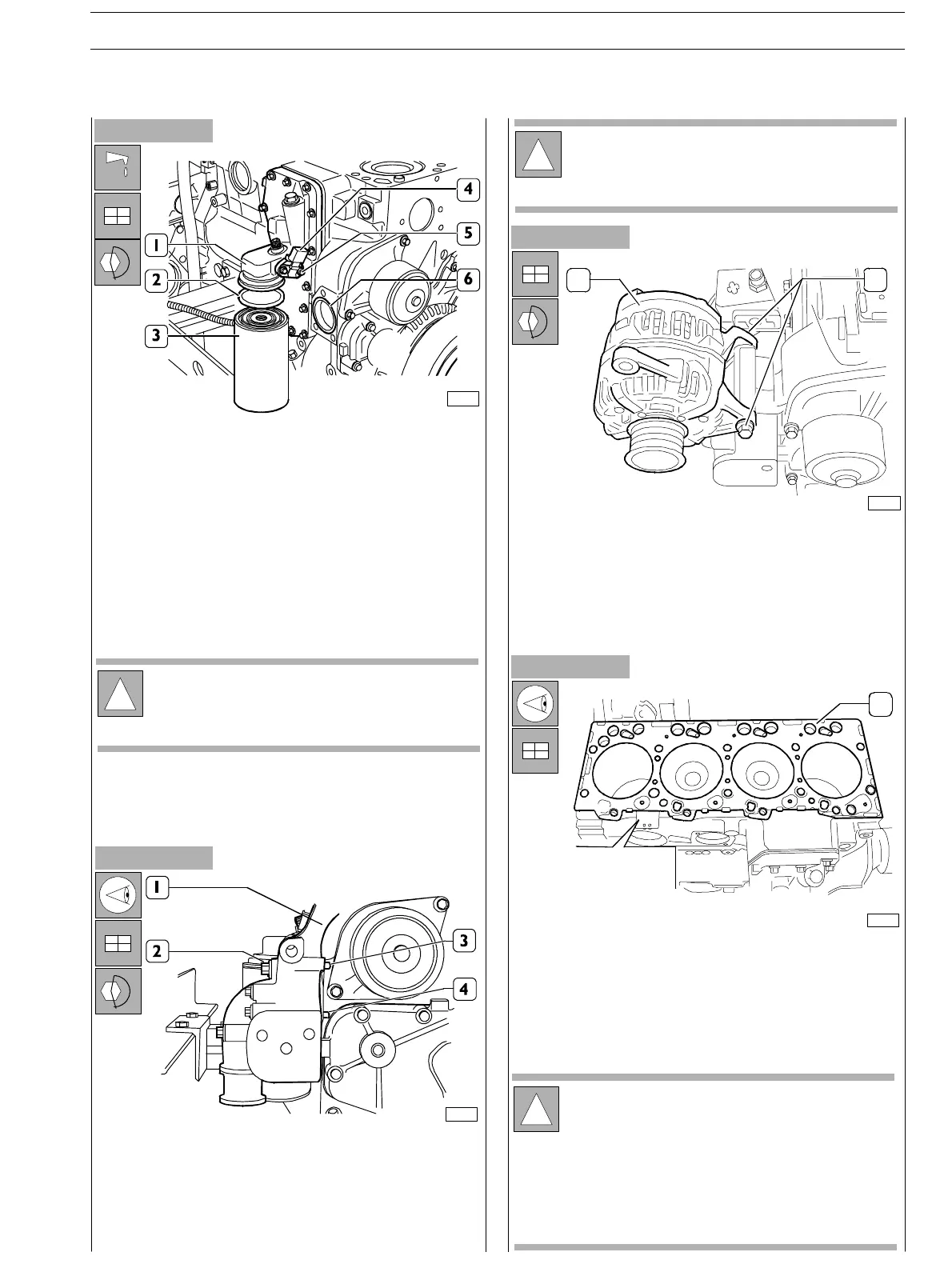

Figure 62

Figure 63

- Lubricate the fixing ring (2) using engine oil and place it

on the oil filter (3).

- Manually start the oil filter (3) on the bearing union (1)

until counter−boring, further screw up the oil filter (3)

by 3/4 turn.

- Apply, (if needed) new fixing ring on the oil

temperature/pressure sensor (4) and assemble it to the

bearing (1) tightening the fixing screws to t h e prescribed

couple.

- Assemble the alternator bearing (1) ensuring that the

pins (3 and 4) are against the engine block.

- Tighten the screws (2) and lock them to the prescribed

couple.

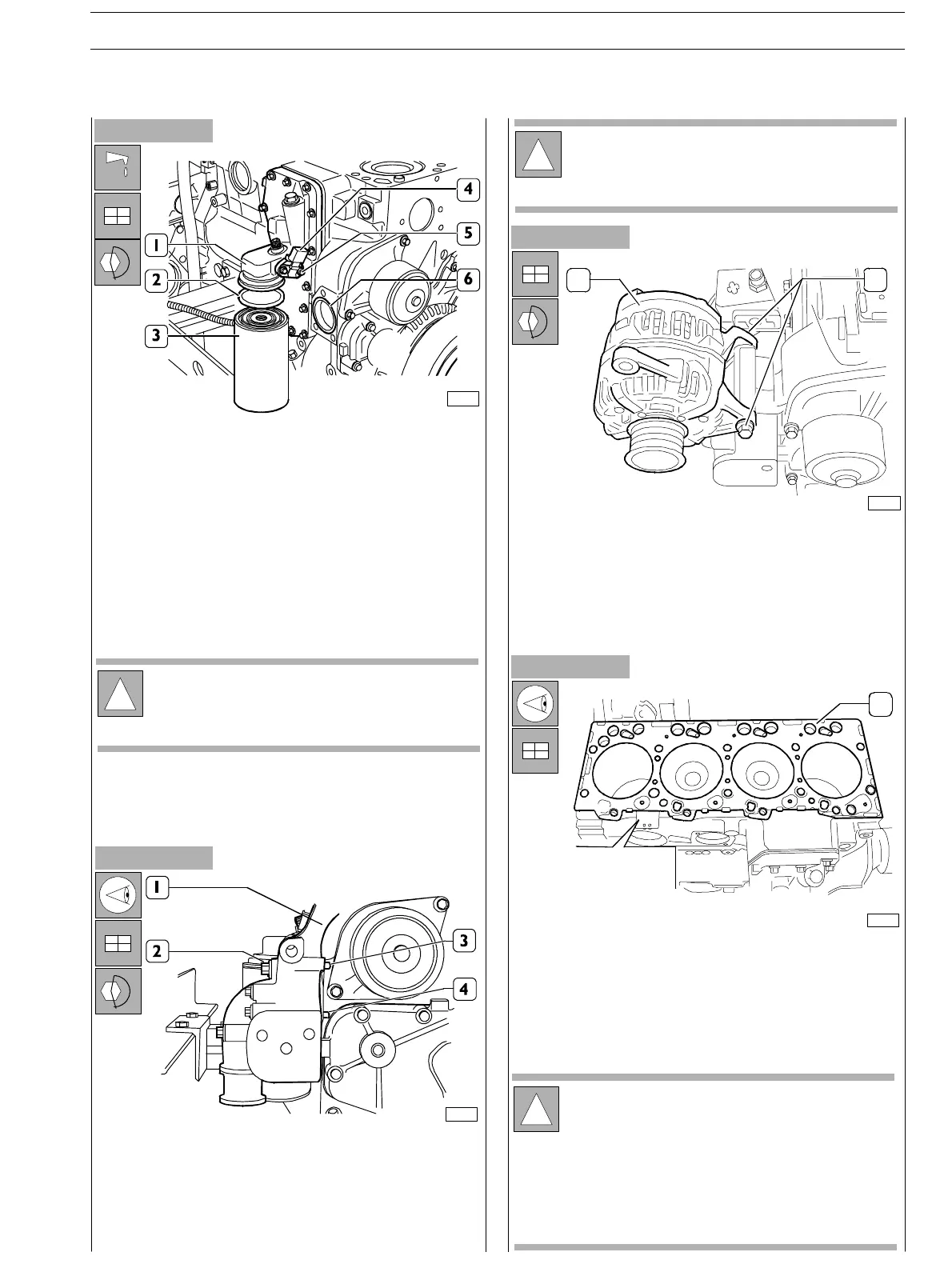

Figure 64

- Plac e the gasket (1) over the block.

The choice of the gasket’s thickness shall be made in

consideration of the cy lin der protrusion measured with

respect to the block’s upper surface.

- Place a new fixing ring on the block housing (6).

Figure 65

76113

!

In some applications, the bearing of the exchanger

shall be assembled to a screw threaded un ion

connected to the filter on the opposite side of the

engin e, throughout two pipelines (see picture 2).

76114

!

Before assembly, always check that the threads of the

ports and of the screws have no evidence of tear and

wear nor dirt.

12

75686

- Reassemble the alternator (1).

- Tighten the screw (2) and lock it t o the prescribed

couple.

75706

2830006

2830006

1

!

Verify that the engine block stand is clean.

Do no t grease the gasket. It is recommended to keep

the gasket inside packaging until assembly to the

cylinder head.

Gasket assembly shall be made following the

direction of wording printed on the gasket itself so

that this will be readable as indicated in the picture.

SECTION 3 − DUTY − INDUSTRIAL APPLICATION E NG I NE S

25

ED. FEBUARY 2003

zs

Loading...

Loading...