15

© Copyright by BIFFI Italia. All rights reserved.

“ICON2000”

instruction and operating manual

2.1.2. RE-ASSEMBLING THE INTERNAL PARTS

It is advisable to wash the dismantled parts with a suitable solvent; dry them with

compressed air; make sure there are no metal filings or foreign bodies; spread a film of

grease on all parts (for grease type, see Sect. 618/1 chapt. D).

Proceed with the assembly of the internal parts following the reverse order of the

disassembly; tighten the lower ring nut with thread sealant LOCTITE 270 or equivalent,

making sure the stem nut still rotates freely; fix the unit to the gear reducer as described

further on.

2.2 TYPE “B1” AND “B2” COUPLING BLOCKS

2.2.1 PREPARING THE BUSHING

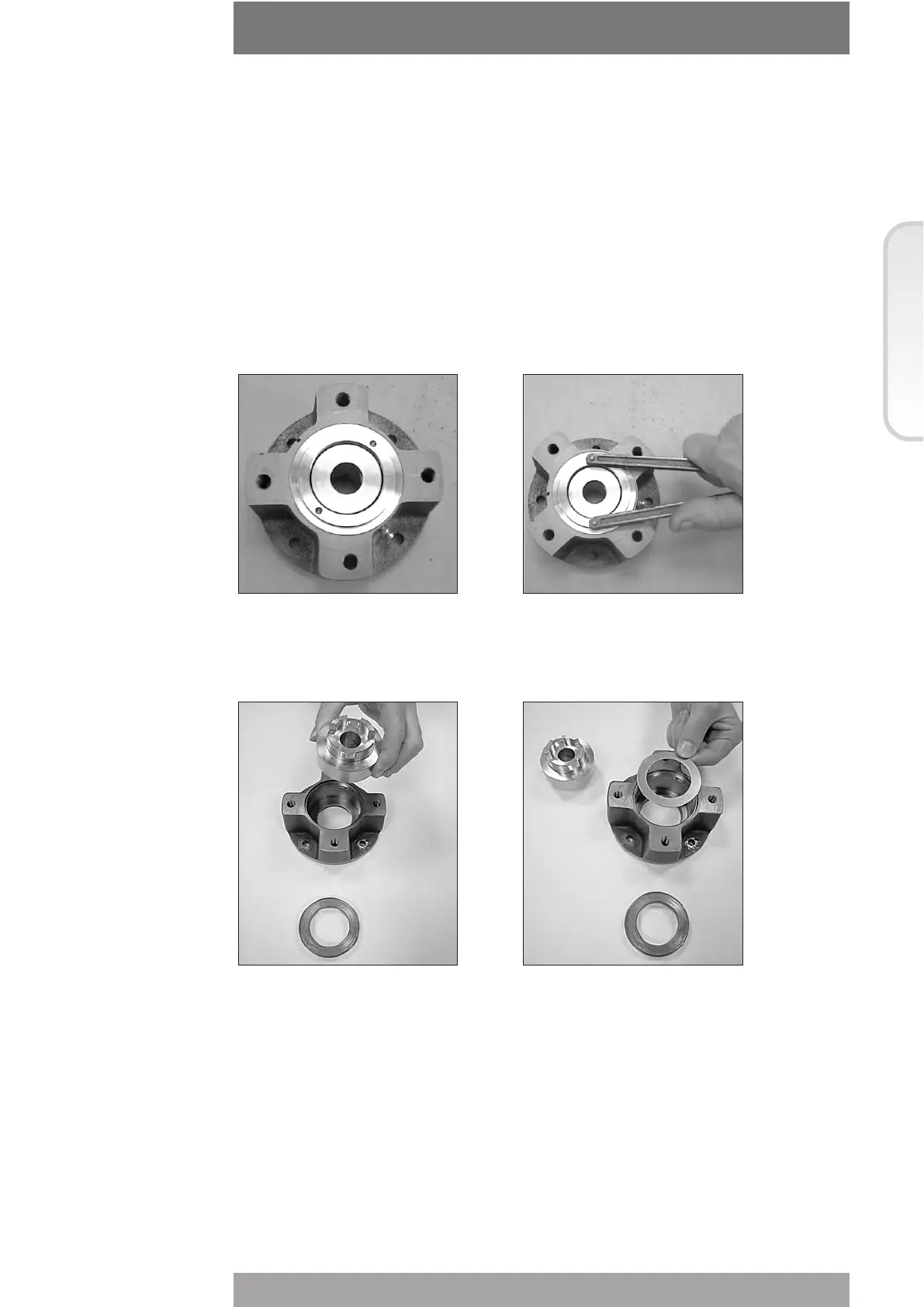

With a compass key, unscrew the lower ring nut.

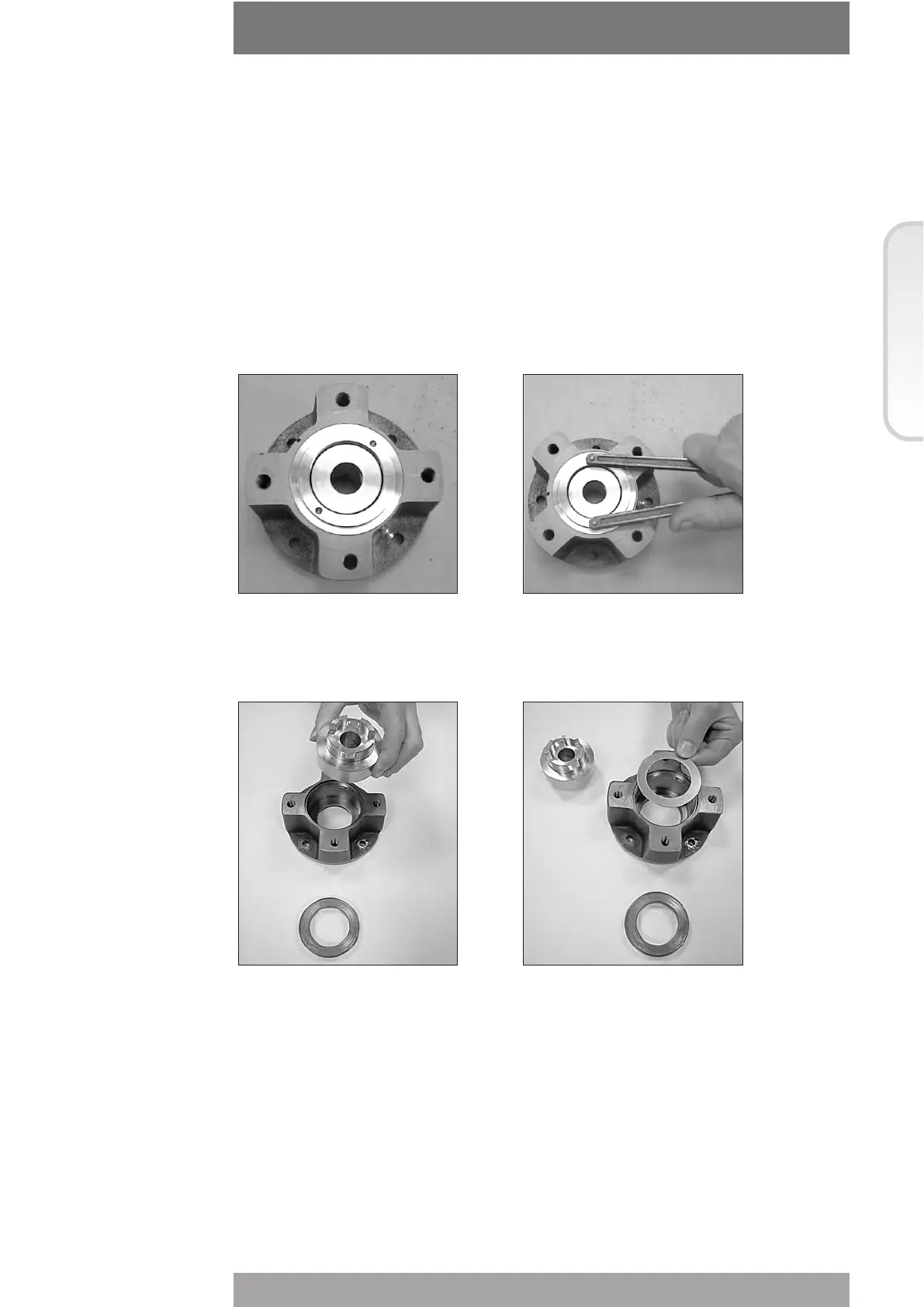

Extract the bushing from the block housing.

The internal thrust washer will remain at the bottom of the block housing.

Now the bore can be machined in the bushing to suit coupling requirements.

The same procedure is also used for possible maintenance.

2.2.2 RE-ASSEMBLING THE INTERNAL PARTS

It is advisable to wash the dismantled parts with a suitable solvent; dry them with

compressed air; make sure that there are no metal filings or foreign bodies; spread a film of

grease on all parts (for grease type, see Sect. 618/1 chapt. D).

Proceed with the assembly of the internal parts following the reverse order of the

disassembly; tighten the lower ring nut with thread sealant LOCTITE 270 or equivalent,

making sure the bushing still rotates freely; fix the unit to the gear reducer as described

further on.

Section 618/1 chapt. C

Section 618/1

Loading...

Loading...