D41 39

Type of bitumen

Laying temperature (°C)

Minimum temperature for the first

roller pass

(°C)

B 65/60 140 – 180 above 120

B 80/100 130 – 170

B 200/180 120 – 160

B 300/200 110 – 150 above 100

End of a layer

To obtain a well finished edge across the entire width of the layer, one must know

how to correctly end the layer. It is well known that, when ending a layer, a right

angled, vertical edge should be made to obtain a good connection line across the

entire width of the layer. There are different methods for ending a layer at right

angles and obtaining a well finished edge.

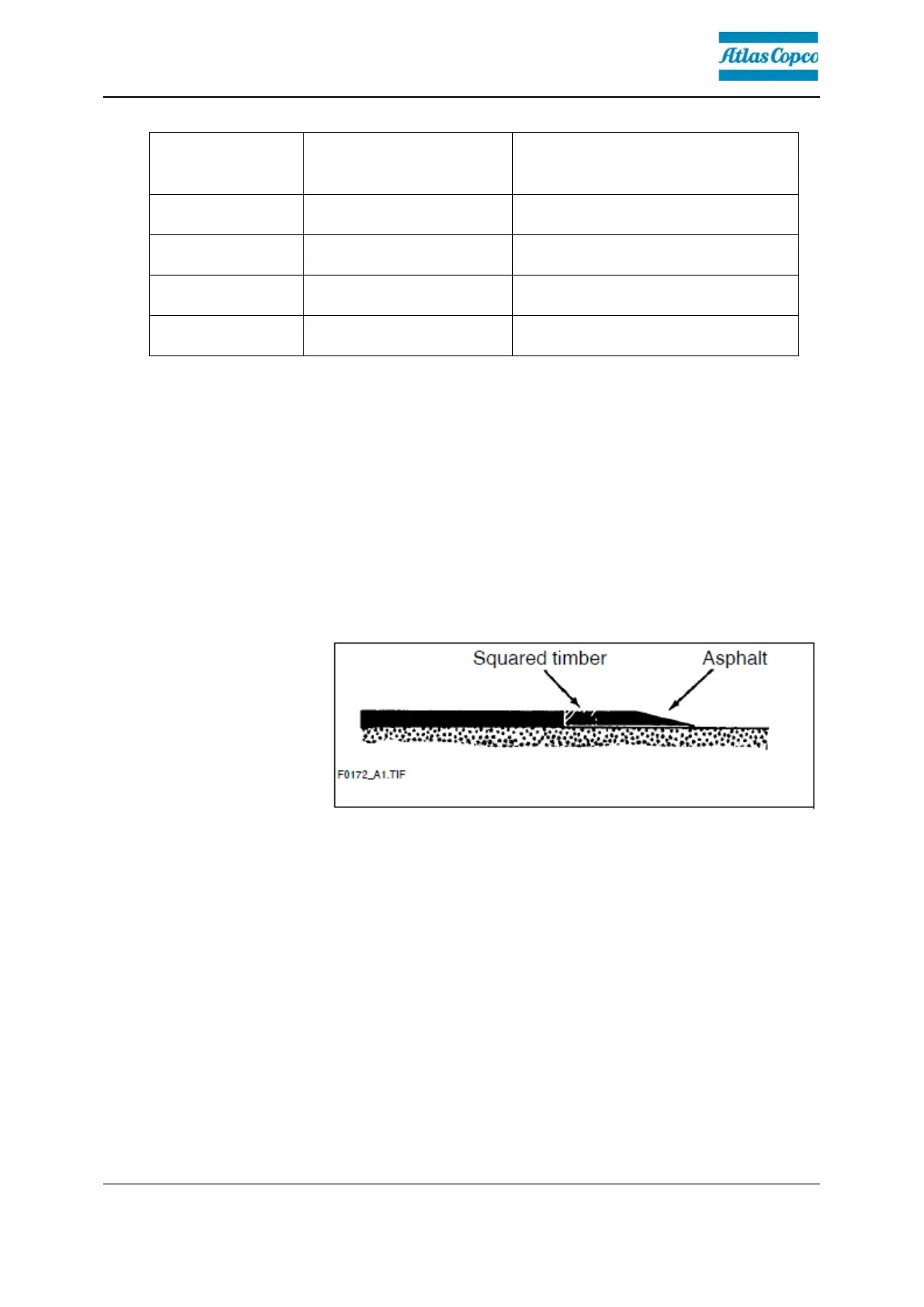

1. One method often used is to place a piece of timber with a width matching the

thickness of the compacted layer in front of the end of the layer.

At the end of the layer, the operator should adjust the conveyor and the auger in

such a manner that the material will be evenly distributed in front of the screed.

Then the conveyor must be stopped and the paver finisher must be moved

forward. As soon as a part of the screed has been emptied, the paver finisher

must be stopped and the screed lifted. Then, a right angled gap is created along

the edge of the layer and a piece of timber is placed into this gap. To keep the

piece of timber in position, material must be pushed against the timber.

After the layer has been rolled and consolidated, the piece of timber can be

removed. In this way, a right angled edge is created against which the next

section can be properly closed up.

2. Another method often used to end a layer or move a roller to the beginning of a

layer is to manually hovel a right angled gap, finish the end and insert a piece of

resin board. The resin board is then covered by asphalt, thus forming a ramp for

Loading...

Loading...