8–33 62-11640

8.9 ELECTRICAL SYSTEM COMPONENT SER-

VICE

Procedures for servicing or maintaining the electrical

system components are provided in the following sub-

paragraphs.

NOTE

When any module is replaced, software

should be upgraded before switching the

unit on. This will ensure software compatibil-

ity of all modules.

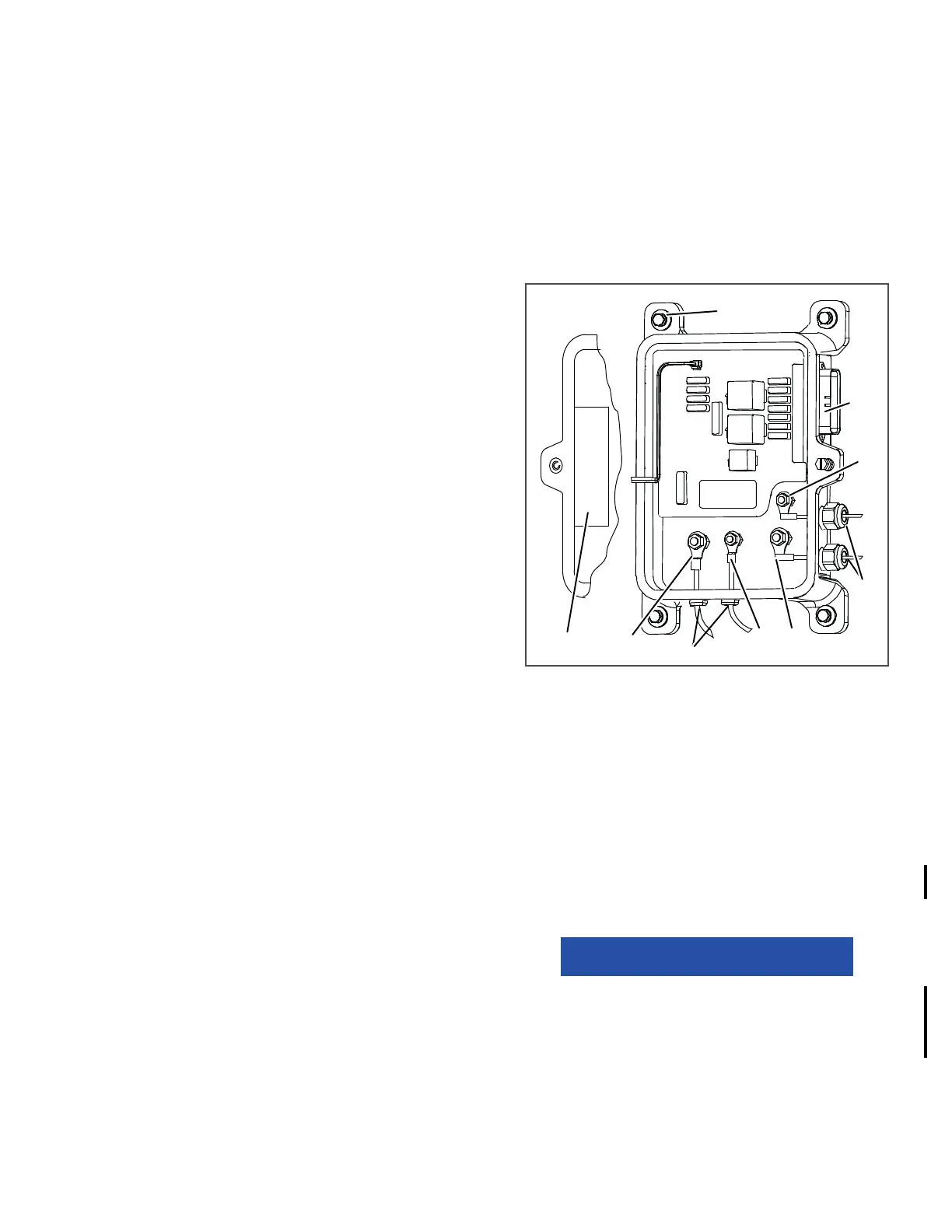

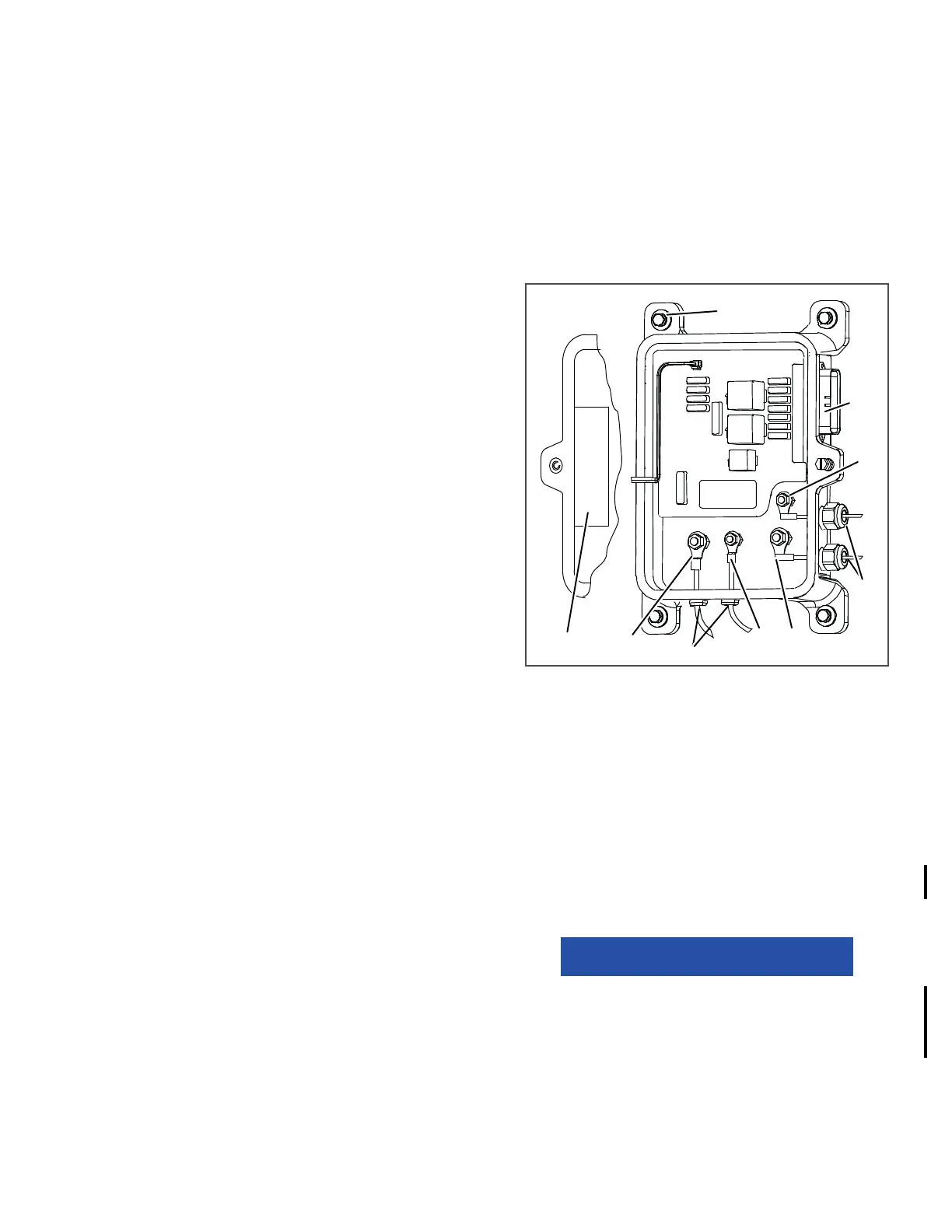

8.9.1 Main Microprocessor Module (MM)

For complete Main Microprocessor Module replace-

ment instructions refer to Section 5.5.2

8.9.2 Power Control Module (PCM)

NOTE

The buzzer, buzzer harness, fuses, door, door

seal, hinge pin, door screw (with retainer) and

relays may be purchased separately and do

not require complete module replacement.

1. Disconnect main power leads at battery.

2. Open Power Control module door. Loosen &

remove stud-post terminal nuts (brass) at termi-

nals BAT+ (6, Figure 8.29); BAT– (7); ALT+ (5)

& EPH (3).

3. Remove nuts holding plastic bushings (4) &

leave hanging on wire.

4. Lift the 4 cable terminals up & off stud-posts.

Remove loose nuts, slide plastic bushings &

cables/terminals out of mounting hole in box.

5. Unlock tab on 35 pin connector (2) & remove

connector.

6. Remove the four fasteners (1) mounting Power

Control module to unit frame & remove module

from unit

7. Follow steps above in reverse order to install

new Power Control Module. Torque:

• fasteners mounting module to frame (1) to 38

to 58 inch/lbs (4.3 to 6.6 Nm)

• M6 terminal nuts (3 & 7) to 30 to 40 inch/lbs

(3.4 to 4.5 Nm)

• M8 terminal nuts (5 & 6) to 60 to 80 inch/lbs

(6.8 to 9.0 Nm). See Figure 2.5.

8. Note a component legend sticker is to be

located inside the PCM door. Install the correct

sticker (packaged with the replacement PCM)

for this unit inside the replacement PCM. The

replacement PCM is populated at the factory

with the standard fuses and relays. Additional

fuses and relays may be required for this appli-

cation (refer to Figure 2.5) transfer the required

fuses and relays from the original PCM to the

replacement PCM as required.

Figure 8.29 Power Control Module

1. Mounting Fasteners

2. 35 Pin Connector

3. Engine Preheat Terminal (EPH)

4. Plastic Bushings

5. Alternator Positive Terminal (ALT +)

6. Battery Negative Terminal (BAT-)

7. Battery Positive Terminal (BAT +)

8. Door Mounted Legend Sticker

- - - - -

9. Make sure the latest software has been loaded

to ensure all modules are compatible, refer to

Section 5.3.4.

NOTICE

When a module is replaced, software

should be upgraded before switching the

unit on. This will ensure software com-

patibility of all modules.

10. Start unit and run Pretrip to check operation.

1

2

3

4

5

6

4

7

8

Change 09/14

Loading...

Loading...