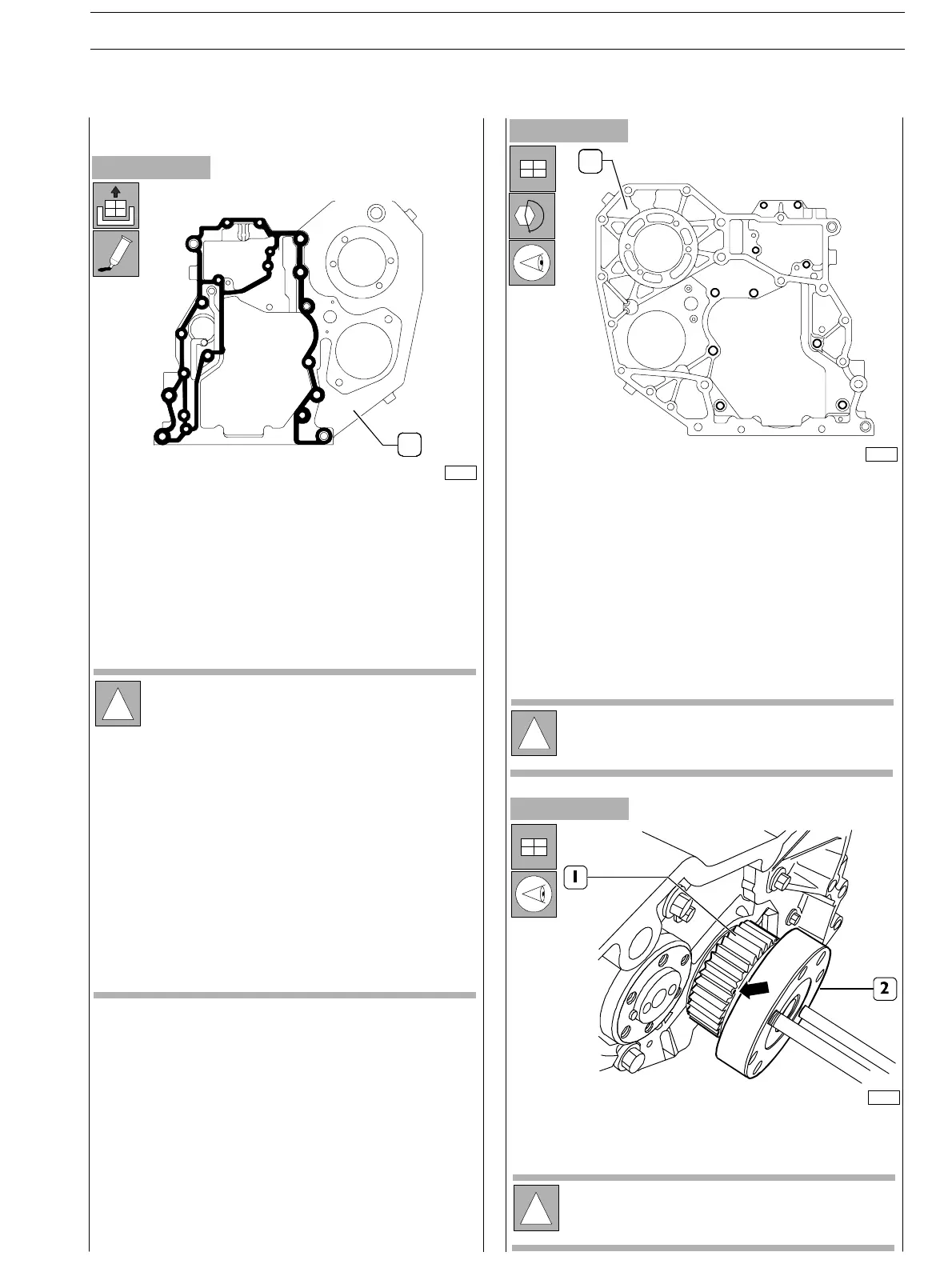

Figure 143

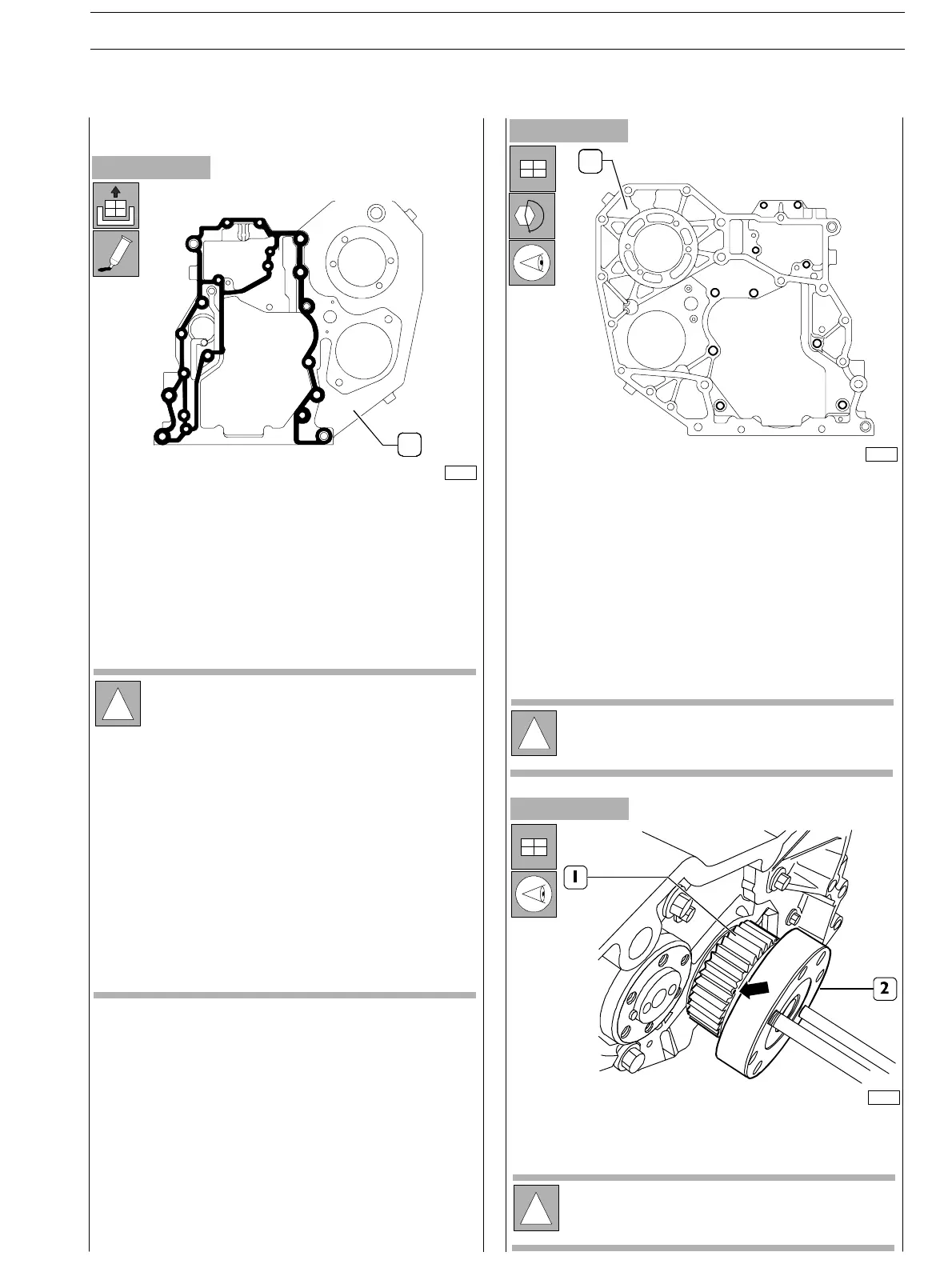

Figure 144

- Reassemble to box (1) to the engine block.

- Tighten the fixing screws in the same position as found

out during disassembly and fix th e screws to th e locking

couples listed here below, following the order as shown

in the picture.

Screws M12 65 ÷ 89 Nm

Screws M8 20 ÷ 28 Nm

Screws M10 42 ÷ 52 Nm

!

It is necessary an d essential to clean the surface to

be sealed in order to achieve excellent tight seal.

Apply sealing LOCTITE 5205 on the box in order to

form a kerbstone of a few mm. Diameter.

It must be u n iform (n o crumbs), with no air blisters,

thinner or irregular zones.

Any eventual imperfection shall be cor rect as soon

as possible.

Avoid using material in excess to seal the joint. Too

mu ch sealing material would drop out on both sides

of the joint and obstr uct lubricant passages.

After having completed seal application, the joints

must be immediately assembled (10−20 minutes

time).

!

Before assembly, always check that the threads of the

ports and of the screws have no evidence of tear and

wear nor dirt.

Installation of application components

1

75712

DIAGRAM SHOWING SEALING LOCTITE 5205

APPLICATION WITHIN GEARBOX AREAS

- Accurately clean t he timing gearbox (1) and the en gine

block.

75711

1

2

3

4

5

6

7

8

910

1

DIAGRAM SHOWING SCREW

TIGHTENING TO FIX REAR GEARBOX

Figure 145

70211

- With a pen marker, mark t he tooth (1) of the driving gear

assembled to the engine drive shaft with (2) (→) timing

notch.

!

Screw u p two pins to facilitate operation of engine

drive shaft rotation.

SECTION 3 − DUTY − INDUSTRIAL APPLICATION E NG I NE S

49

ED. FEBUARY 2003

Loading...

Loading...