32620

16552

32619

18857

41104

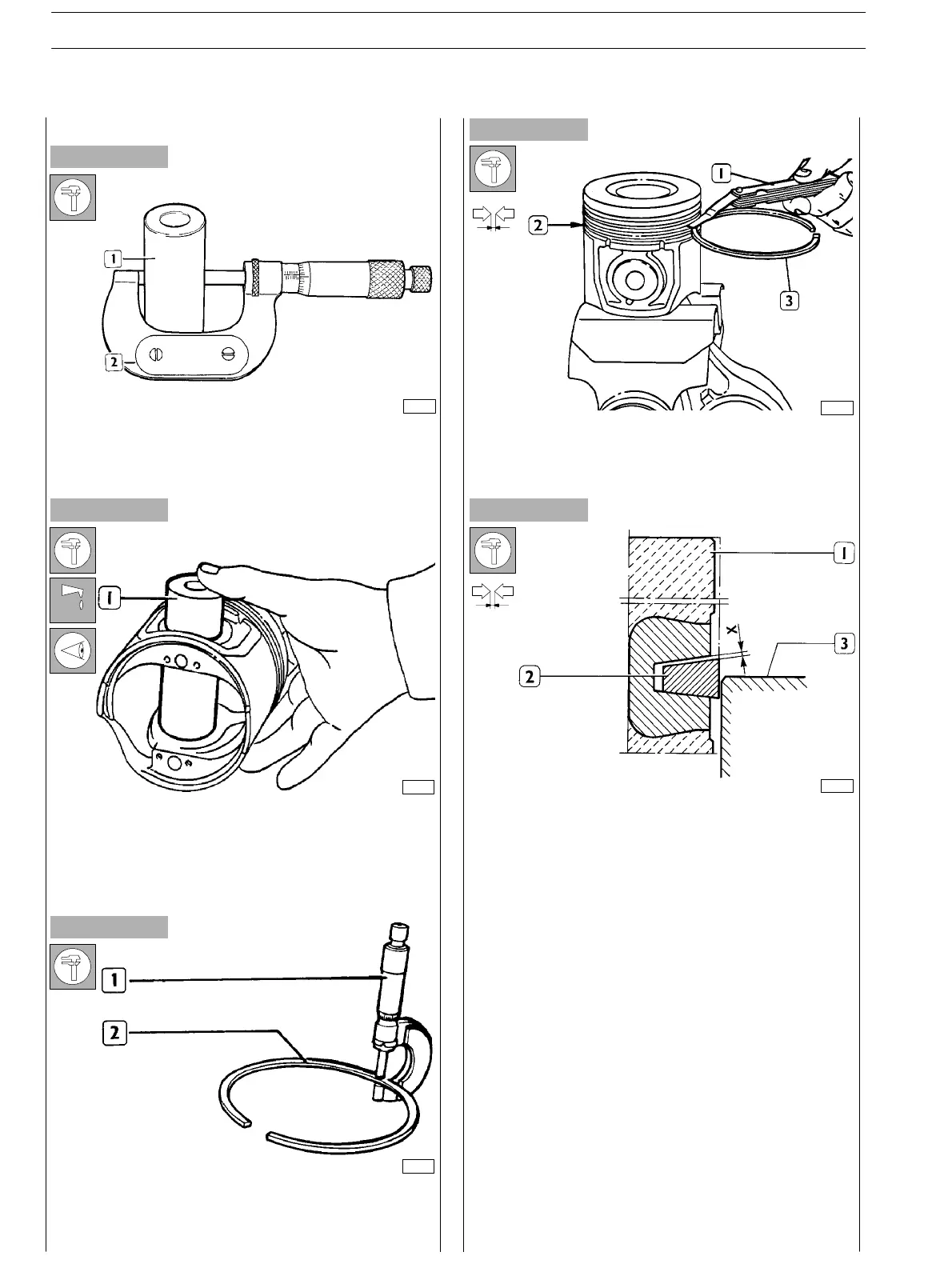

Figure 45

Figure 46

Figure 47

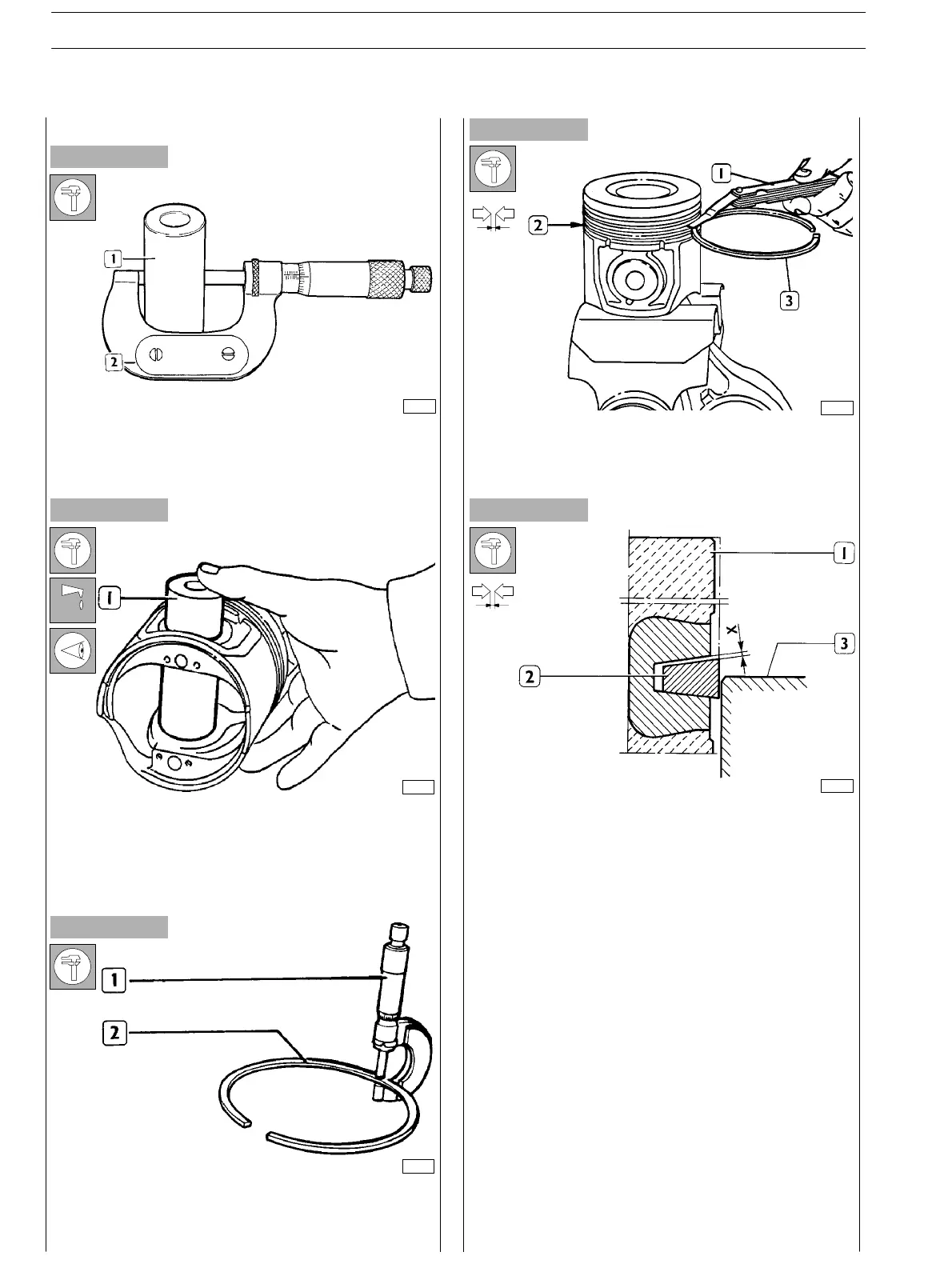

Figure 48

Figure 49

To measure the piston pin (1) diameter use the micrometer

(2).

Conditions for proper pin−piston coupling

Lubricate the pin (1) and its seat on piston hubs with engine

oil; the pin shall be fitted into the piston with a slight finger

pressure and shall not be withdrawn by gravity.

Use a micrometer (1) to check split ring (2) thickness.

Check the clearance between the sealing rings (3) of the 2

nd

and 3

rd

slot and the relevant housings on the piston (2), using

a feeler gauge (1).

DIAGRAM FOR MEASURING THE CLEARANCE X

BETWEEN THE FIRST PISTON SLOT AND THE

TRAPEZOIDAL RING

Since the fir st sealing ring section is trapezoidal, the clearance

between the slot and th e r in g shall be measured as follows:

make the piston (1) protrude from the engine block so that

the ring (2) protrudes half−way from the c ylinder barrel (3).

In this position, use a feeler gauge to check the clearance (X)

between ring and slot: found value shall be the specified one .

Piston pins

Split rings

SECTION 4 − OVERHAUL AND TECHNICAL SPECIFICATIONS

24

E NG I NE S

ED. FEBUARY 2003

Loading...

Loading...