131

REPLACEMENT OF MAIN COMPONENTS

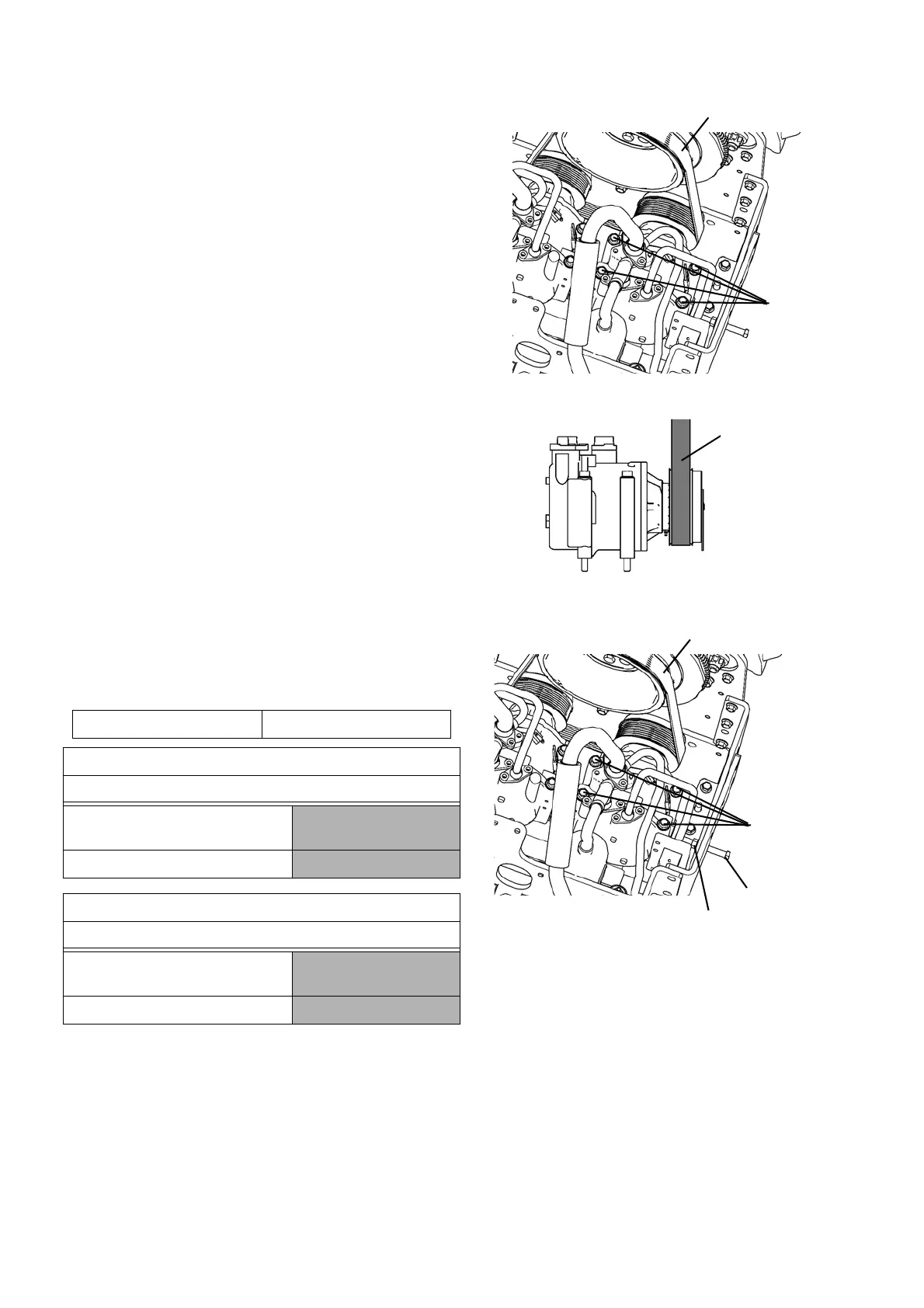

10. Perform the following work while vacuuming (operat-

ing the vacuum pump for 1 hour or longer after the

pressure drops to -14.65 psi (-101 kPa, -755 mmHg)

or lower).

1) Connect the oil tube to the oil tank.

2) Move the No. 1 compressor until the compressor

belt is tight, and tighten 4 bolts lightly.

NOTE) After mounting the compressor, tighten bolts

lightly before giving the tension to the com-

pressor belt, and check that the compressor is

in the correct position.

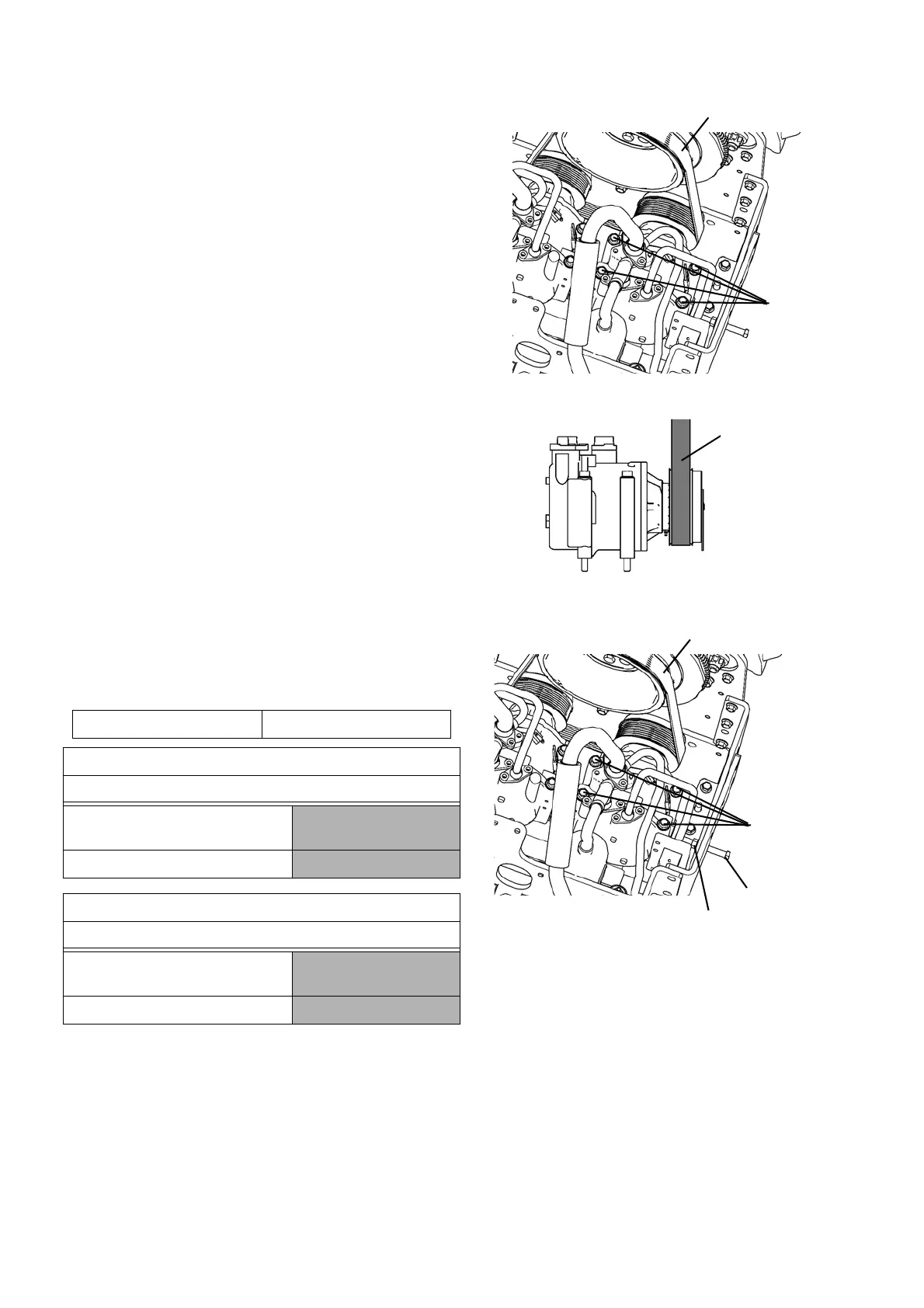

3) Slide the No. 1 compressor by turning the adjust-

ment bolt to give tension to the compressor belt.

Adjust the belt tension to the standard value, and

tighten 4 bolts firmly.

※ Measure the belt tension with a sonic belt tension gauge. Tension values for a mechanical belt tension gauge

on the chart are reference values.

Bolts

Compressor belt

Compressor belt

Bolts

Compressor belt

Locknut

Adjustment

bolt

Tightening torque 31.0 lb·ft (42 N·m)

Belt tension※

Belt tension adjustment standard (Replacement)

Sonic

Mechanical

(Reference value)

301~346 lbf (1,340~1,540 N)

202 lbf (900 N)

Belt tension※

Belt tension adjustment standard (Inspection)

Sonic

Mechanical

(Reference value)

241~277 lbf (1,070~1,230 N)

162 lbf (720 N)

Loading...

Loading...