70163

70165

70164

70166

70167

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

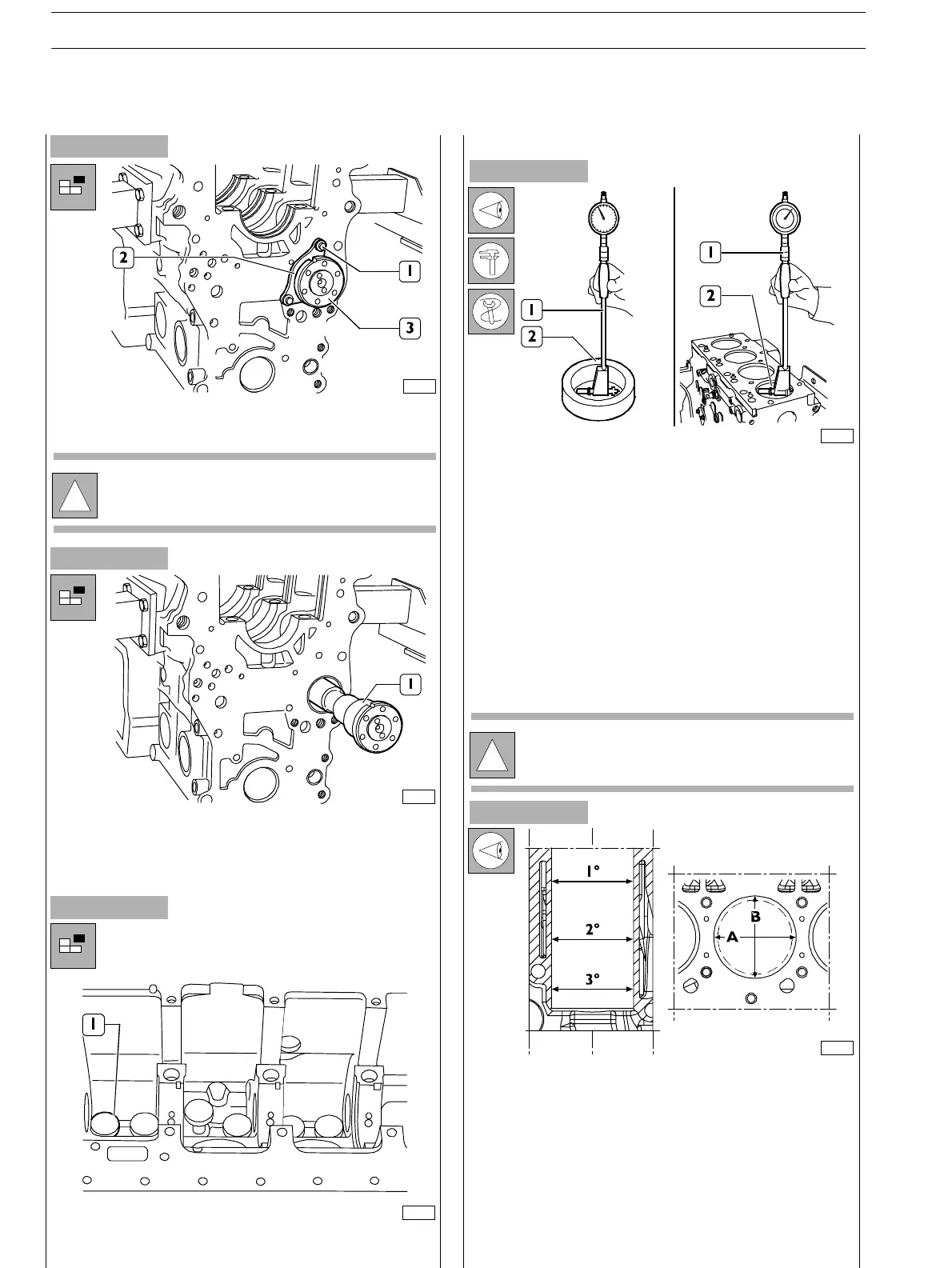

Remove the screws (1) and disconnect camshaft (3) retaining

plate (2).

Withdraw carefully the camshaft (1) from the en gin e block.

Withdr aw the tappets (1) from the engine block.

Once engine is disassembled, clean accurately the

cylin der−bloc k assembly.

Use the proper rings to handle the cylinder unit.

The engine block shall not show c racks.

Check operating plug conditions and replace them in case of

uncertain seal or if rusted.

Inspect cylinder barrel su rfaces; th ey shall be free from seizin g,

scores, ovalisation, taper or excessive wear.

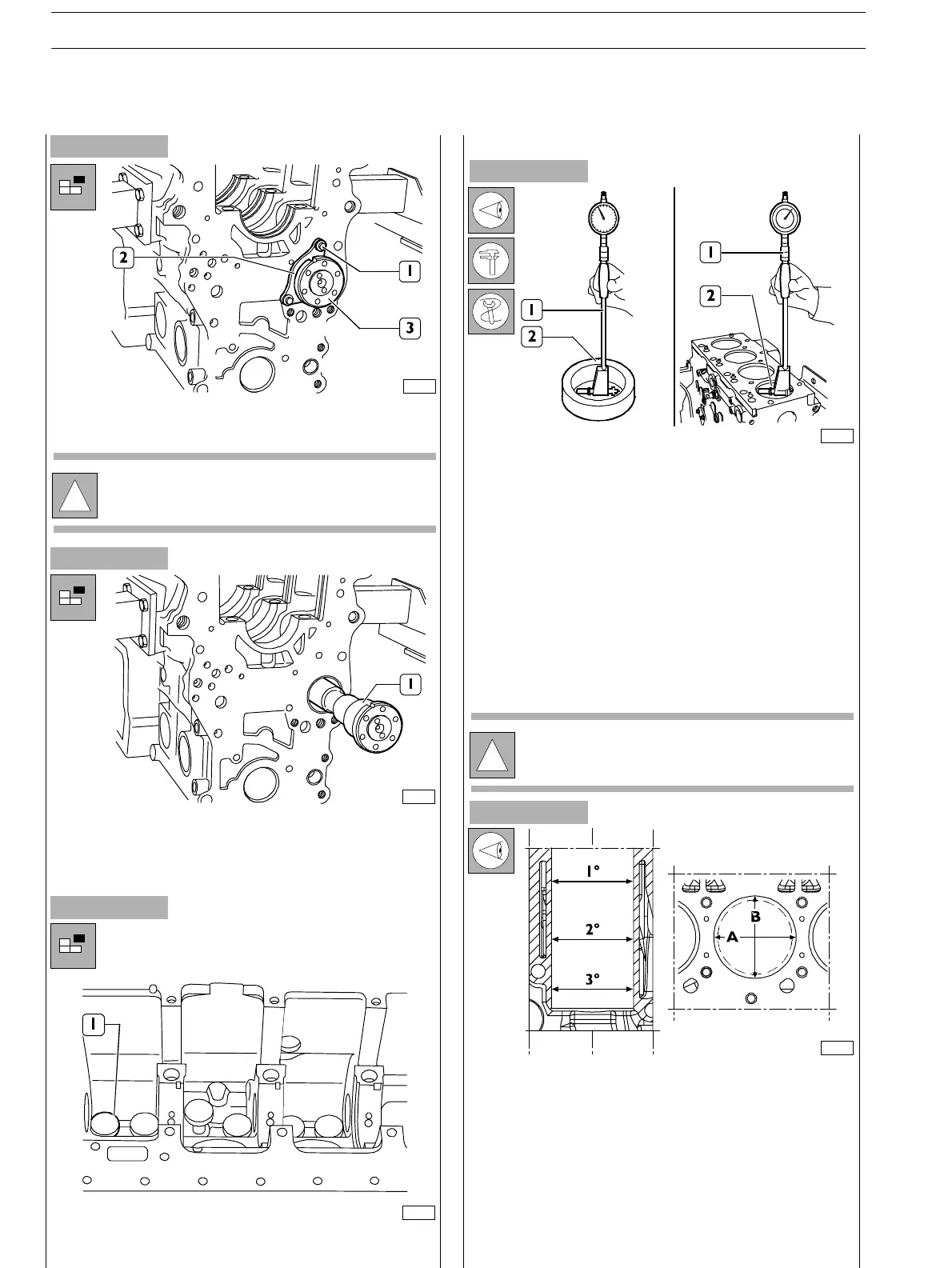

Inspection of cylinder barrel bore to check ovalisation, taper

and wear shall be performed using a bore dial gauge

(I) fitted with the dial gauge previously set to zero

on the ring gauge (2) of t he cylinder barrel diameter.

Measurements shall be performed on each cylinder, at three

different heights in the barrel and on two planes

perpendicular with each other: on e parallel to t h e

longitudinal axis of the engine (A), and the oth er

perpendicular (B). Maximum wear is usually found on plane

(B) in correspondence with the first measurement.

Should ovalisation, taper or wear be found, bore an d grind

the cylinder barrels. Cylinder barrel regrinding sh all be

performed according to the spare piston diameter oversized

by 0.5 mm and to the specified assembling clearance.

!

Take note of plate (2) assembling position.

REPAIR OPERATIONS

CYLINDER UNIT

Checks and measurements

!

Should the r ing gauge be n o t available, use a

micrometer for zero−setting.

s

SECTION 4 − OVERHAUL AND TECHNICAL SPECIFICATIONS

12

E NG I NE S

ED. FEBUARY 2003

zs

Loading...

Loading...