132

REPLACEMENT OF MAIN COMPONENTS

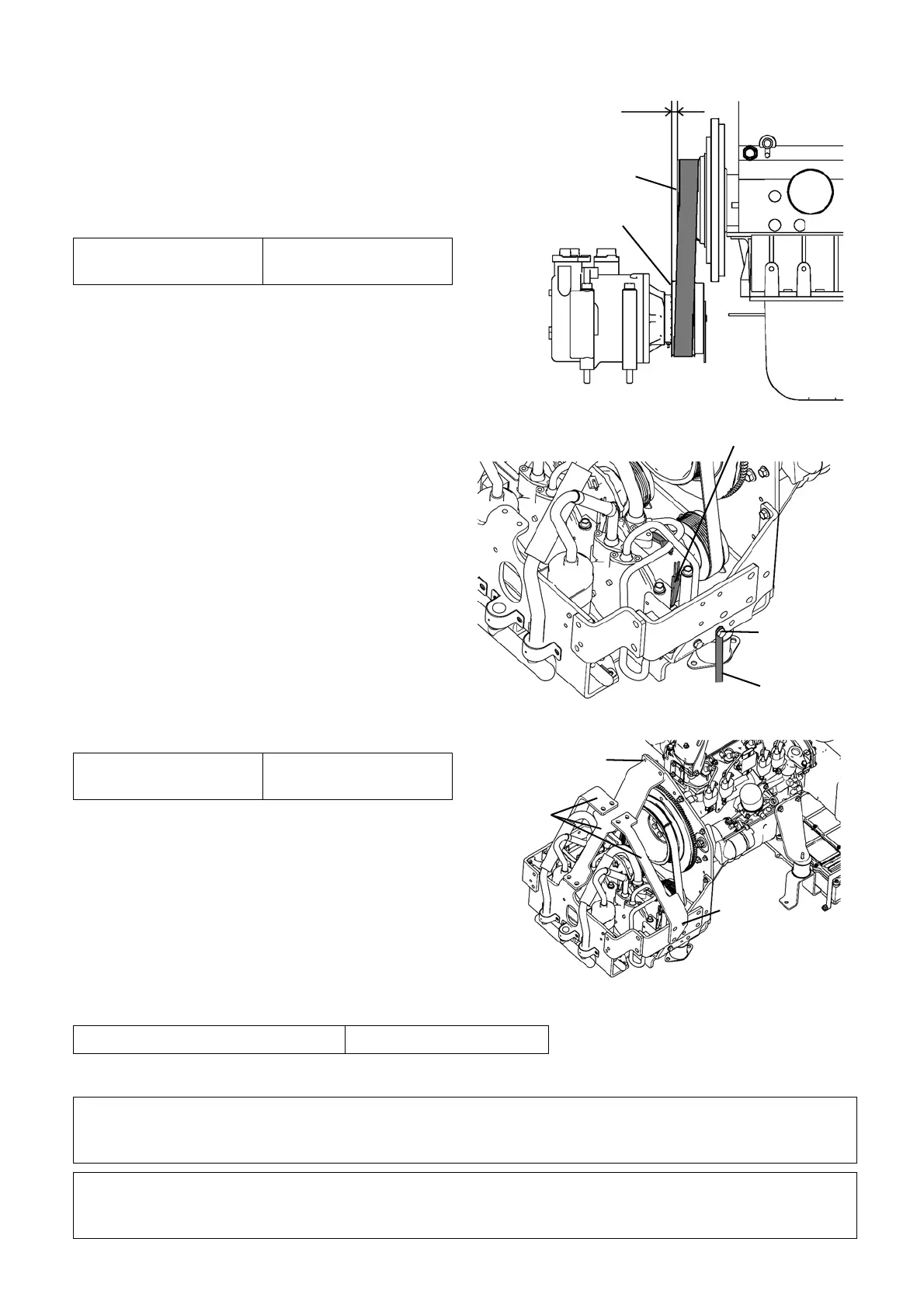

NOTE) Make sure that misalignment between the

edge line of the crank pulley groove and the

edge line of the compressor pulley groove is

1/8 inch (3 mm) or less when measured on the

crankshaft axis.

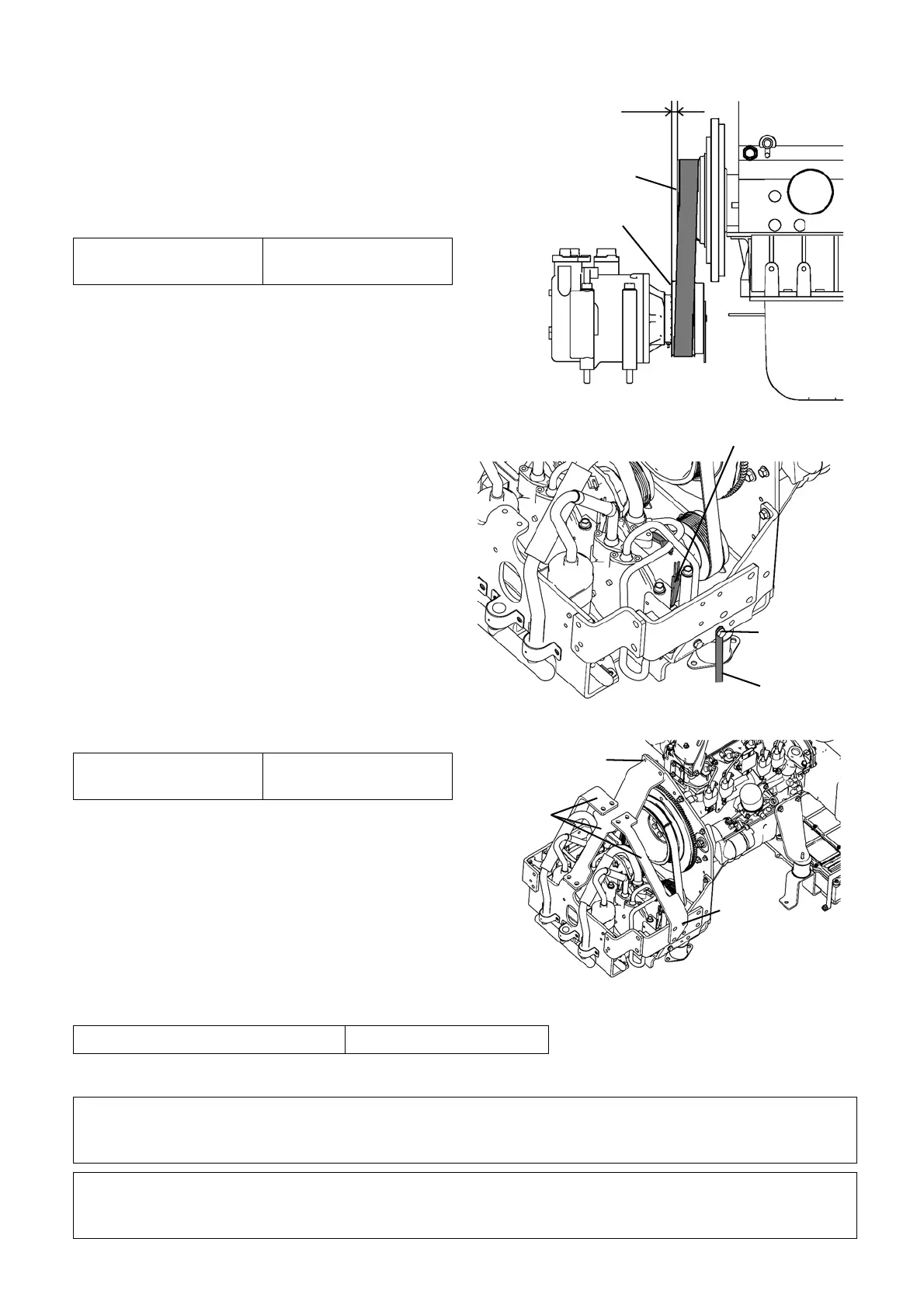

4) Tighten a locknut of the adjustment bolt.

5) Mount the grounding wire with a bolt.

6) Connect the connectors of the compressor heaters,

the clutch (No. 2 compressor only) and the electro-

magnetic compressor capacity valve.

7) Fix the wire harnesses to their original positions

with bundling bands.

8) Mount the 3 stays and tighten 15 bolts.

9) Refill the refrigerant oil as required.

11. After finishing vacuuming, refill the specified amount of refrigerant.

Calculate additional refrigerant refilling amount using the formula indicated below :

1/8 inch or less

Crank pulley

Compressor pulley

Tightening torque

7.4 ~ 11.1 lb·ft

(10 ~ 15 N·m)

Compressor heater

Grounding wire

Bolt

Bolts

Stays

Bolts

Tightening torque

31.0 ± 6.2 lb·ft

(42.0 ± 8.4 N·m)

Standard amount of refrigerant 37.5 lbs (17.0 kg)

Refilling amount (lbs)

= (l

1

x 0.237) + (l

2

x 0.168) + (l

3

x 0.114) + (l

4

x 0.074) + (l

5

x 0.036) + (l

6

x 0.015)

Refilling amount (kg)

= (l

1

x 0.353) + (l

2

x 0.250) + (l

3

x 0.170) + (l

4

x 0.110) + (l

5

x 0.054) + (l

6

x 0.022)

Loading...

Loading...