53

Make sure the downshute can move freely and that no fertilizer deposits or anything

else is jammed against the motor regulating the downshute position.

Restart the computer to reset the alarm.

If the error message continues and the downshutes’ working areas are unobstructed,

and nothing is jammed, the actuator could be defective and need to be replaced.

> Right (left) actuator blocked

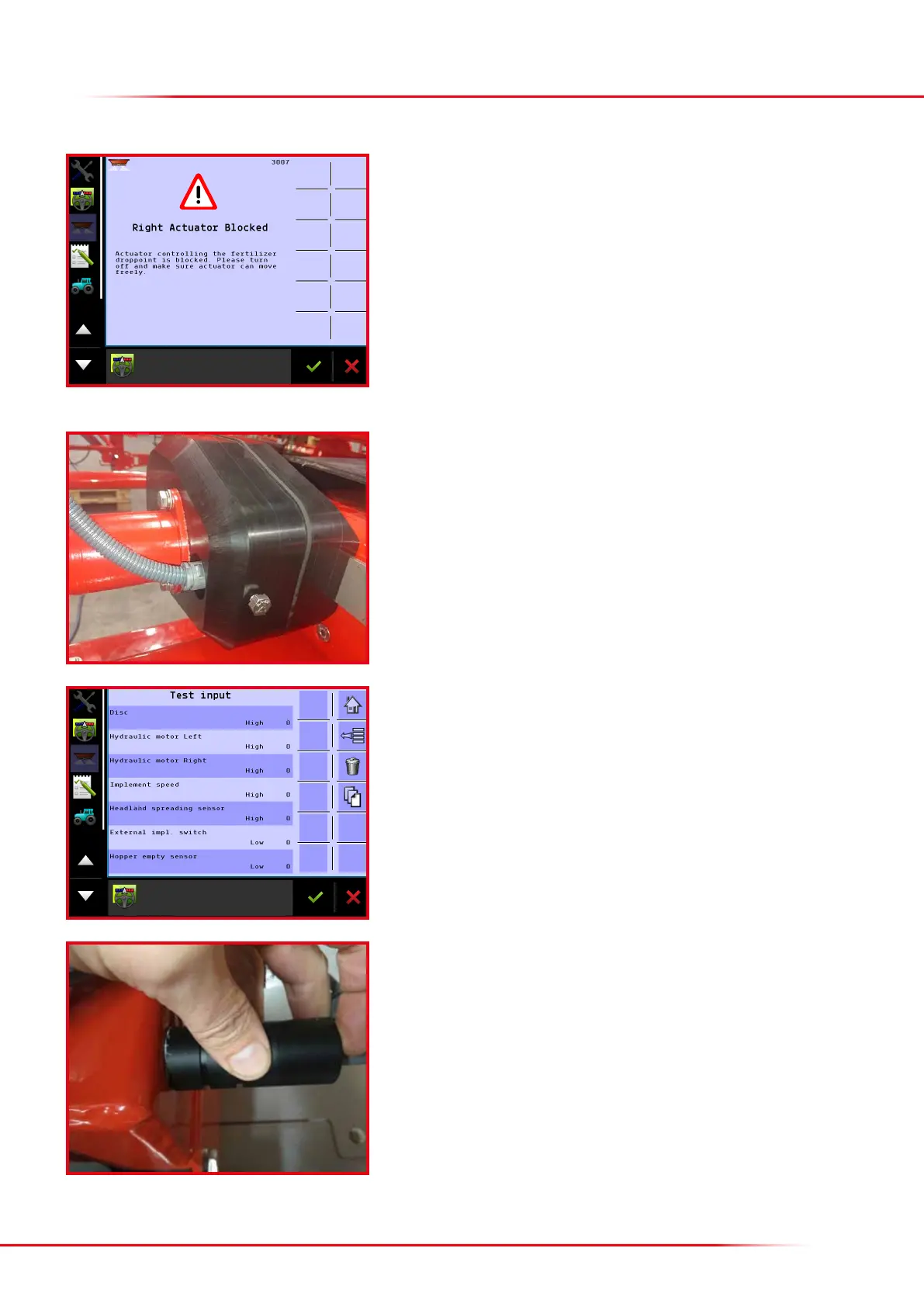

It is possible to check a sensor’s function. If a sensor does not count or if it counts

incorrectly, it is oen the pick-up distance, i.e. the distance between the sensor and the

tooth being scanned, that is too great. The pick-up distance of the gearboxes’ sensors

is 1–1.5 mm, so if the sensor is not close enough to the gearbox cogwheel, it cannot

detect the teeth and therefore will not send a signal to the computer.

Press the sensor on the gearbox as far as possible into its installation hole. It is held

in place by an 8 mm screw. Loosen the screw and make sure the sensor is pressed in

as far as possible. It may be necessary to rotate the sensor slightly as it will otherwise

tend to return to the same position when the screw holding it in place is retightened.

Check whether the sensor is working by holding it against a piece of metal. In the

terminal, select “Test input” (Home – Menu – Help – Diagnostic – Test input). Now all

inputs from the implement’s sensors will be viewable.

By holding the gearbox sensor against a piece of metal, the input in the terminal’s

test menu will change and an impulse will be counted. If the input does not switch

between high and low and if impulses are not counted, the sensor is either defective

or is not being supplied with power (12 V). If there is no power, the implement’s other

sensors will not work either.

If the gearbox sensor is defective, it must be replaced by the same type of new sensor

(Bredal order no.: 01023137).

> Checking the gearbox sensor

Loading...

Loading...