity

valve

㩷 5. Exhaust water drain heater

(option only)

㩷 6. Engine oil pan heater (option only)

Maintenance devices

Input signal

Setting on

Output (DC 12V)

Power supply

board

Power supply

for control

Ignition system

power supply

Control

signal

DC 280V

DC 12V

DC 12V

㩷 1. Fan motor

㩷 2. Engine coolant pump

PWM out

ut

AC 200V

DCBL board

Display

C200V

Communication

I/F board

Power supply

for control

DC 16V

Communication

Communication

Communication

Power supply

for control

DC 15V

Out

ut

Input signal

AC / DC converter

䋨Transformer, diode䋩

C 200V

DC 12V

Starter

Communication

Drive signal

Output (DC 12V)

Output (AC 200V)

Operation

Communication items between remote controller and indoor unit

Outdoor unit controller

Main board

䊶Running hours display

䋨Board maintenance

function䋩

䊶Error monitor (Red)

Indoor unit㩷㸢㩷Outdoor unit

㩷 1. Run / Stop

㩷 2. Operation mode

㩷㩷㩷(Dehumidifying / Cooling /

Fan / Heating)

㩷 3. Temperature control request

㩷 4. Error code

㩷 5. Intake air / Heat exchanger

temperature

Outdoor unit㩷㸢㩷Indoor unit

㩷 1. Compressor status

㩷 2. Operation mode

㩷 3. Defrosting signal

㩷 4. Error code

Communication items between indoor unit and outdoor unit

Loading...

Loading...