S-311

1-67

Released:01/2013

E-mail: service@amfreece.cz; webside: amfreece.com

Phone: +420 582 309 146; Fax: +420 582 360 606

F - MACHINE MAINTENANCE

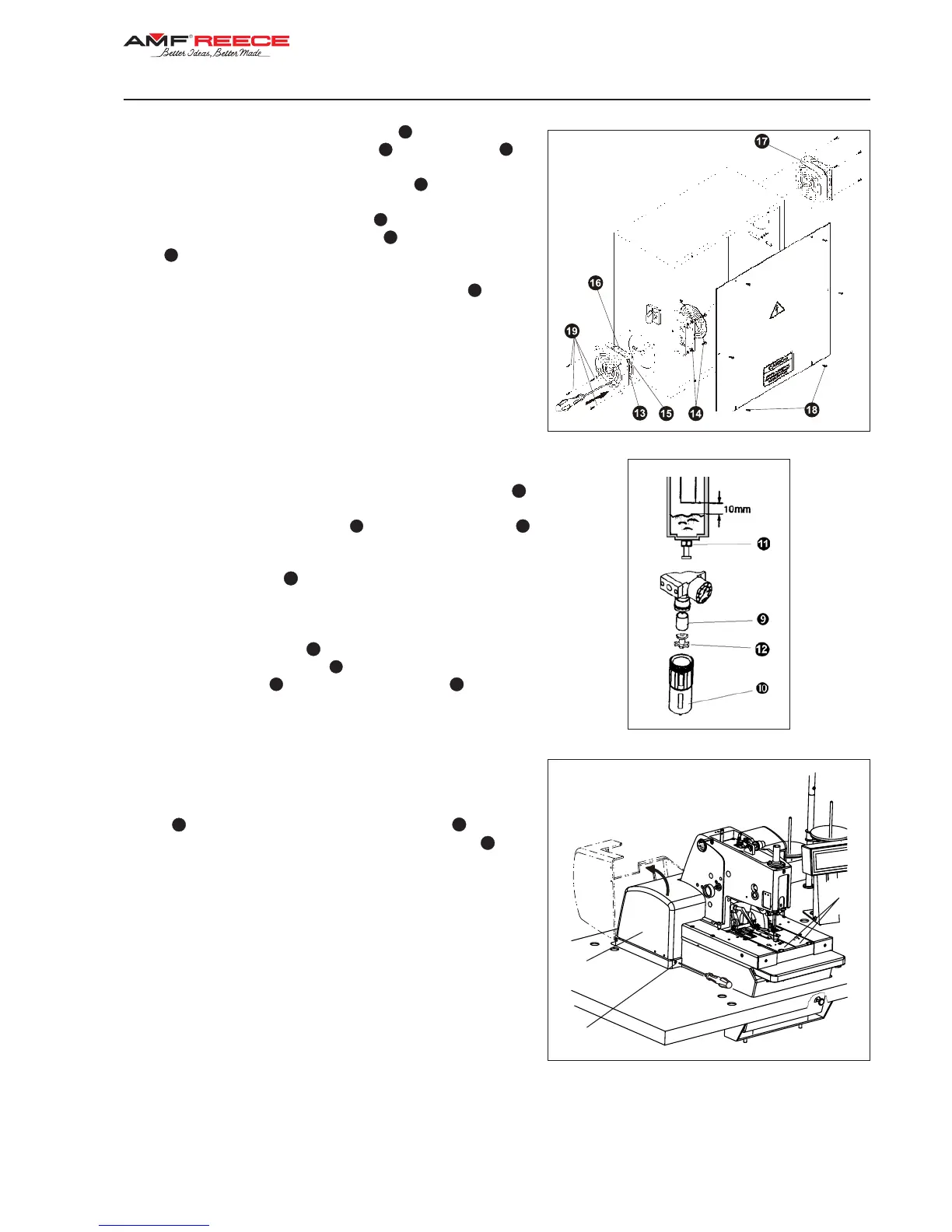

1.6. Using a screwdriver, loosen the locks

on the control box

door. Using a wrench, loosen 4 screws

.

CAUTION!

When loosening the last screw, hold the fan

by hand inside

the control box to prevent it from dropping into the control box.

Insert the screwdriver into the rack

and by pushing the

screwdriver through the cleaning pad

. Remove the cleaning pad.Remove the dust from the

cleaning pad or in case of considerable dirt, wash it using a mild

detergent.Perform the same cleaning on the rear fan

.

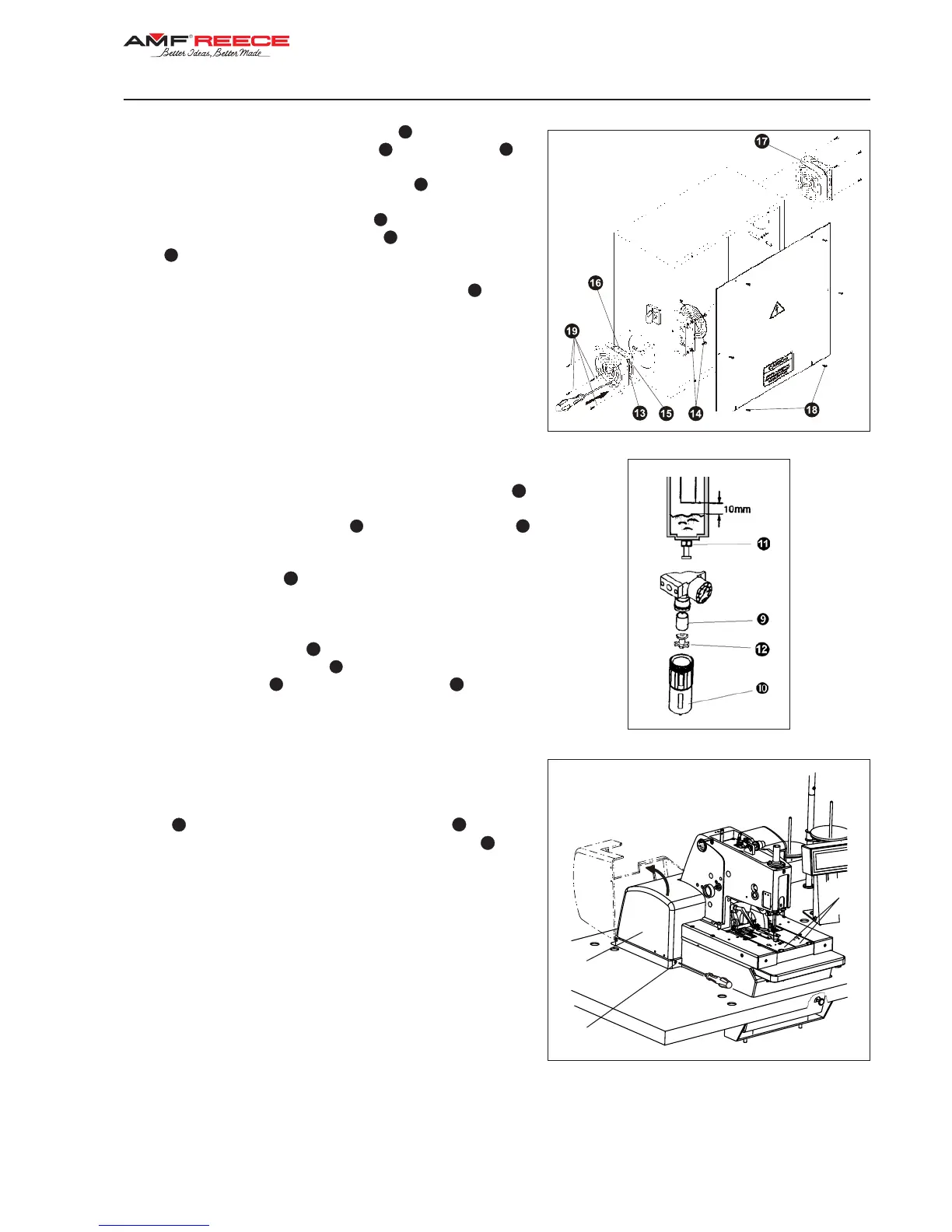

1.7. Maintenance of air regulator contains check of the

condensate

andpossiblereplacementofthelterelement

.

Thelevelofcondensate must be 10 mm below the lter

inside of the desliming receptacle

signalizes this height.

Open the bleeder screw

by turning it counter clockwise. The

condensatecanthenowout.Tightenthescrewagain.

With worse ow despite same pressure setting

replace the lter element

after stopping the air supply.

Unscrew desliming receptacle

anticlockwise and ventilate.

By unscrewing the nut

,loosenthelterelement

, place the

new one and assemble the device in reverse order.

1.8. Perform visual check of mechanism especially in area of

sewing mechanism. Make sure that in this area are not any

scraps of threads and fabric.

1.9. Whenthemaintenanceandcheckingisnished, close

covers

, folding cover lock by the locking screw

, put back

the clamp plates and lock them by clamp support plates

, then

continue with work.

Loading...

Loading...