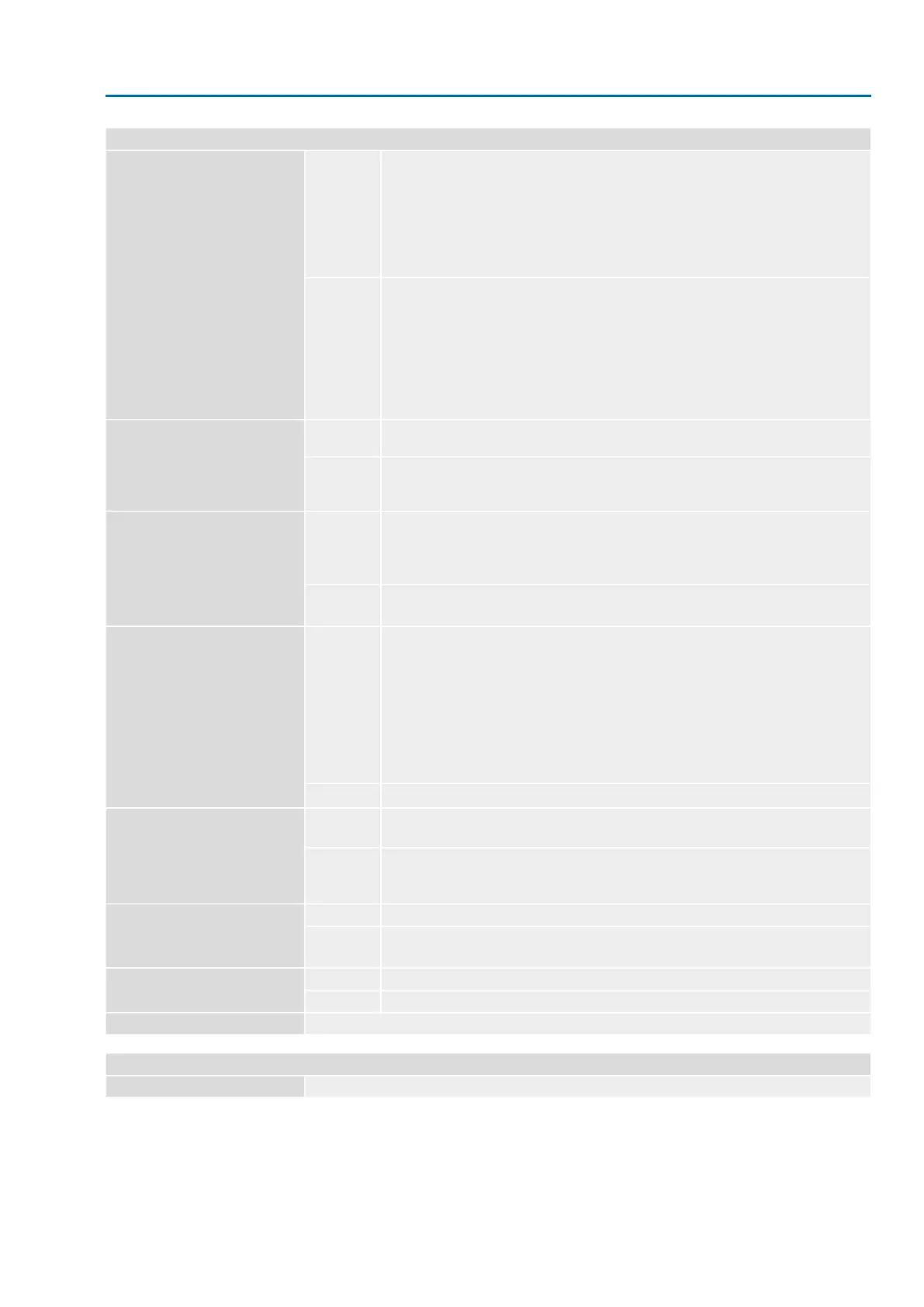

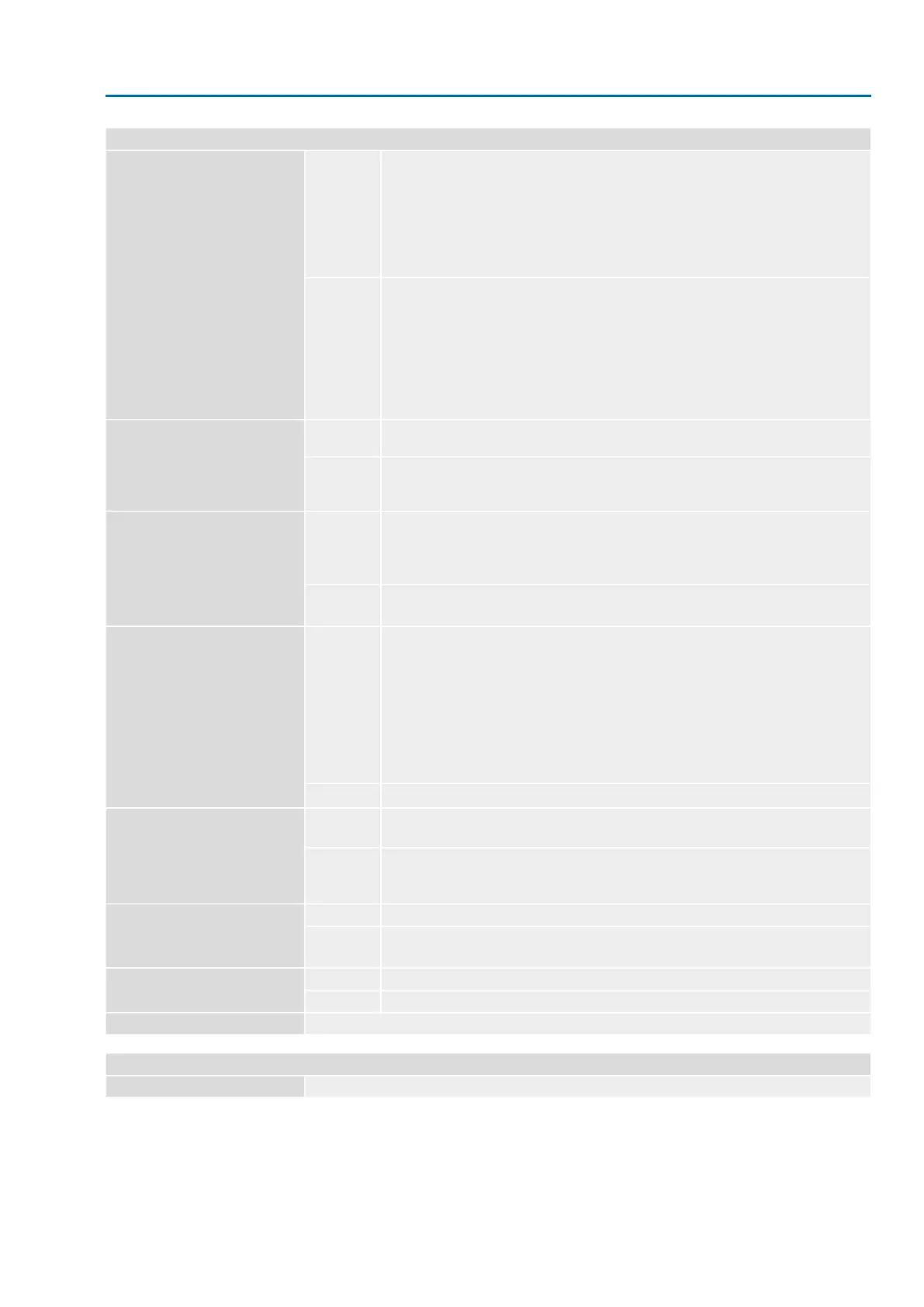

Features and functions

5 output contacts:

●

4 NO contacts with one common, max. 250 V AC, 0.5 A (resistive load)

-

Default configuration: End position CLOSED, end position OPEN, selector switch

REMOTE, selector switch LOCAL

●

1 potential-free change-over contact, max. 250 V AC, 0.5 A (resistive load) for collective

fault signal

-

Default configuration: Torque fault, phase failure, motor protection tripped

Standard:Status signals

(output signals)

5 output contacts with integrated running indication(blinking) for directions OPEN and

CLOSE in combination with blinker transmitter

●

4 NO contacts with one common, max. 250 V AC, 0.5 A (resistive load)

-

Default configuration: End position and running indication CLOSED, end position

OPEN, selector switch REMOTE, selector switch LOCAL

●

1 potential-free change-over contact, max. 250 V AC, 0.5 A (resistive load) for collective

fault signal

-

Default configuration: Torque fault, phase failure, motor protection tripped

Options:

Auxiliary voltage 24 V DC ±5 %, max. 50 mA for supply of control inputs, galvanically

isolated from internal voltage supply

Standard:Voltage output

115 V AC ±10 %, max. 30 mA for supply of the control inputs, galvanically isolated from

internal voltage supply

(Not possible in combination with PTC tripping device)

Option:

●

Selector switch LOCAL - OFF - REMOTE (lockable in all three positions)

●

Push buttons OPEN, STOP, CLOSE

●

3 indication lights: End position CLOSED (yellow), collective fault signal (red), end

position OPEN (green)

Standard:Local controls

●

Protection cover, lockable

●

Special colours for the 3 indication lights

Options:

●

Selectable type of seating, limit or torque seating for end position OPEN and end po-

sition CLOSED

●

Overload protection against excessive torques over the whole travel

●

Excessive torque (torque fault) can be excluded from collective fault signal.

●

Phase failure monitoring with automatic phase correction

●

Push-to-run operation or self-retaining in REMOTE

●

Push-to-run operation or self-retaining in LOCAL

●

Blinker signal from actuator (option) for running indication via indication lights of local

controls can be activated/deactivated.

Standard:Application functions

●

Positioner for Split Range operation (requires position transmitter in actuator)Options:

●

Monitoring the motor temperature in combination with thermoswitches within actuator

motor

Standard:Motor protection evaluation

●

Additional thermal overload relay in the controls in combination with thermoswitches

within the actuator

●

PTC tripping device in combination with PTC thermistors within actuator motor

Options:

AUMA plug/socket connector with screw-type connectionStandard:Electrical connection

●

Terminals or crimp connection

●

Gold-plated control plug (sockets and plugs)

Options:

Metric threadsStandard:Threads for cable entries

Pg-threads, NPT-threads, G-threadsOptions:

Refer to name plateWiring diagram

Further options for version with electronic position transmitter in actuator

Analogue output E2 = 0/4 – 20 mA (load max. 500 Ω)Position feedback signal (option)

71

SA 07.2 – SA 16.2 /SAR 07.2 – SAR 16.2

AM 01.1/AM 02.1 Technical data

Loading...

Loading...