1-52

Released:01/2014

E-mail: service@amfreece.cz; webside: amfreece.com

Phone: +420 582 309 146; Fax: +420 582 360 606

E - STANDARD MACHINE ADJUSTMENT

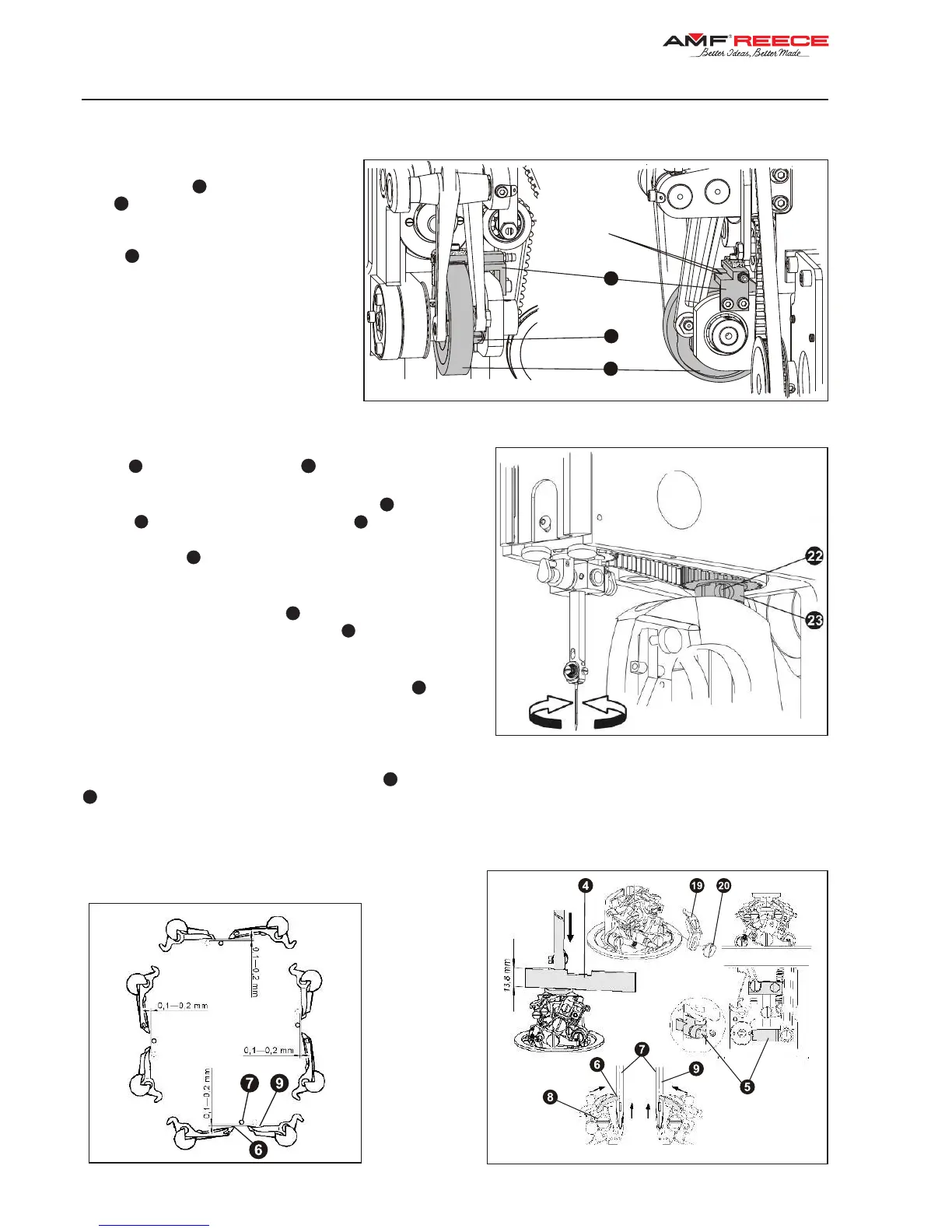

10. SPREADER AND LOOPER CAM ADJUSTMENT

Locate the cam

when the needle bar is in the

lowest position according to the section

E3, point 2. To turn a cam, loosen the

screw

.

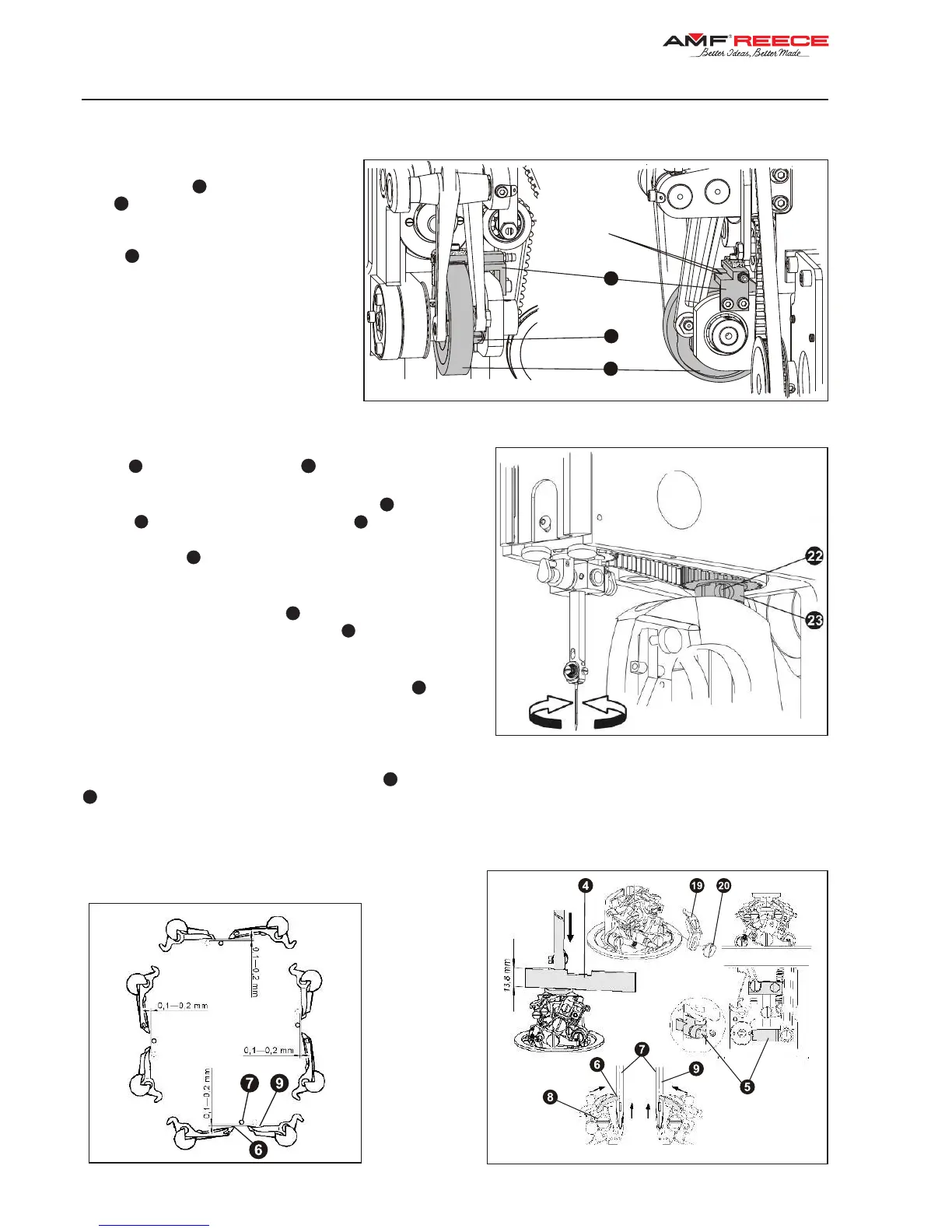

11. LOOPERS ADJUSTMENT

11.1. To perform this adjustment, remove the plates and

holder

.

11.2. After the loosening the bracket screws

on the axis of the needle

. By turning the

handwheel, raise the needle bar from the lowest position, to

insert a gauge

by its higher end between gauge support

and the needle bar end.

11.3. After loosening the screw

adjust the distance 0.1 - 0.2

mm between the needle and looper tip

. Tighten the screw

again.

11.4. Adjust the same space on the right looper

when it

passes the needle. To perform it, turn the hand wheel.

11.5. It is important to check the looper distance, according to

the point 11.3. Different distance is necessary to adjust by

turning the needle bar after loosing the screw

.

11.6. The correct distance between the loopers and needle has

to be checked in 4 positions of needle bar plus race. Please

see the drawing above.

Gaude line

Loading...

Loading...