Check of drive belt tensioning

75806

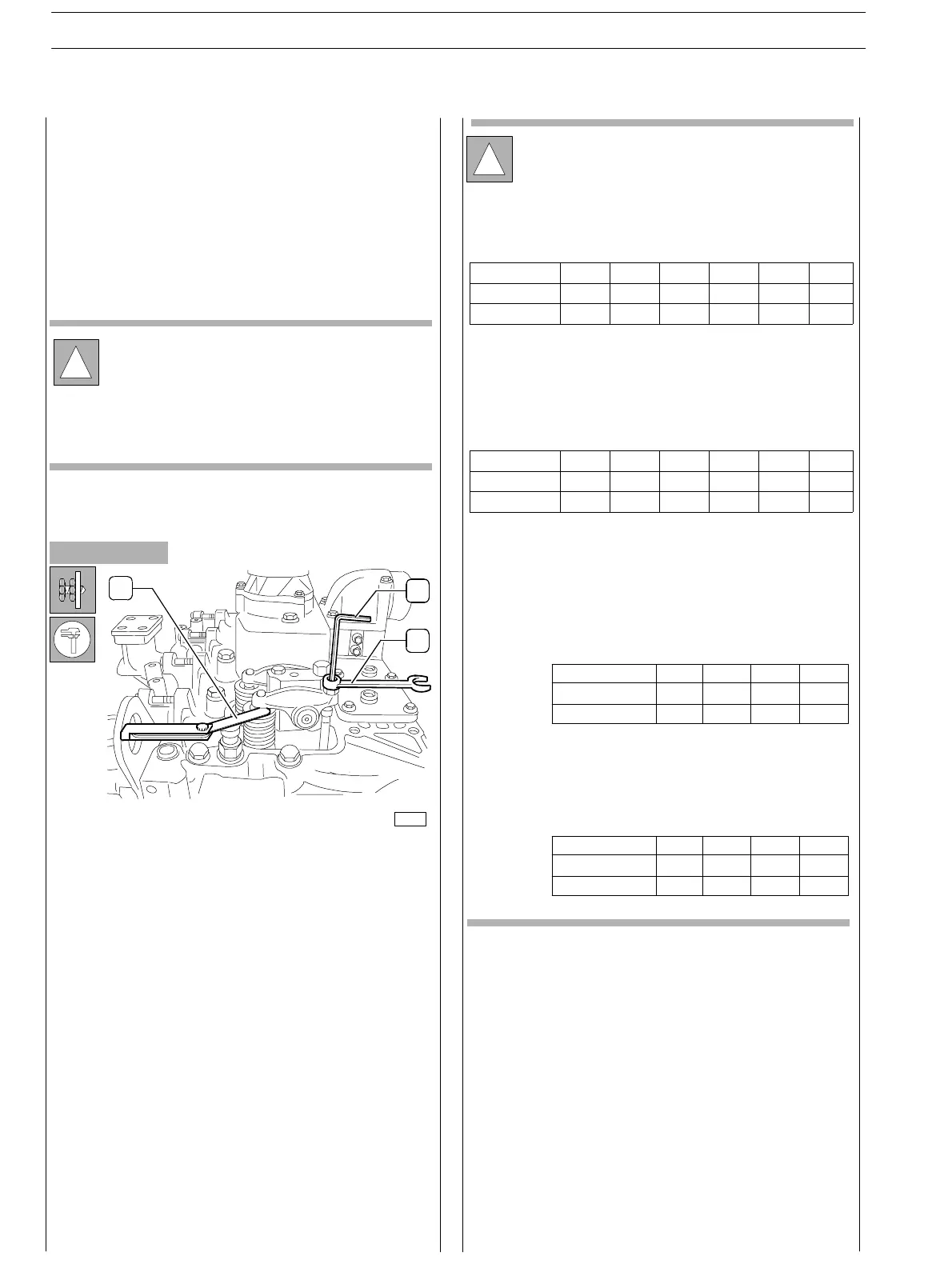

Adjust clear ance between rockers and valves using setscrew

wrench (1), box wrench (3) and feeler gauge (2).

Working clearance shall be as follows:

− intake valves 0.30 ± 0.05 mm

− exhaust valves 0.55 ± 0.05 mm.

!

In order to more quickly perform the operating clear-

ance adjustment for rocker arms — valves, proceed as

follows:

rotate the drive shaft, balance cylinder 1 valves and

adjust the valves marked by the asterisk as shown in

the table:

Rotate the drive shaft of 360 deg., balance cylinder 6

valves and adjust the valves marked by the asterisk as

showninthetable:

Engine with 4 cylinder: rotate the drive shaft, balance

cylinder 1 valves and adjust the valves marked b y the

asterisk as shown in the table:

Rotate the drive shaft of 360 deg., balance cylinder 4

valves and adjust the valves marked by the asterisk as

showninthetable:

cylinder n.

intake

exhaust

1

234

−

*

**

*

−

−−

cylinder n.

intake

exhaust

1

234

−

*

**

*

−

−

−

Check and setting of tappet clearance

Figure 235

2

1

3

Some applications are equipped with an automatic tensioner

that provides correcting belt tensioning.

Check of belt’s tear and wear status

Carefully verify the belt’s surface in order to detect any sign of

incision, crack, excessive wear in cor r espondence of toothing;

check end and surface grinding.

!

Danger: if the engine is switched off but is still hot, un-

expected motion of the belt may occur.

Wait for engine temperature cooling as a precaution

in order to avoid serious danger injury.

SECTION 3 − DUTY − INDUSTRIAL APPLIC ATION

96

ENGINES

ED. FEBUARY 2003

cylinder n. 1 2 3 4 5 6

intake * * − * − −

exhaust * − * − * −

cylinder n. 1 2 3 4 5 6

intake − − * − * *

exhaust − * − * − *

Loading...

Loading...