Fuel filter replacement

75684

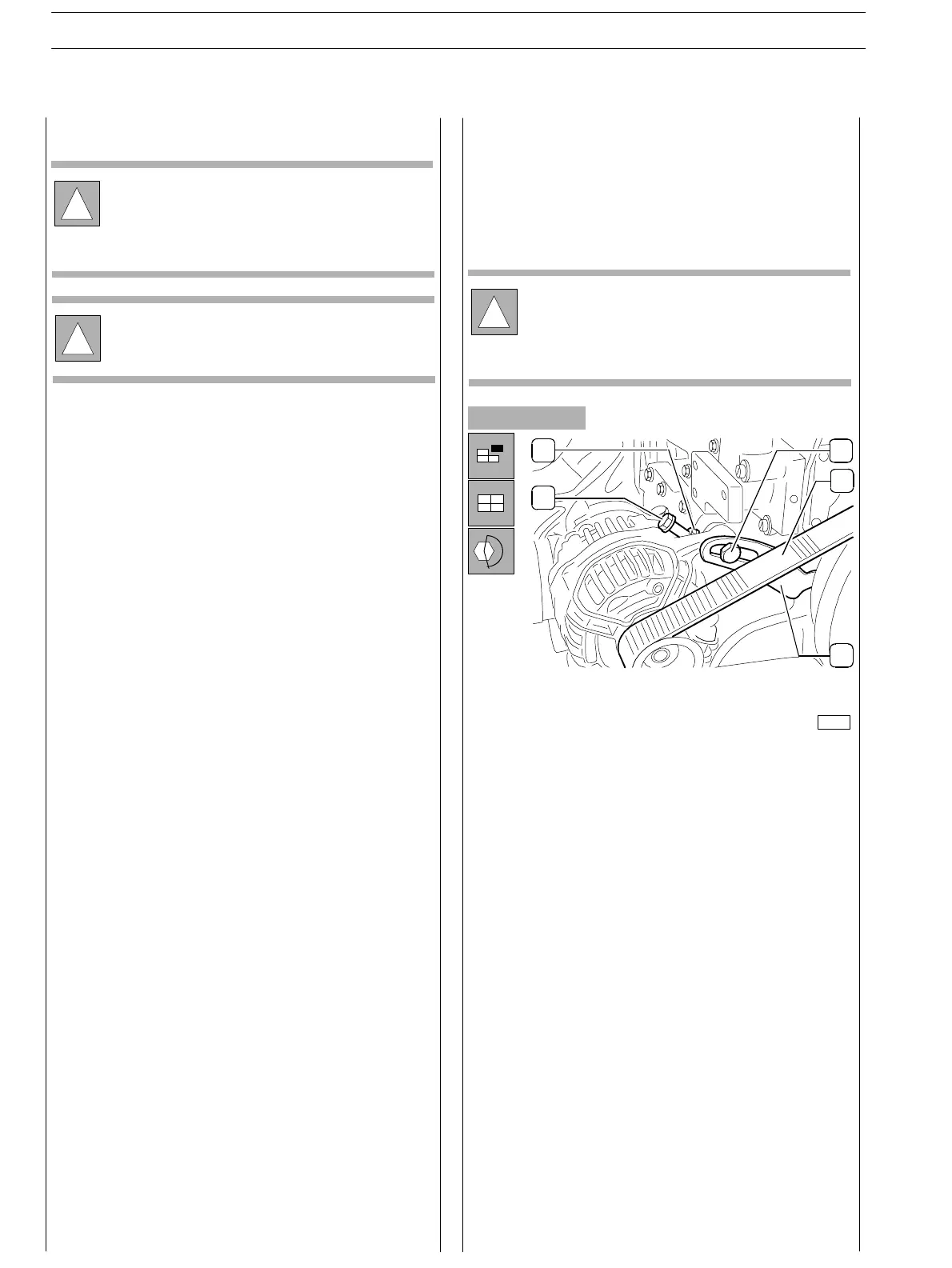

- Unloosethescrew(1) on the tension staff of the alterna-

tor belt by unloosing the lock nut (2). Unscrew the screw

(3) in order to unloose the belt (4) until when it is possible

to withdraw the control and driven pulleys.

- Replace the toothed belt with a similar one.

- Mount the belt (4) and screw it without clamping the

screw (1) so that it can slide inside the staff slot (5).

- Adjust the belt tension by operating the screw. After

achieving a correct tension lock the lock nut (2) and the

screw (1).

- Operate the motor for some hours and check the correct

belt tension.

Figure 236

!

During this operation don’t smoke and don’t use free

flames.

Avoid to breathe the vapors coming from filter.

!

After filters replacement the supply equipment

deaeration must be carried out.

According to the applications the filter s position and the quan-

tity can change.

However the following oper ations are valid for all applications.

- Dr ain the fuel inside the filter by operating the water re-

lease screw. Collect the fuel in a container without impu-

rities.

-

Unscrew the cartridge by using acceptable tools.

- Collect the eventual fuel inside the filtering cartr idge .

- Clean the gasket seat on the support and oil slightly the

gasket on the new filtering cartridge.

- Screw manually the new filtering cartdr i ge until when the

gasket is completely on its seat.

-

Tighten using acceptable tools to 5-10 Nm torque.

Alternator belt replacement

Due to several applications the belt run can change very much.

We describe the replacement of a belt mounted on a 4−cylin-

ders motor with traditional belt tension and a 6−cylinders

motor with an automatic screw coupling.

!

Warning: with switched off motor (but still hot) the

belt can operate without advance notice.

Wait for the motor temperature lowering to avoid

very serious accidents.

2

3

1

4

5

SECTION 3 − DUTY − INDUSTRIAL APPLIC ATION

98

ENGINES

ED. FEBUARY 2003

Loading...

Loading...