70184

70185

70187

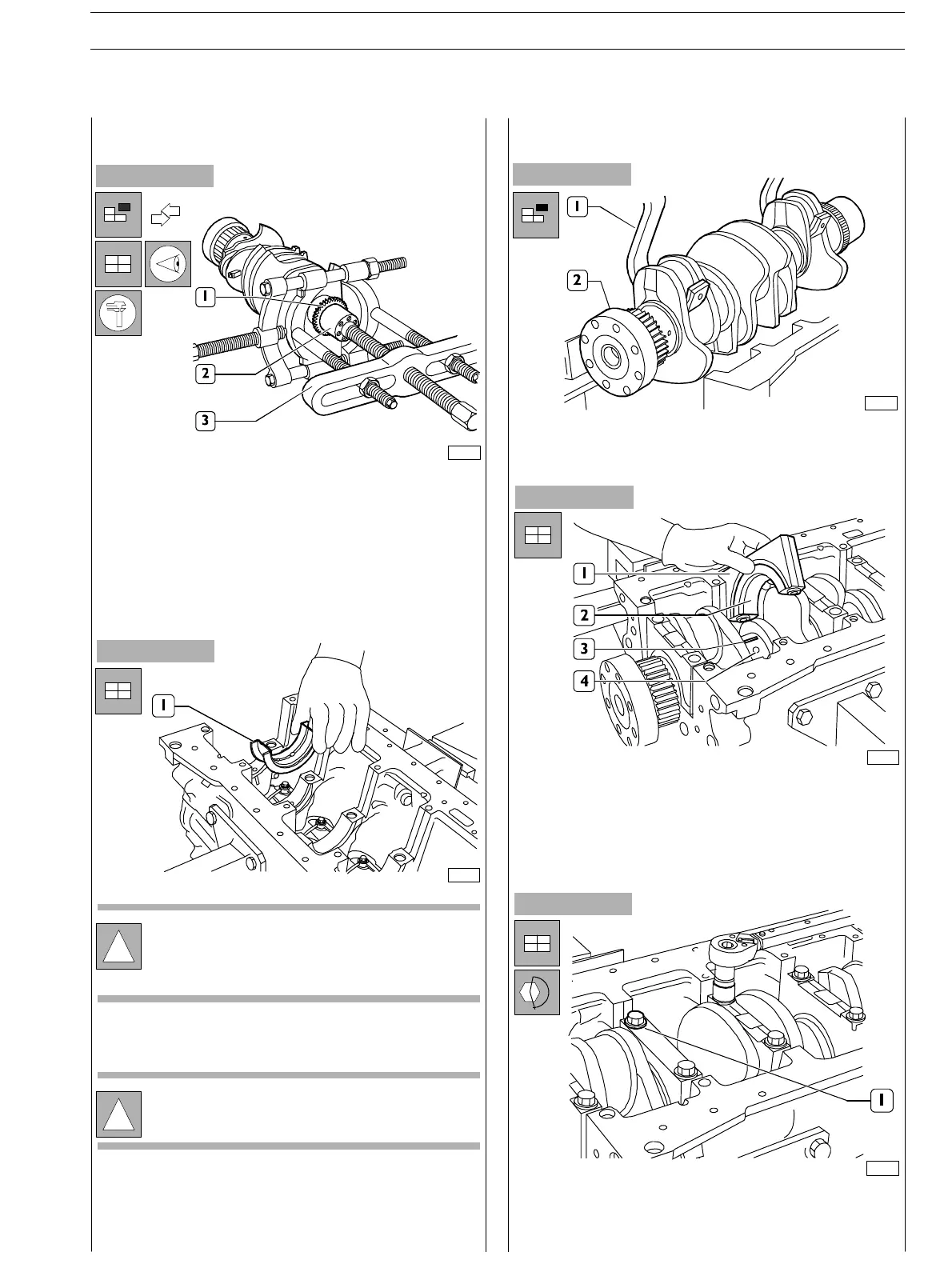

Figure 31

Figure 32

Figure 33

Figure 34

Refit the output shaft (2).

Check the backlash between output shaft main journals and

the relevant bearings as follows:

Tighten the pre−lubric ated screws (1) in the following three

succ essive stages:

- 1

st

stage , with dynamometric wrench to 50 ± 6 Nm.

- 2

nd

stage , with dynamometric wrench to 80 ± 6 Nm.

!

Refit the main bearings that have not been replaced,

in the same position fou nd at removal.

Fitting main bearings

!

Do not try to adapt the bearings.

Main bearings (1) are supplied spare with 0.250 — 0.500 mm

undersize on the internal diameter.

Clean accurat ely the main half bearings (1) having the

lubricating hole and fit them into their housings.

The second last main half bearing (1) is fitted w ith shoulder

half rings.

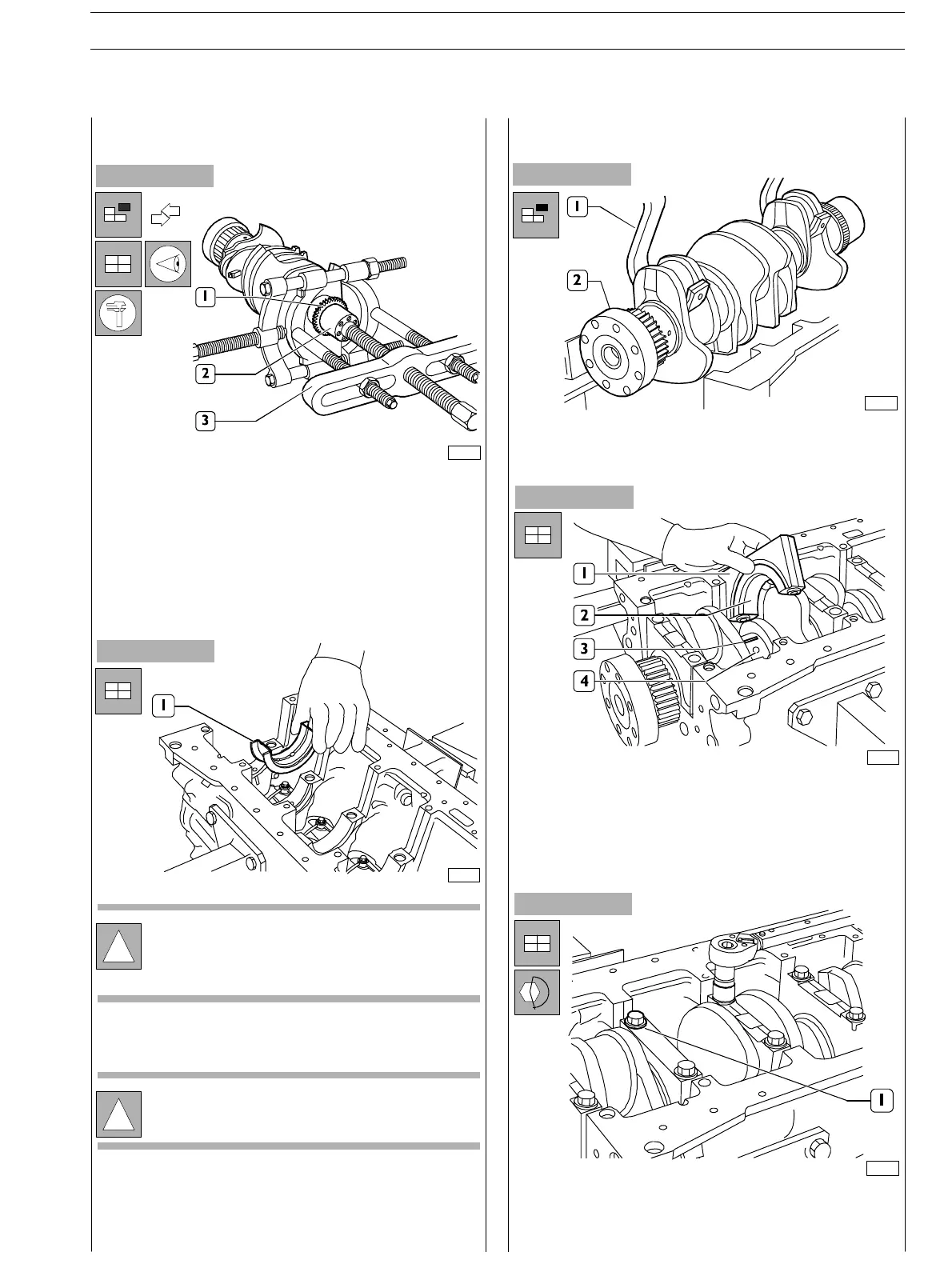

Check that gear toothing (1) is not damaged or worn,

otherwiseremoveitusingtheproperpuller(3).

When fitting the new gear, heat it to 180°C for 10 minutes

in an oven and then key it to the output shaft.

Finding journal clearance

Figure 35

- clean accurately the parts and remove any trace of oil;

- position a piece of c alibrated wire (3) on the ou t put sh aft

pins (4) so that it is parallel to the longitu dinal axis;

- fit caps (1), including t he half bearings (2) on the relevan t

supports.

70186

70161

Replacing oil pump control gear

SECTION 4 − OVERHAUL AND TECHNICAL SPECIFICATIONS E NG I NE S

21

ED. FEBUARY 2003

Loading...

Loading...