Figure 233

The engine oil is highly polluting and harmful.

In case of contact with the skin, rinse well with water

and detergent.

Adequately protect the skin and the eyes, operate in

full compliance with safety regulations.

Disposal must be carried out properly, and in full com-

pliance with the law and regulations in force.

Figure 234

!

75749

Checks not included in maintenance planning−daily checks

It is a good habit to execute, before engine start, a series of simple checks that might represent a valid warranty to avoid inconven-

iences, even serious, during engine running. Such checks are usually up to the operators and to the vehicle’s drivers.

− Level controls and checks of any eventual leakage from the fuel, cooling and lubricating circuits.

− Notify the maintenance if any inconvenience is detected of if any filling is necessary.

After engine start and while engine is running, proceed with the following checks and controls:

− check presence of any eventual leakage from the fuel, cooling and lubricating circuits.

− Verify absence of noise or unusual rattle during engine working.

− Verify, using the vehicle devices, the prescribed pressure temperature and other parameters.

− Visual check of fumes (colour of exhaust emissions)

− Visual check of cooling liquid level, in the expansion tank.

MAINTENANCE PROCEDURES − CHECKS

AND CONTROLS

Engine oil level check.

The check must be executed when the engine is disconnected

and possibly cool.

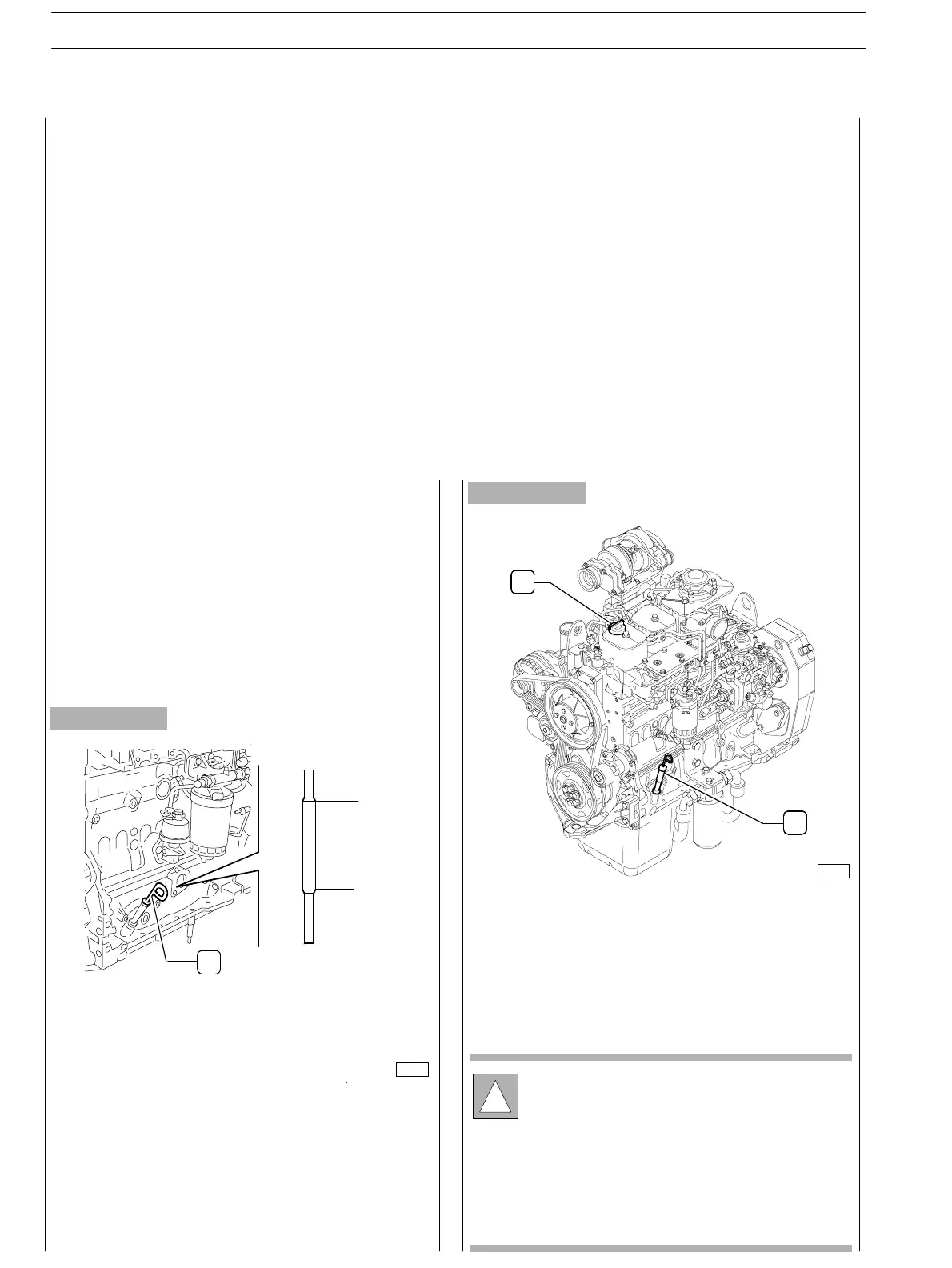

Thecheckcanbemadeusingthespeciallyprovidedflexiblerod

(1).

Draw off the rod from its slot and check that the level is within

the etched tags of minimum and maximum level.

Whether it should be difficult to make the evaluation, proceed

cleaning the rod using a clean cloth with no rag grinding and put

it back in its slot. Draw it off again and check the level.

In case the level results being close to the tag showing minimum

level, provide filling lubrication of the engine’s components.

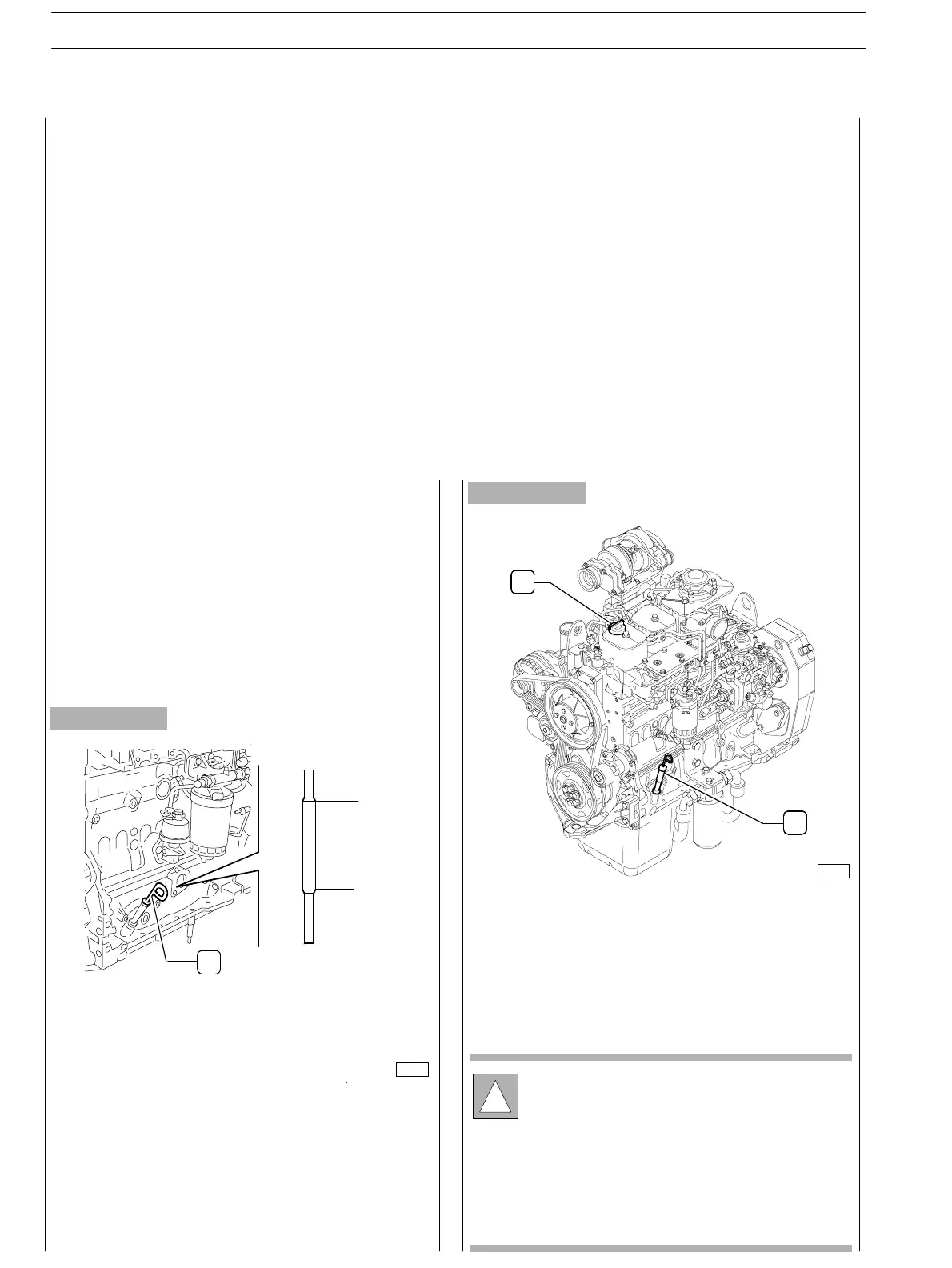

To provide filling, oper ate through the upper top (1)orthrough

the lateral top (2). During filling operation, the tops must be re-

moved as well as the rod in order to make the oil flow easier”.

Some applications are equipped with a level transmitter alerting

dashboard instruments in case of insufficient lubrication oil

within the pan.

75748

1

MAX

MIN

1

2

SECTION 3 − DUTY − INDUSTRIAL APPLIC ATION

94

ENGINES

ED. FEBUARY 2003

Loading...

Loading...