Figure 180

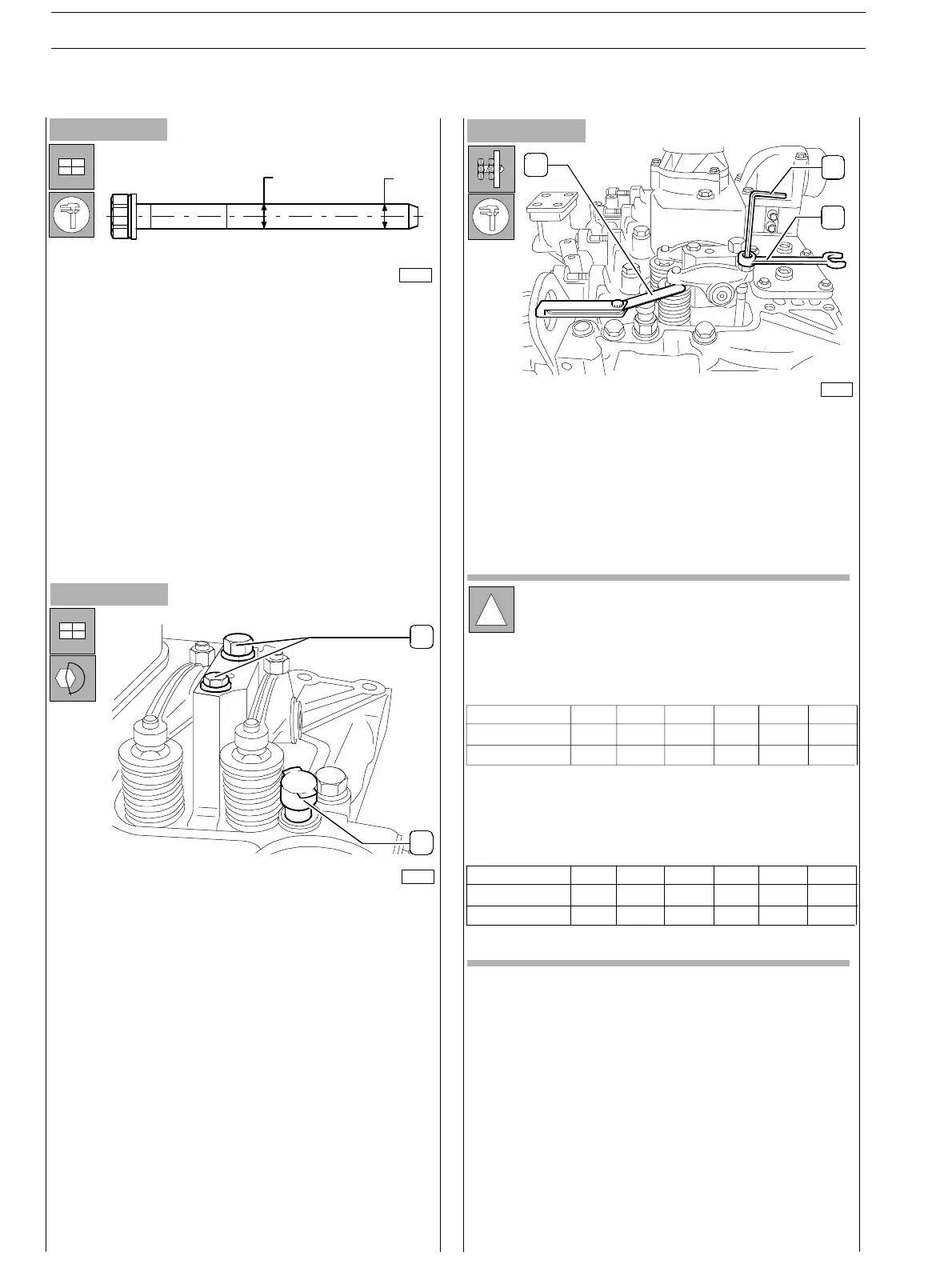

Figure 181

- Tighten the screws (2) to the prescribed couple and

assemble water temperature sen sor (1).

!

In order carry out a quicker adjustment of the

working slack between rocker arms and valves,

proceed as following:

Rotate the engine drive shaft, balance the valves of

cylin der 1 and adjust the valves identified by star

symbol, as indicated in the following table:

Adjust the slack between rocker arms and valves using socket

wrench (1), point wren ch (3) and feeler gauge (2).

Correct working slack is:

− suction valves 0.30 0.05 mm

− exhaust valves 0.55 0.05 mm.

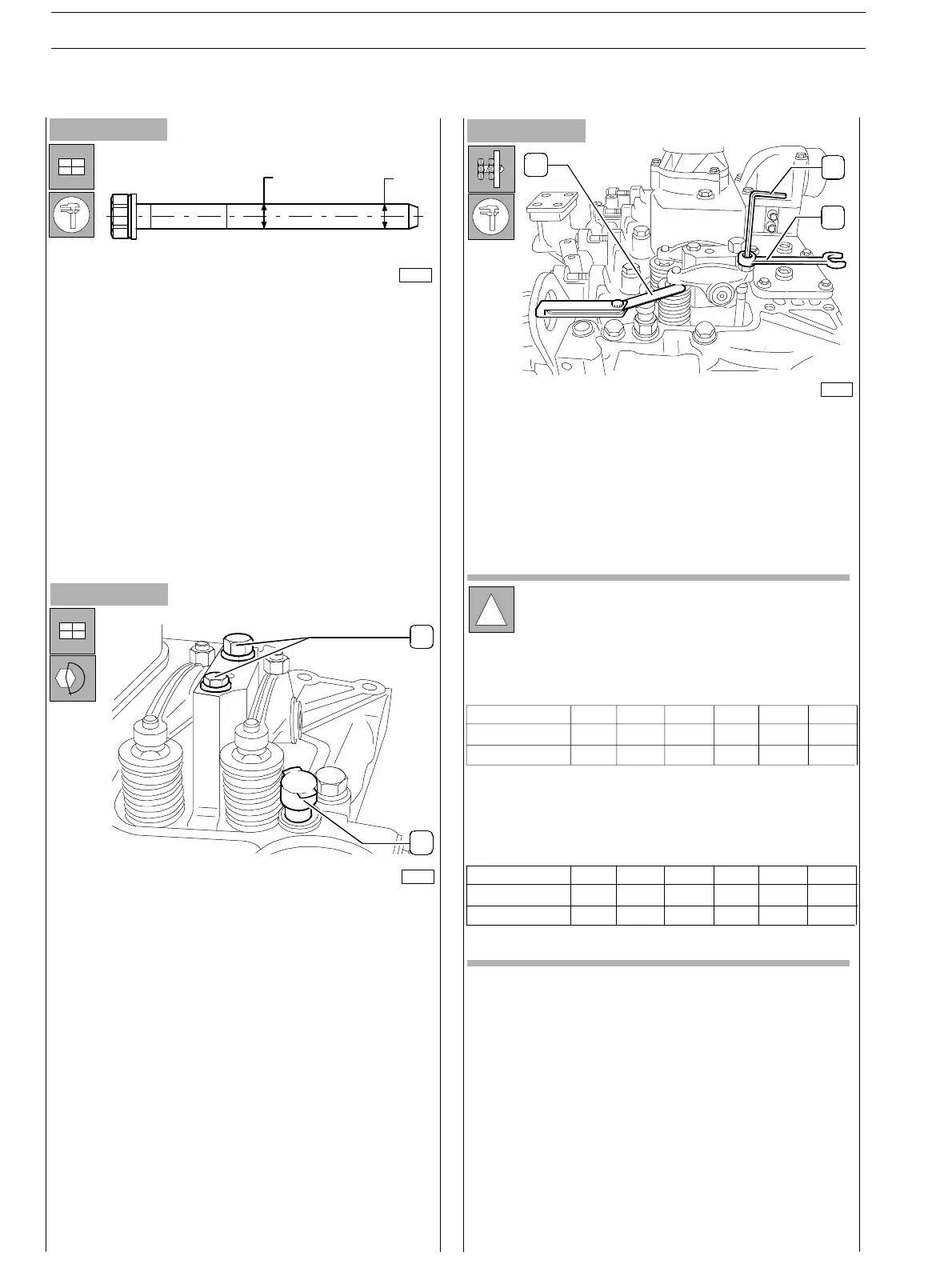

Figure 182

D1D2

75703

- Insert the tappet driving rods and the Rocker Arm unit.

Before usin g the fixing screws again, measure them twice

as indicated in the picture, checking D1 and D2

diameters:

if D1 − D2 < 0,1 mm the screw can be utilised again;

if D1 − D2 > 0,1 mm the screw must be replaced;

1

2

75683

75806

2

1

3

Rotate th e engine drive shaft of 360 deg., balance the

valves of cy linder 6 and adjust the valves identified by

star sy mbol, as indicated in the following table:

Cylinder n.

Suction

Exhaust

1

234

*

*

*

*

*

−

−

−

56

−

−

Cylinder n.

Suction

Exhaust

1

234

−

− * −

−

−

*

*

56

*

*

*

−

*

−

SECTION 3 − DUTY − INDUSTRIAL APPLICATION

58

E NG I NE S

ED. FEBUARY 2003

Loading...

Loading...