IS-300A

4. How to Operate Screens

4-13

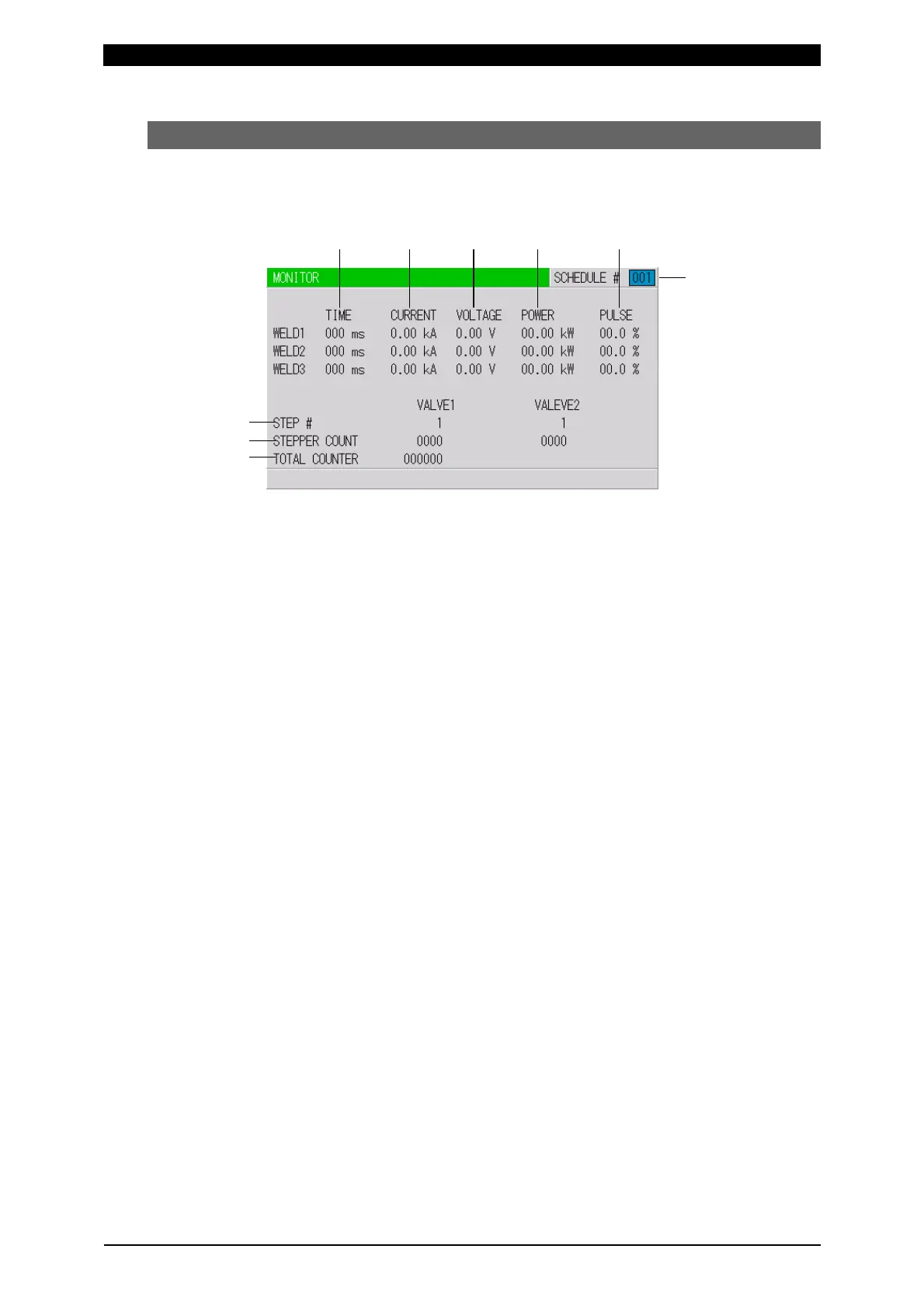

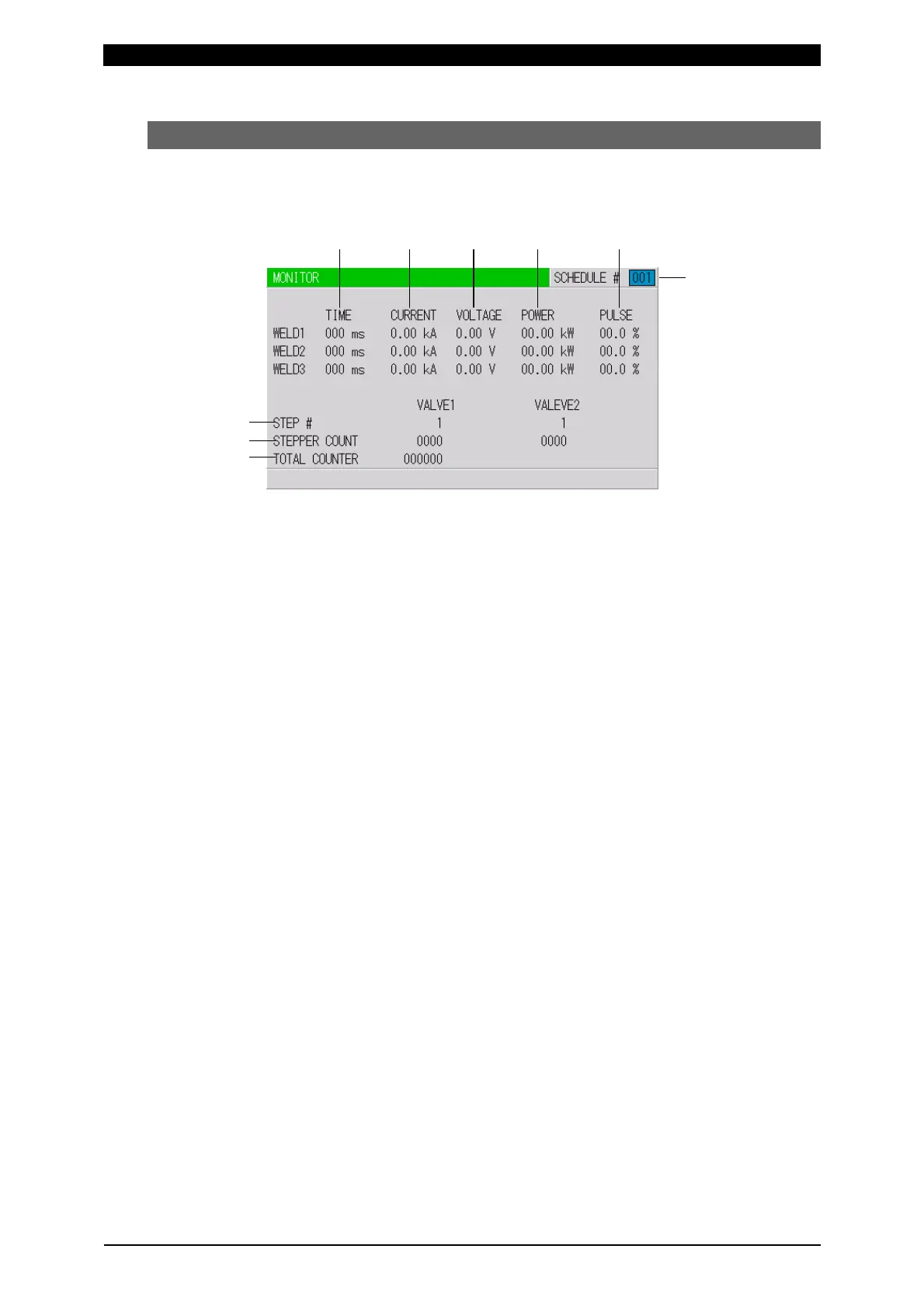

(4) MONITOR Screen

In this screen, you can confirm the operational conditions during welding.

Monitored data is displayed for each SCHEDULE.

(b) (c) (d) (e) (f)

(a) SCHEDULE #

Set the No. of the SCHEDULE to monitor. The measured values (welding current,

voltage, etc.) for welding within that SCHEDULE are displayed.

The Power Supply stores the latest measured values of each SCHEDULE No.

The stored measurement values are not erased even when the power is turned

off, and thus can be checked for the next job.

(b) TIME

The lengths of periods during which current was supplied in the course of

WELD1, WELD2 and WELD3 operations are displayed. As units of time, ms and

CYC may be selected. Either unit can be selected via the MODE SELECT screen.

(See (9)(e).)

(c) CURRENT

The welding current is displayed.

(d) VOLTAGE

The measured voltage is displayed when the voltage detecting cable is

connected and the secondary voltage is input.

(e) POWER

The measured electric power (measured current x measured voltage) is

displayed when the toroidal coil and voltage detecting cable are connected and

the secondary current and secondary voltage are input.

(f) PULSE

The widest pulse among the supplied primary pulse current is displayed as a

percentage of pulse width in full wave mode. The pulse width in full wave mode

varies with the frequency setting (WELD TRANS FREQ).

(Note) The value displayed on the MONITOR screen is the average of value

sampled at each welding pulse. Therefore, the value may differ from the

measurement value of our weld checker.

(g)

(h)

(i)

(a)

Loading...

Loading...