70194

70195

70196

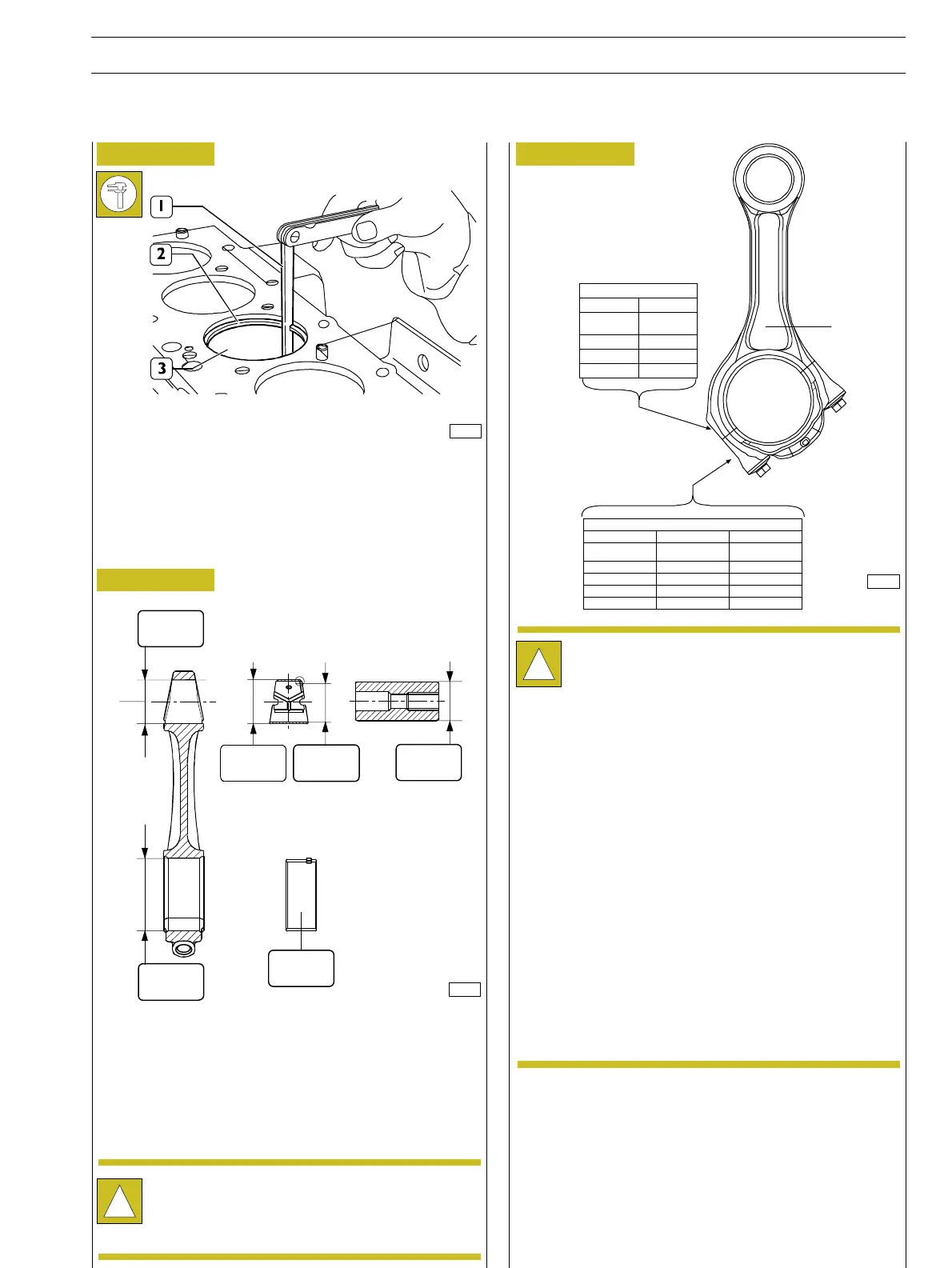

Figure 50

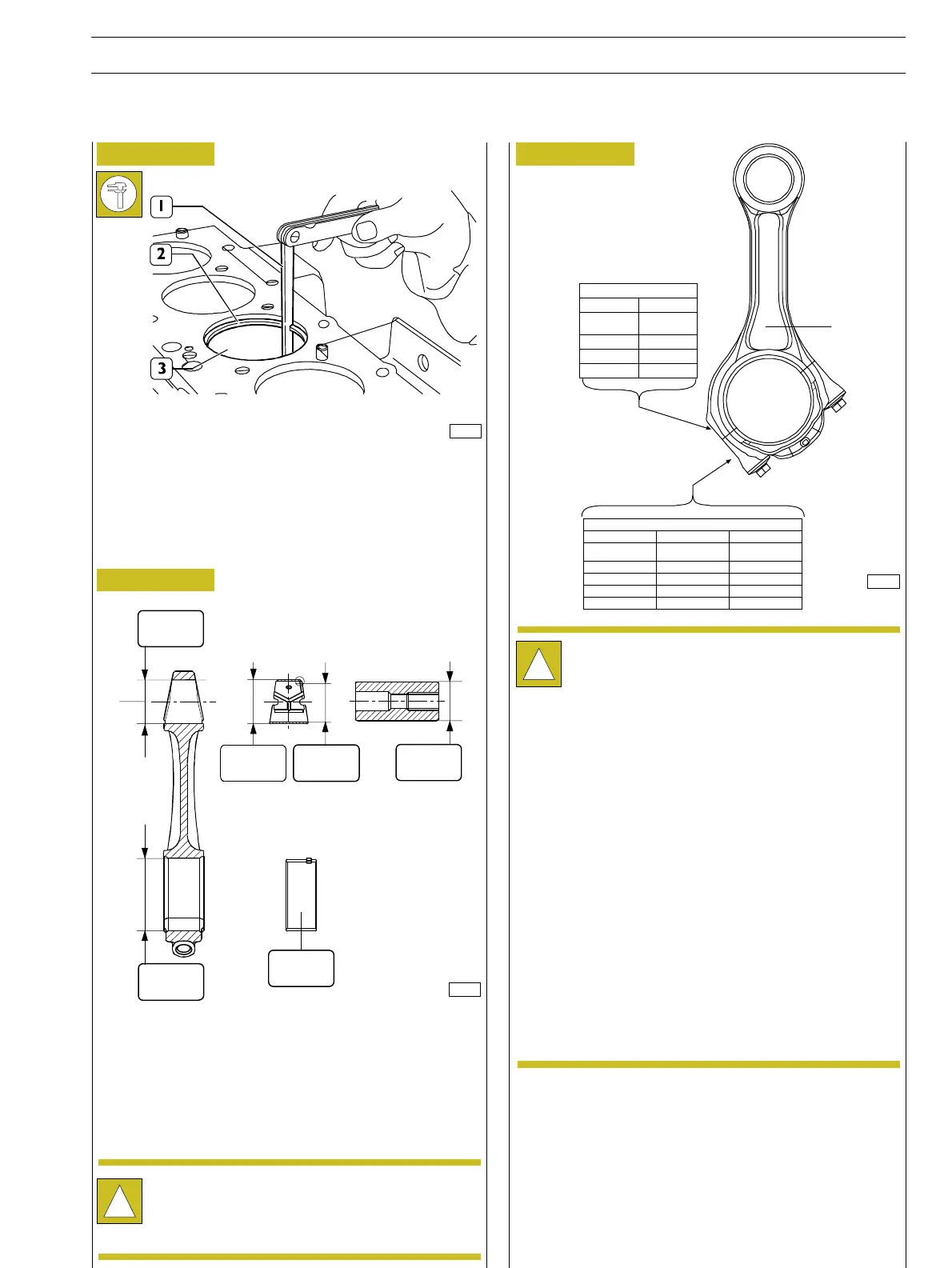

Figure 51

Figure 52

Use feeler gauge (1) to measure the clearance between the

ends of the split rings (2) fitted into the cylinder barrel (3).

MAIN DATA FOR CONNECTING ROD, BUSH,

PISTON PIN AND HALF BEARINGS

* Value for inside diameter to be obtained after driving in

connecting rod small end and grinding.

** Value not measurable in released condition

Bushes

Check that the bush in the connecting rod small end is free

from scoring or seizing and that it is not loosen. Otherwise

replace.

Removal and refitting shall be performed using the proper

beater.

When refitting take care to make coincide the oil holes set

on the bush with those set on the connecting rod small end.

Grind the bush to obtain the specified diameter.

Connecting rods

!

Every connecting rod is marked as follows:

On body and cap with a number showing their

coupling and the corresponding cylinder.

In case of replacement it is therefore necessary

to mark the new connecting rod with the same

numbers of the replaced one.

On body with a letter showing the weight of the

connecting rod assembled at production:

V, 1820 to 1860 (yellow marking);

W, 1861 to 1900 (green marking);

X, 1901 to 1940 (blue marking);

Spare connecting rods are of the W class with green

marking *.

Material removal is not allowed.

*

*

*

*

*

*

!

The surface of connecting rod and rod cap are

knurled to ensure better coupling.

Therefore, it is recommended not to smooth the

knurls.

SECTION 4 – OVERHAUL AND TECHNICAL SPECIFICATION

ENGINES

25

ED. FEBRUARY 2003

CONNECTING ROD BODY

1234 W

CONNECTING

ROD No.

WEIGHT

0001 V

W

9999 X

CONNECTING ROD CAP

1234 A 123

CONNECTING

ROD No.

YEAR DAY

0001 A 1998 001

B 1999

9999 C 2000 366

D 2001

40.987

41.013

40.987

41.013

38.019

38.033

38.000

38.006

1.955

1.968

72.987

73.013

Loading...

Loading...