3-15

Chapter 3 Starting and Stopping this Device

(iv) Introducing process pressure and checking for leaks

In the following procedure, process pressure is introduced into the pressure-receiving part of this device.

Procedure

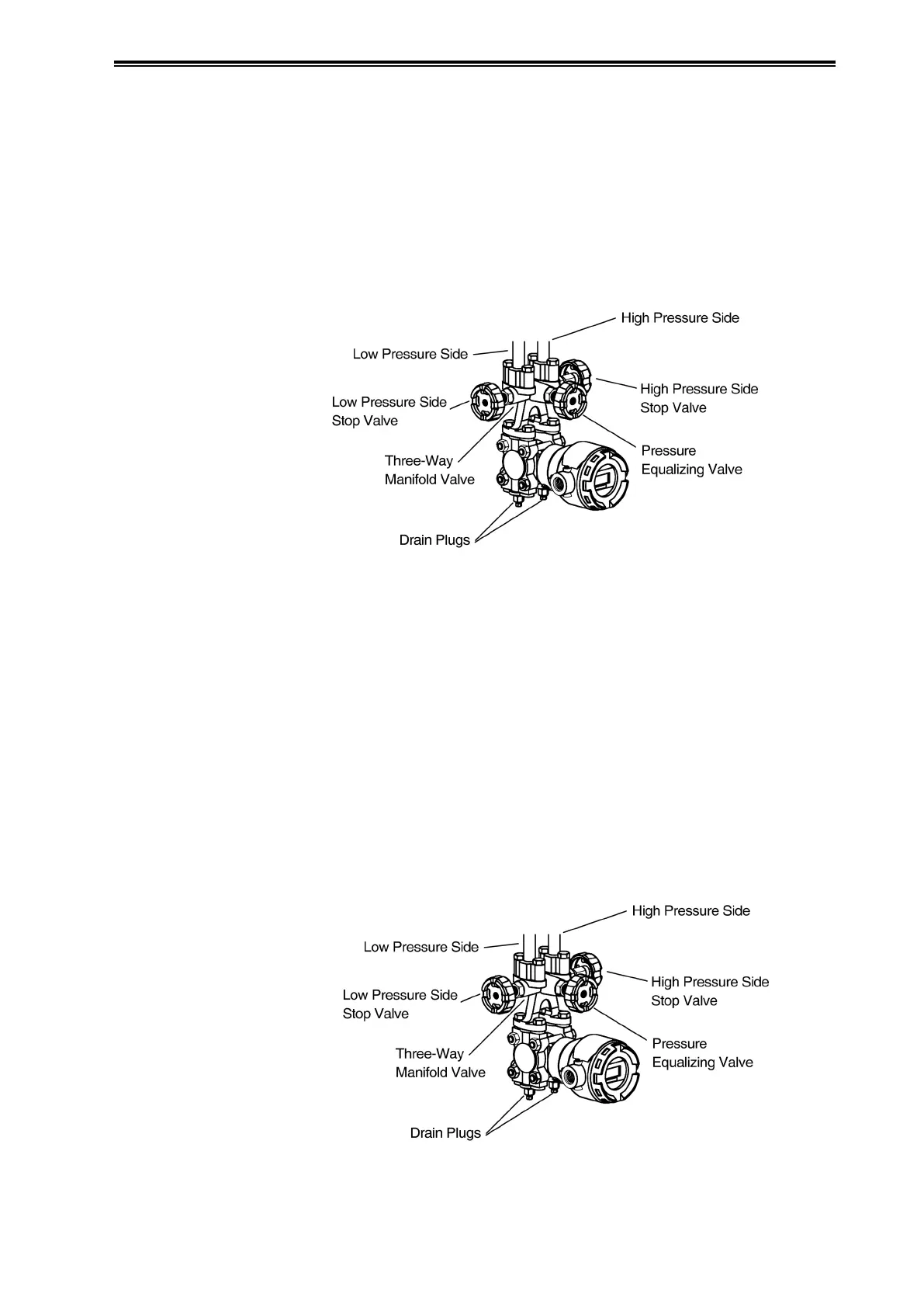

(1) (1) Open the master valves (see Figure 2-39), and introduce process fluid into the

connecting pipe. If the process temperature is high at this point, wait until the connecting

pipe cools down.

(2) Gradually open the high pressure side stop valve, and fill with process fluid. When full,

close the high pressure side stop valve.

(2) Check that there are no pressure leaks in the connecting pipes, the three-way manifold valve,

the device itself, etc.

(2) Starting Operation

(i) Applying process pressure

In the following procedure, valves are operated to apply the differential pressure of the process to

this device, and then the measured values are checked using the communicator.

Procedure

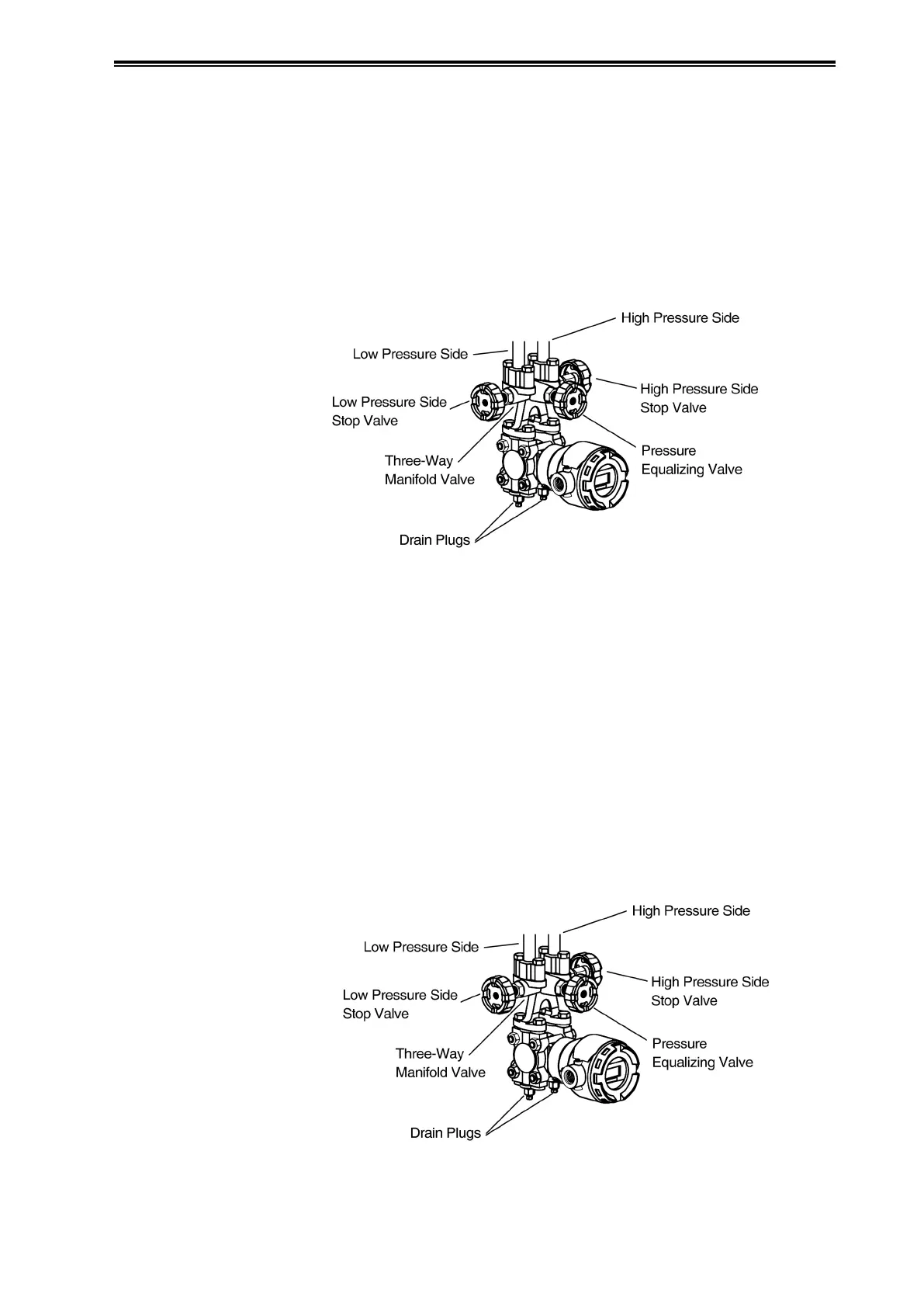

(1) Check that the valves of the three-way manifold valve are in the following state.

(1) High pressure side stop valve: fully closed

(2) Low pressure side stop valve: fully open

(3) Equalizer valve: fully closed

(2) Gradually open the high pressure side stop valve, and introduce process pressure.

Loading...

Loading...