70159

70158

70160

70161

70162

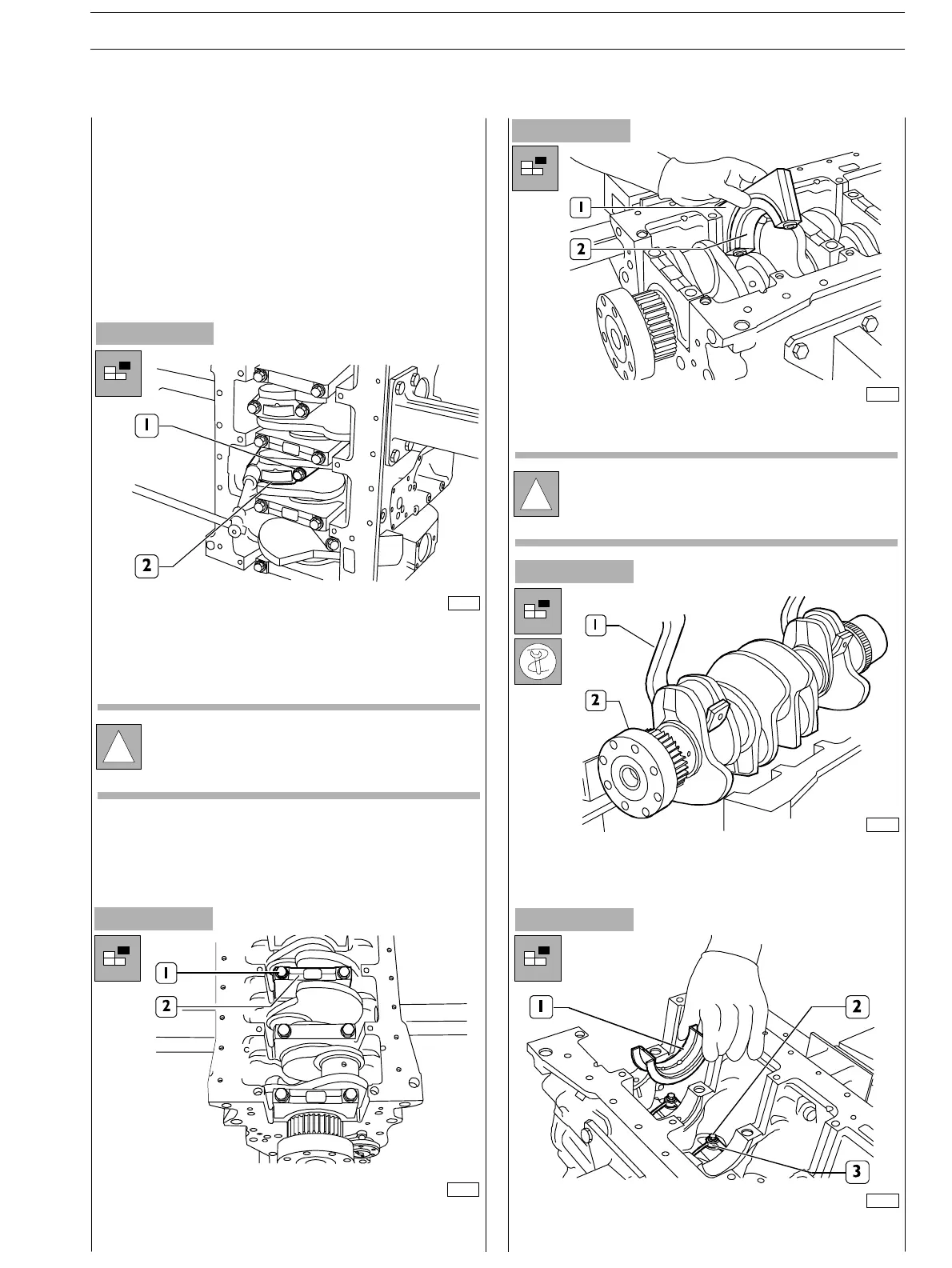

Figure 1

Figure 2

Figure 3

Figure 4

The following instructions are prescribed on th e

understanding that the engine has previously been placed on

the rotating bench and that removal of all specific

components of the equipment have been already removed

as well. (See Section 3 of the manual herein).

The section illustrates th erefore all the most import ant

engine overhaul procedures.

The following operations are relating t o t he 4 cylinder s

engine but are analogou sly applicable for the 6 cylinders.

Remove the screws (1) fastening the connecting rod caps (2)

and remove them.

Withdr aw the pistons including the connecting rods from the

top of the engine block.

Remove the screws (1) and the main bearing caps (2).

The second last main bearing cap (1) and the relevan t

support are fitted with shoulder half−bearing (2).

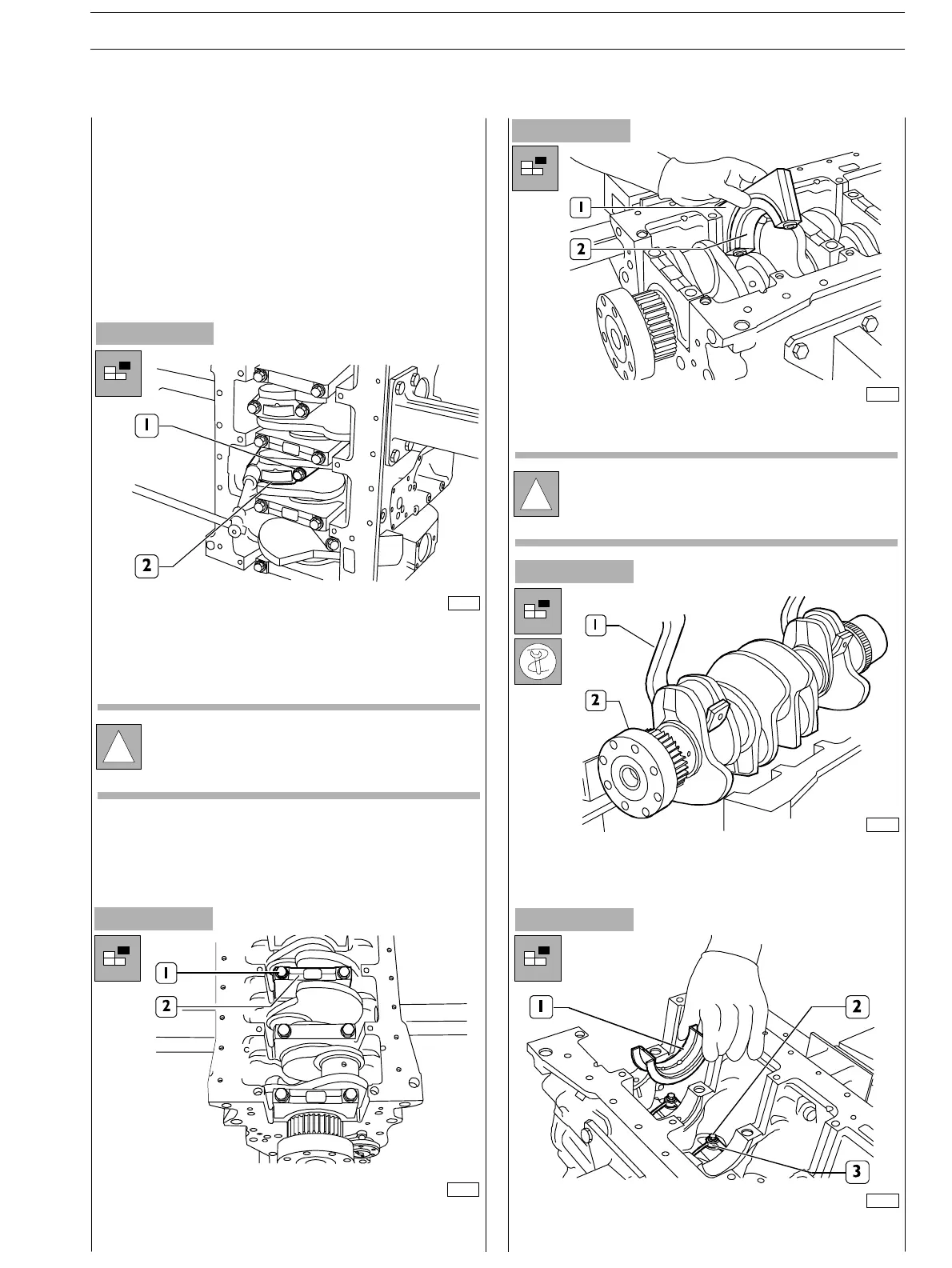

Use acceptable tools (I) and hoist to remove the output

shaft (2) from the block.

Remove the main half−bear ings (1).

Remove the screws (2) and remove the oil nozzles (3).

!

Keep the half−bearings into their housings sin ce in

case of use they shall be fitted in the same position

found at removal.

!

Take note of lower and upper half−bearing

assembling positions since in case of reuse they sh all

be fitted in the same position found at removal.

Figure 5

SECTION 4 − OVERHAUL AND TECHNICAL SPECIFICATIONS E NG I NE S

11

ED. FEBUARY 2003

ENGINE OVERHAUL

ENGINE REMOVAL AT THE BENCH

Loading...

Loading...