133

REPLACEMENT OF MAIN COMPONENTS

NOTE) When more than one indoor unit is connected, add 2.2 lbs (1 kg) more refrigerant to the above-mentioned

formula.

[When more than one indoor unit is connected]

12. After refilling, run the engine 10 ~ 20 minutes and measure the belt tension again. If the belt tension is out of

standard range, repeat adjust.

※ Measure the belt tension with a sonic belt tension gauge. Tension values for a mechanical belt tension gauge

on the chart are reference values.

13. Check the operating status by measuring high and low pressure and temperature of the refrigerant.

(Refer to P305 and after, [Standard Operation Data] for the standard value)

NOTE) After operation check, check that the service port cap and other parts are securely tightened.

l

1

=Liquid piping Ф7/8 inch total length (ft)

l

2

=Liquid piping Ф3/4 inch total length (ft)

l

3

=Liquid piping Ф5/8 inch total length (ft)

l

4

=Liquid piping Ф1/2 inch total length (ft)

l

5

=Liquid piping Ф3/8 inch total length (ft)

l

6

=Liquid piping Ф1/4 inch total length (ft)

l

1

=Liquid piping Ф22.22 mm total length (m)

l

2

=Liquid piping Ф19.05 mm total length (m)

l

3

=Liquid piping Ф15.88 mm total length (m)

l

4

=Liquid piping Ф12.70 mm total length (m)

l

5

=Liquid piping Ф9.52 mm total length (m)

l

6

=Liquid piping Ф6.35 mm total length (m)

Refilling amount (lbs)

= (l

1

x 0.237) + (l

2

x 0.168) + (l

3

x 0.114) + (l

4

x 0.074) + (l

5

x 0.036) + (l

6

x 0.015) + 2.2

Refilling amount (kg)

= (l

1

x 0.353) + (l

2

x 0.250) + (l

3

x 0.170) + (l

4

x 0.110) + (l

5

x 0.054) + (l

6

x 0.022) + 1.0

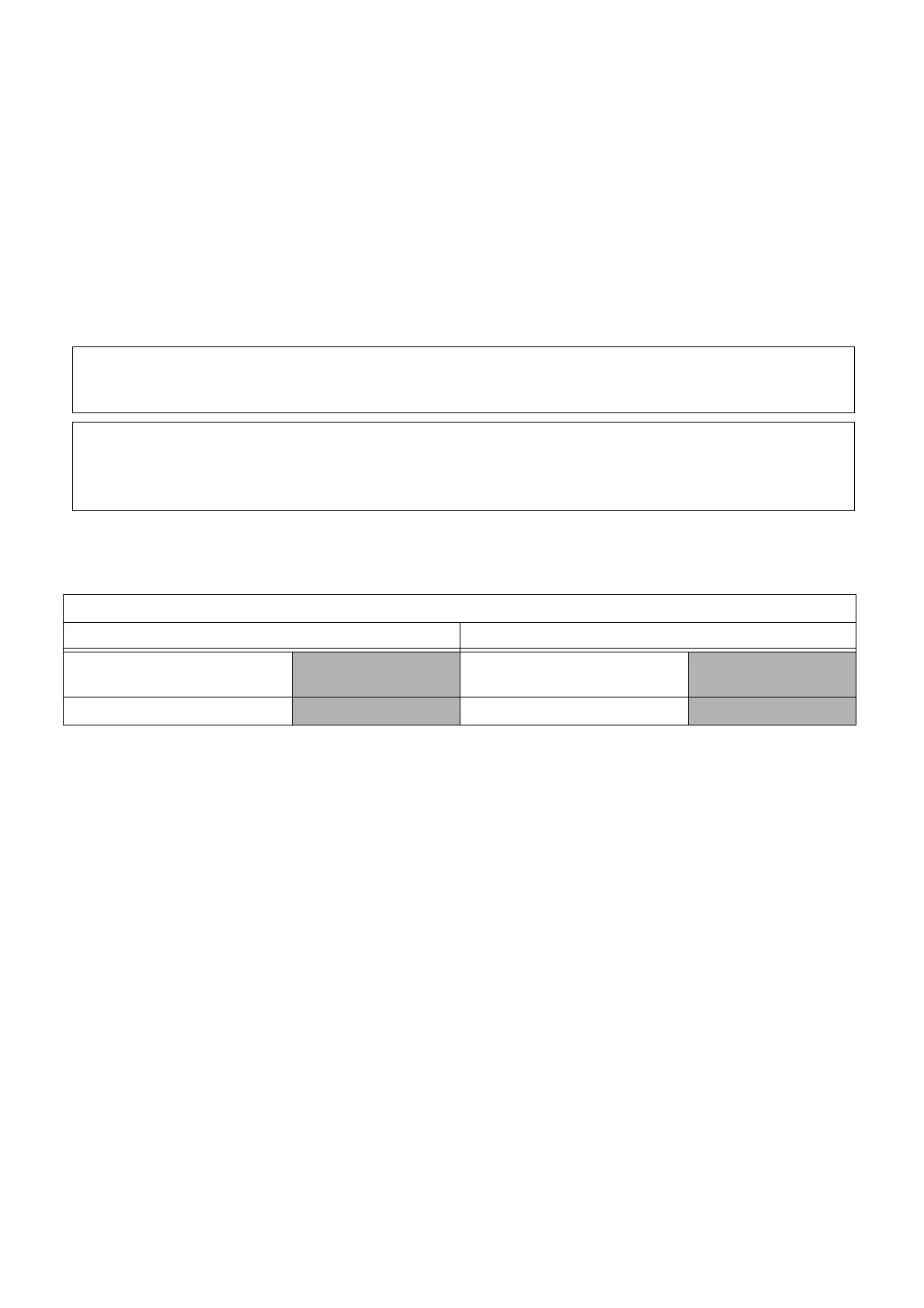

Belt tension※

Belt tension adjustment standard (Replacement) Belt tension adjustment standard (Inspection)

Sonic

Mechanical

(Reference value)

Sonic

Mechanical

(Reference value)

301 ~ 346 lbf (1,340 ~ 1,540 N)

202 lbf (900 N) 241 ~ 277 lbf (1,070 ~ 1,230 N) 162 lbf (720 N)

Loading...

Loading...