65

OTHER MAINTENANCE AND CLEANING

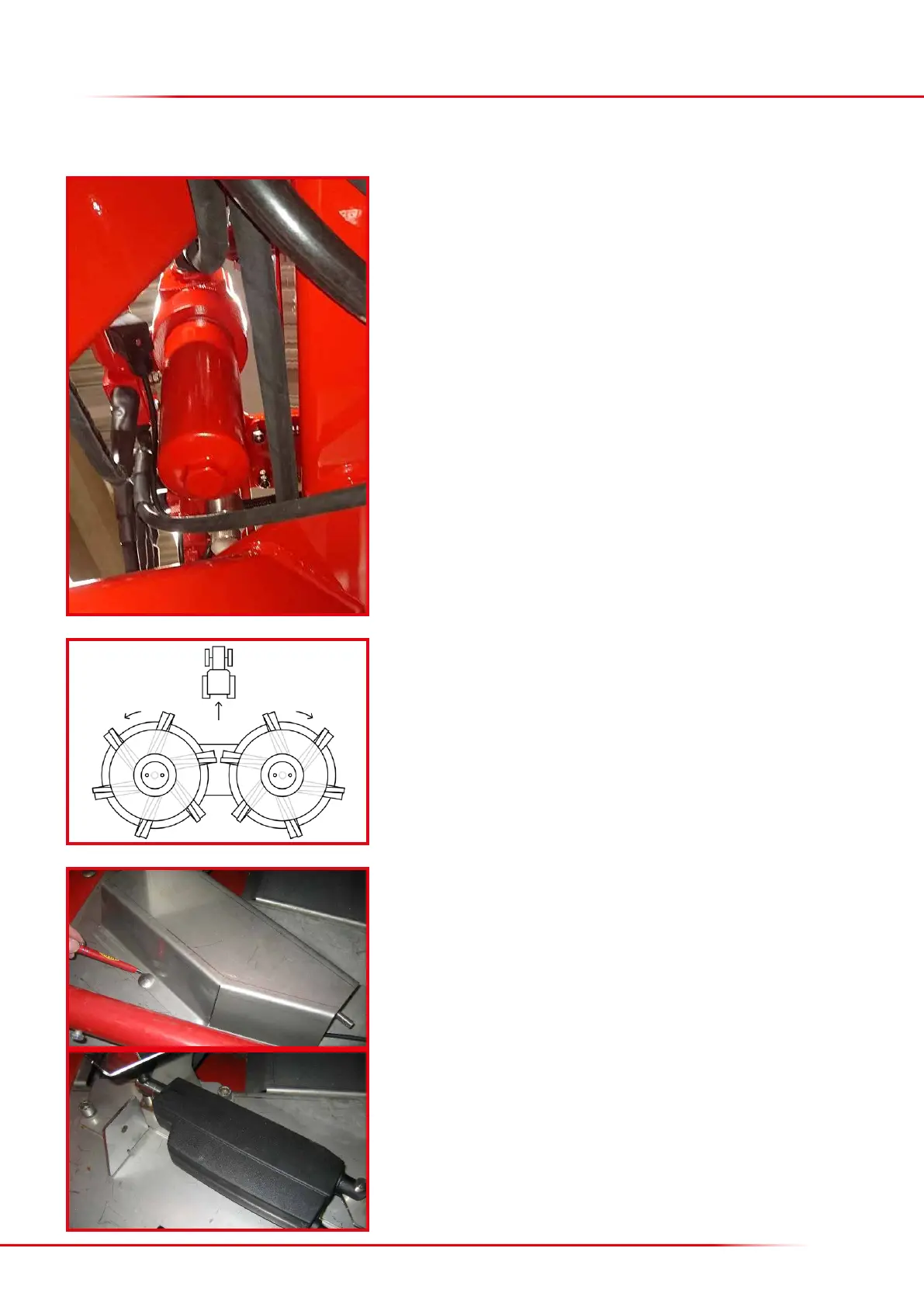

The spreader’s hydraulic system for operating the belts is tted with an oil lter. The

lter’s replacement interval largely depends on the operating conditions, and the

meticulousness with which the tractor’s hydraulic system is kept clean, but it is advisable

to replace the lter every two to four years.

The oil lter is placed in under the spreader and it is easiest to access it from the

front end of the spreader >.

> Oil filter

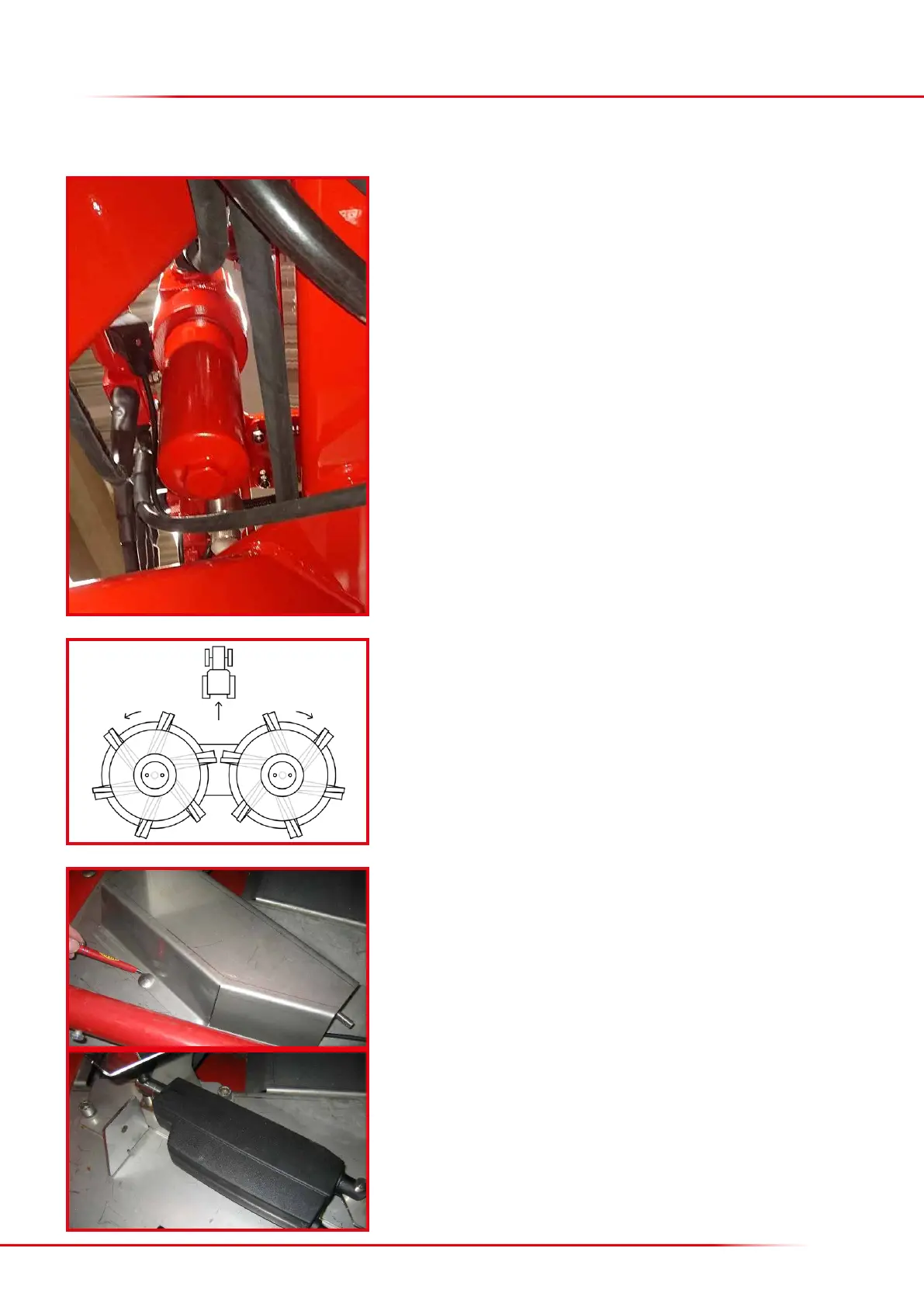

The electrical actuators controlling the downshutes are protected by a stainless steel

shield. The shield only protects them against mechanical impacts but does not prevent

fertilizer and dust from getting in. Therefore, remove the shield regularly and clean

around the actuators. This should always be done before washing or prolonged idle

periods. NEVER use water for cleaning if the shield has been removed.

> Actuators

Check that the spreading system is clean and in working order every day. Insucient

cleaning or worn-out spreading booms can result in poor spreading patterns.

Certain types of fertilizer and humid weather can create coatings on downshutes and

spreading vanes, so these should be inspected and cleaned regularly during operation.

Replace the spreading vanes if holes are worn into them. It is very important that

the spreading vanes are correctly mounted on the spreading discs, as

shown in the drawing.

> Spreading system

Always be careful when washing with a high-pressure washer and never spray directly

on bearings, sensors, etc.

Before winter storage, clean the spreader carefully and apply a layer of rust-protective

oil to the implement. Be careful not to apply oil on the rubber belt as this will

dissolve the rubber. It is advisable to rst spread a layer of cat litter or sawdust on

the belt to absorb excess oil. Remember to remove the material aer four or ve days

once all the oil has been absorbed.

> Washing and storage

Loading...

Loading...