70202

70203

70204

70205

70206

Figure 62

Figure 63

Figure 64

Figure 65

Figure 66

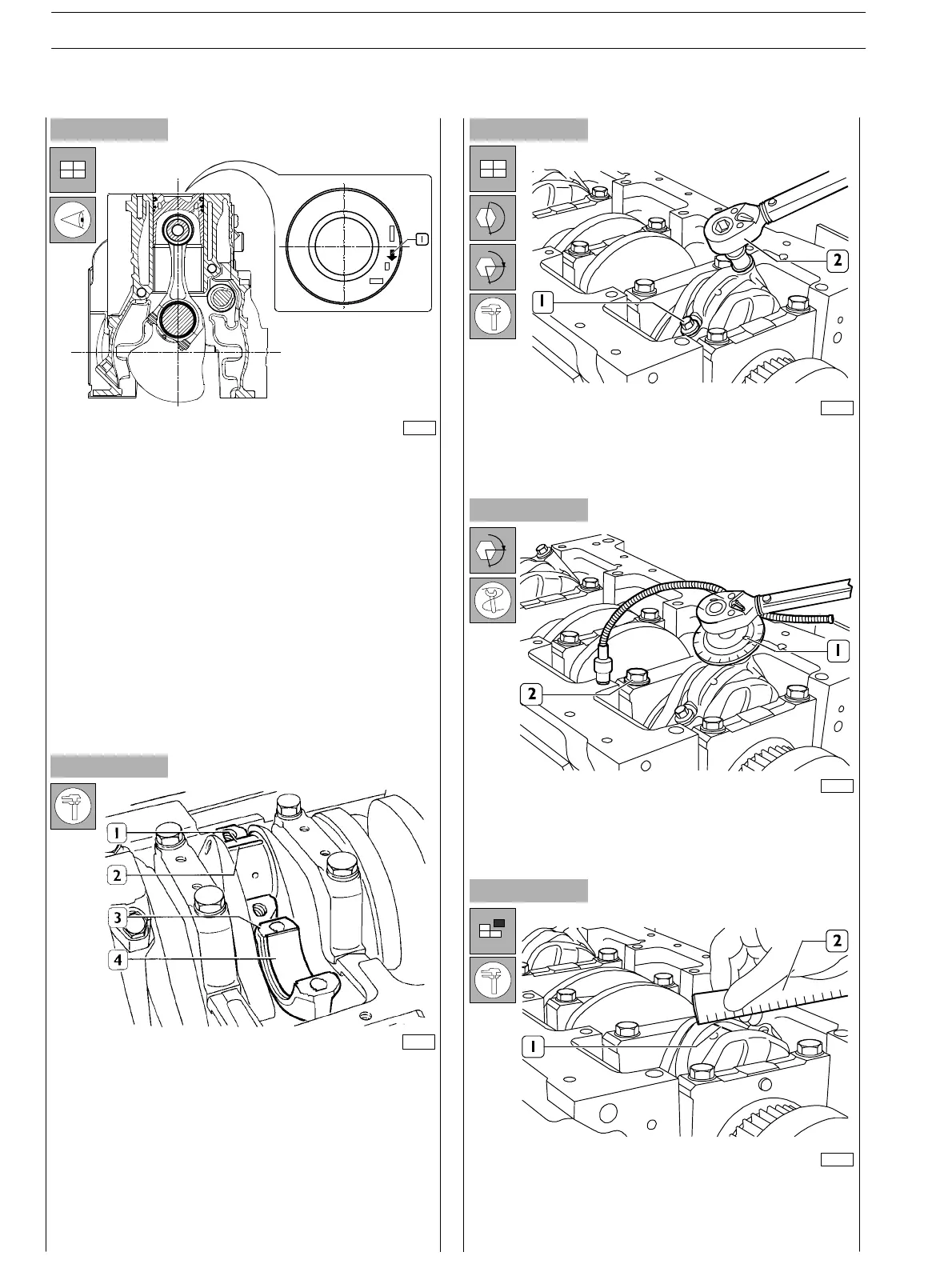

DIAGRAM FOR CONNECTING ROD−PISTON

ASSEMBLY FITTING INTO BARREL

- Split ring openings shall be displaced with each other by

120°;

- connecting rod−piston assemblies shall have the same

weight;

- the ar row marked on the piston crown shall be facing the

front side of the engine block or the slot obtained on the

piston skirt shall be corresponding to the oil nozzle

position.

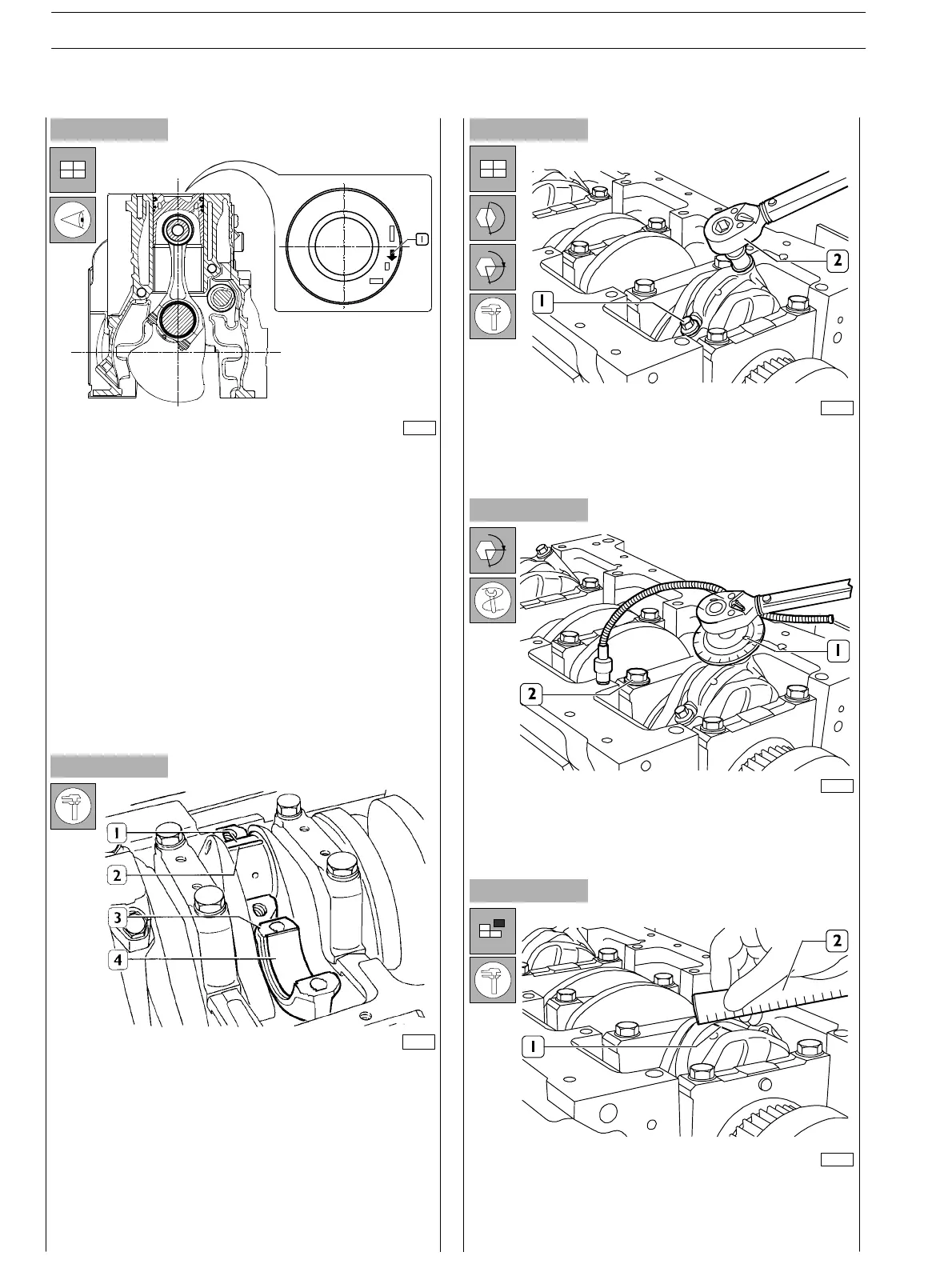

Finding crankpin clearance

To measure the clearance proceed as follows:

- clean the parts accurately and remove any tr ace of oil;

- setapieceofcalibratedwire(2)ontheoutputshaftpins

(1);

- fit the connecting rod caps (3) with the relevant half

bearings (4).

- Lubricate the screws (1) with engine oil and t hen tighten

them to the specified torque using the dynamometr ic

wrench (2).

-

Apply acceptable tools (I) to the socket wrench and

tigh ten screws (2) of 60° .

- Remove the cap and find the existing clearance by

comparing the calibrated wire width (1) with the scale

onthewireenvelope(2).

α

α

SECTION 4 − OVERHAUL AND TECHNICAL SPECIFICATIONS

28

E NG I NE S

ED. FEBUARY 2003

Loading...

Loading...