62-11640 8–30

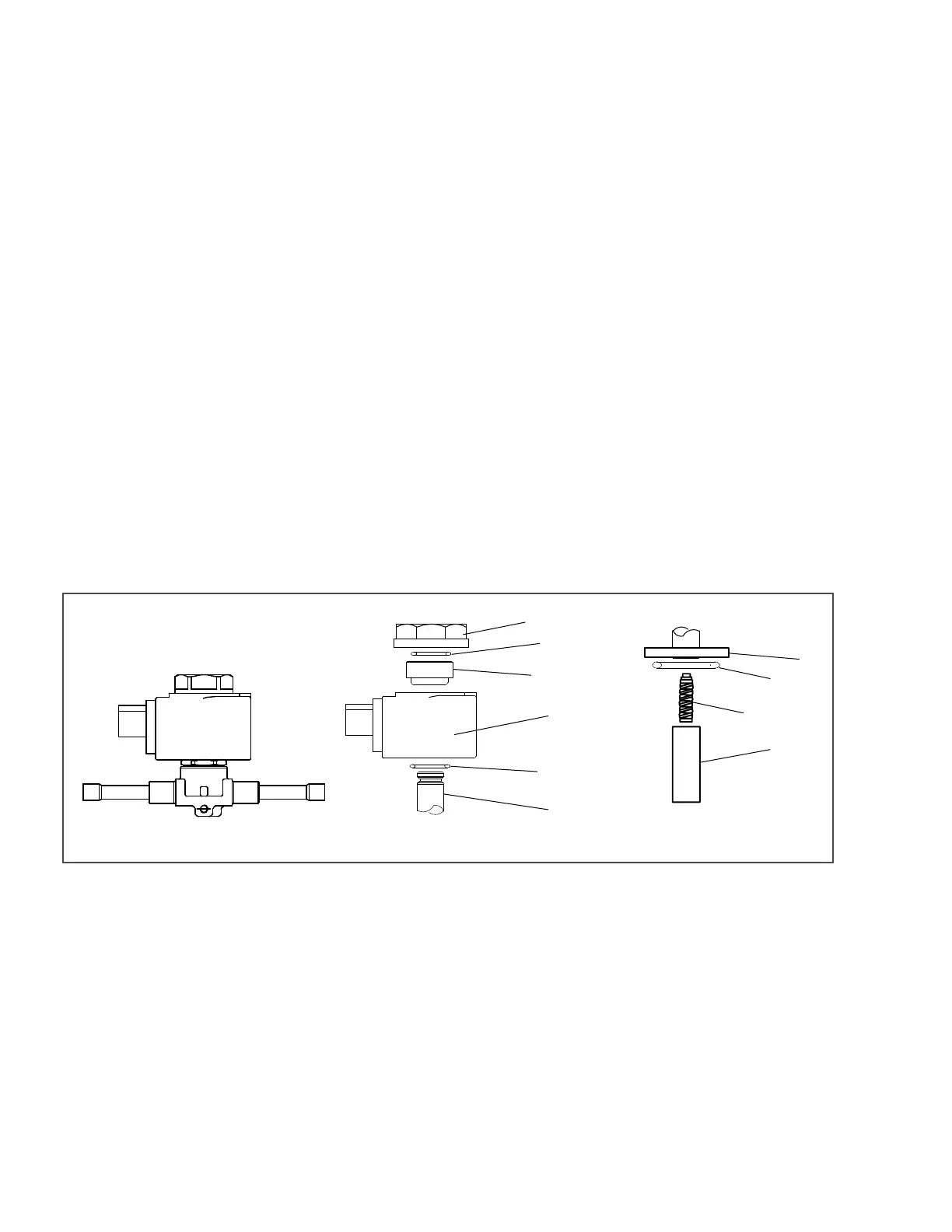

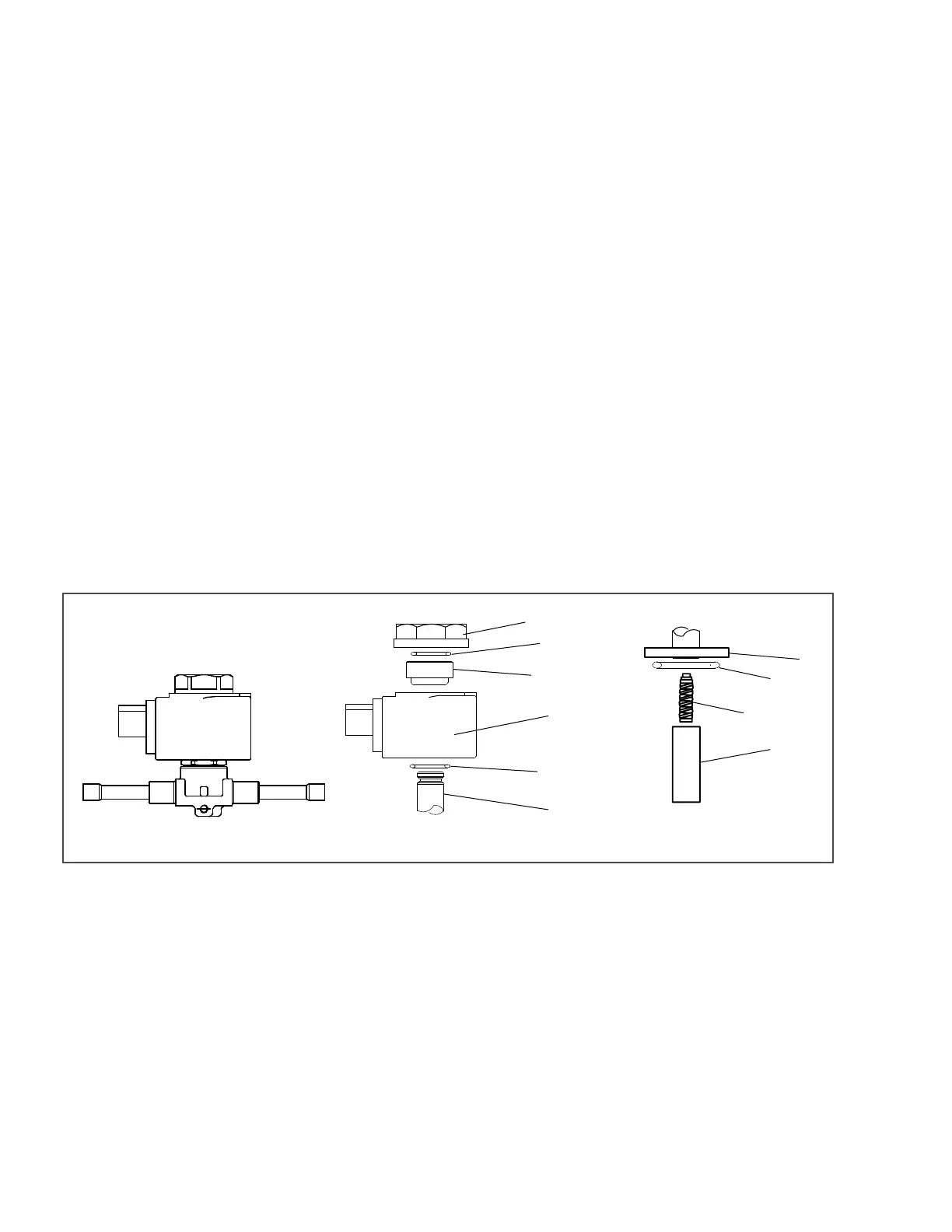

8.8.8 Liquid Injection Solenoid Valve

a. Replacing the Coil:

NOTE

The coil may be replaced without removing

the refrigerant.

1. Ensure the unit will not start automatically by

disabling any two way communication and plac-

ing the STOP/RUN-OFF switch in the OFF posi-

tion. Disconnect the high voltage source and

lockout/tagout the receptacle.

2. Disconnect coil connector.

3. Remove locking nut, upper O−ring, threaded

collar coil and lower O−ring (See Figure 8.26).

4. Verify coil type, voltage and frequency of old

and new coil. This information appears on the

coil housing.

5. Ensure upper and lower O−rings are installed on

top and bottom of coil and tighten locking nut to

1.2 to 1.4 Nm (10 to 18 inch−pounds).

b. Repairing the Valve:

1. Pump down the low side. Refer to Section

8.6.2.

2. Remove the armature tube, taking care the

armature and spring do not drop out.

3. Ensure the spring is properly seated in the

armature and install into the armature tube.

4. Install a new internal O−ring into the valve body

and then reinstall the enclosing tube with arma-

ture and spring.

c. Replacing the Valve:

1. To replace a valve, pump down the low side.

Refer to Section 8.6.2.

2. Ensure the unit will not start automatically by

disabling any two way communication and plac-

ing the STOP/RUN-OFF switch in the OFF posi-

tion. Disconnect the high voltage source and

lockout/tagout the receptacle.

3. Remove coil, refer to “Replacing the Coil”

above.

4. Unbraze valve from unit and braze new valve in

place. Wrap valve in wet rag and point flame

away from valve during brazing operation.

5. Install coil, refer to “Replacing the Coil” above.

Leak check, evacuate the unit and charge in

accordance with Section 8.6.

Figure 8.26 Solenoid Valve

1. Locking Nut

2. Upper O−Ring

3. Threaded Collar

4. Coil

5. Lower O−Ring

6. Armature Tube

7. Internal O−Ring

8. Spring

9. Armature

- - - - -

8.8.9 High Pressure Switch

a. Replacing High Pressure Switch

1. Pump down the compressor (Section 8.6.2).

2. Disconnect wiring from switch, and remove

switch.

3. Install switch after verifying switch settings.

(Refer to following step b.)

4. Leak check, evacuate & dehydrate, and charge

system as required. Refer to Section 8.6.2,

Section 8.6.3 & Section 8.6.4.

COIL ASSEMBLY INTERNAL COMPONENTSLIQUID INJECTION VALVE

1

2

3

4

5

6

6

7

8

9

Loading...

Loading...