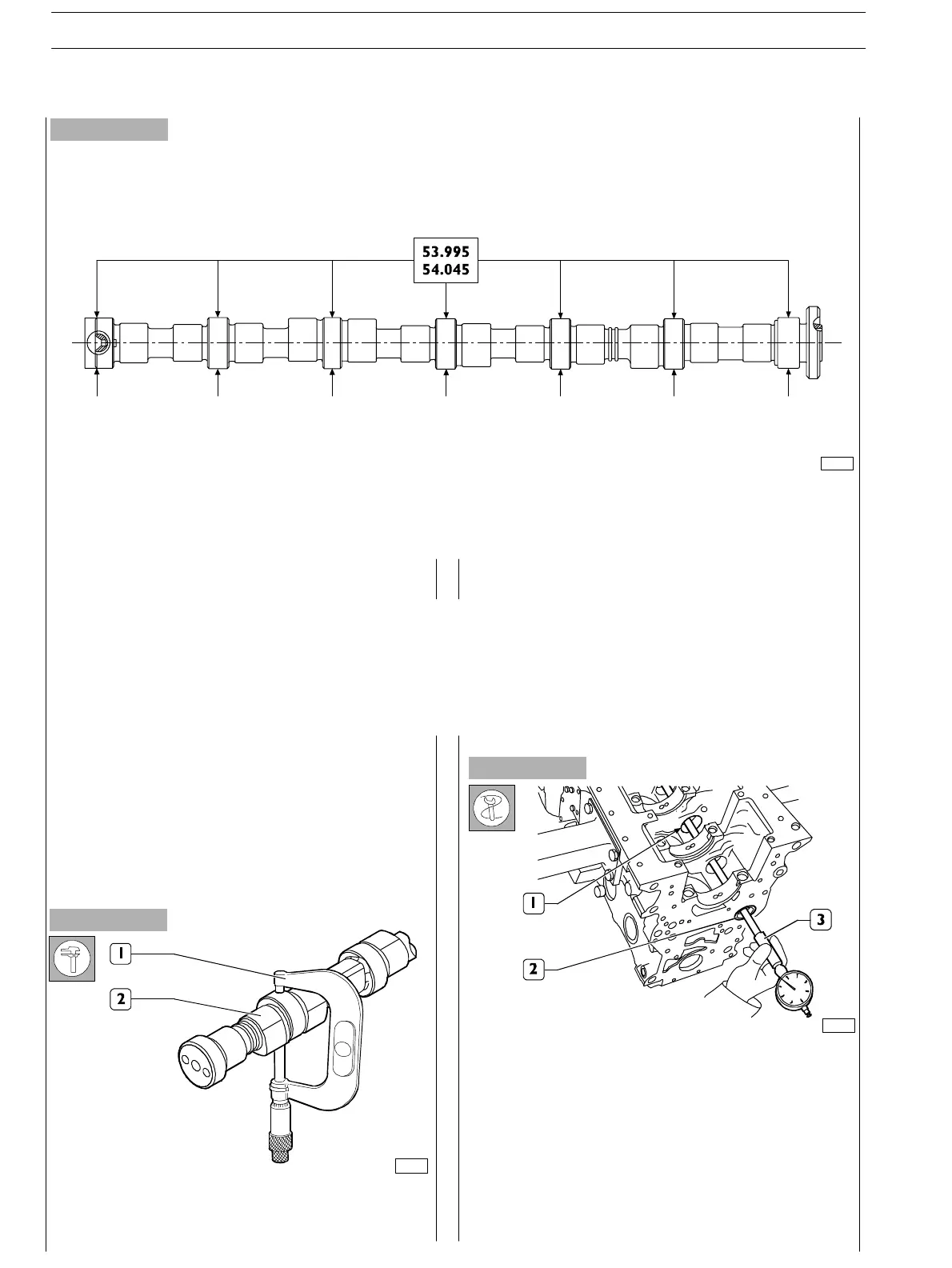

70512

Figure 13

MAIN DATA ABOUT CAMS HAFT PINS (6 CYL.)

Camshaft pin and cam surfaces shall be absolutely smooth;

if they show any traces of seizing or scoring replace the

camshaft and the bushes.

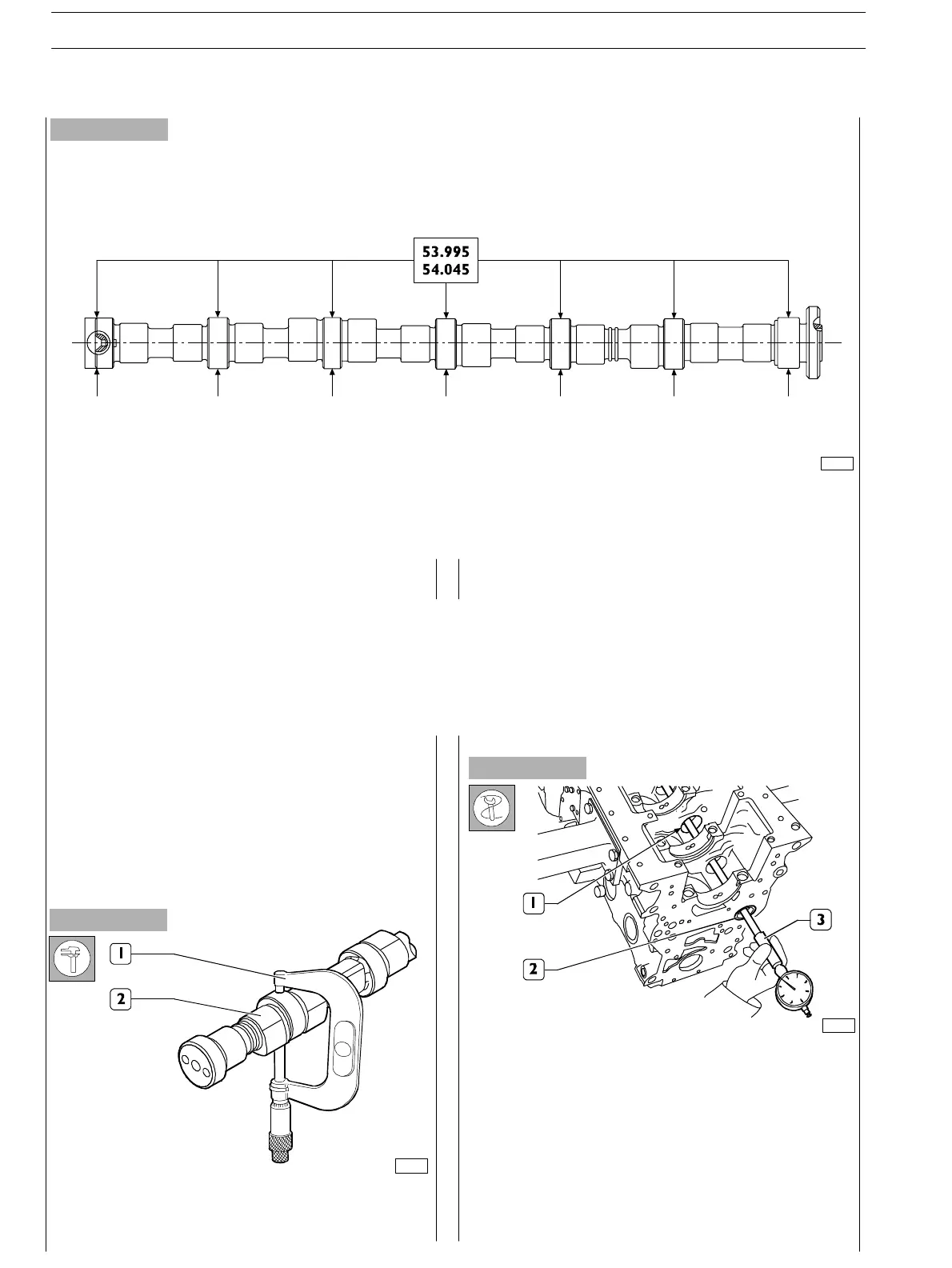

70171

70172

Figure 14

Figure 15

Check camshaft (2) pin diameter using micrometer (1) on

two perpendicular axes.

Camshaft bushes (2) shall be pressed into their housings.

Internal surfaces must not show seizing or wear.

Use bore dial gauge (3) to measure camshaft front and rear

bush (2) and intermediate housing (1) diameter.

Measurements shall be performed on two perpendicular

axes.

BUSHESChecking cam lift and pin alignment

Set the camshaft on the tailstock and usin g a 1/100 gauge set

on the central support, check whether the alignment error

is not exceeding 0.04 mm, otherwise replace the camshaft.

Check cam lift; found values shall be: 6.045 mm for exhaust

cams and 7.582 mm for intake cams, in case of different values

replace the camshaft.

SECTION 4 − OVERHAUL AND TECHNICAL SPECIFICATIONS

14

E NG I NE S

ED. FEBUARY 2003

Loading...

Loading...