73/89

6 MMA DC WELDING

This welding machine is suitable for welding all types of electrodes, with the exception of cellulosic (AWS 6010).

♦ Make sure that the G switch is in position 0, then connect the welding cables, observing the polarity re-

quired by the manufacturer of the electrodes you will be using; also connect the clamp of the ground ca-

ble to the workpiece, as close to the weld as possible, making sure that there is good electrical contact.

♦ Do not touch the torch or the electrode holder and the earth clamp simultaneously.

♦ Turn on the machine using the G switch.

♦ Select MMA process.

♦ Adjust the current based on the electrode diameter, welding position and type of weld to be made.

♦ Always remember to shut off the machine and remove the electrode from the clamp after welding.

WARNING

Beware of electrical shocks

When the main switch is in ON position, the electrode and the non-insulated part of the electrode holder are live.

Therefore, make sure that the electrode and the non-insulated part of the electrode holder do not come into contact

with electrically conductive or earthed persons or components (e.g. outer casing, etc.).

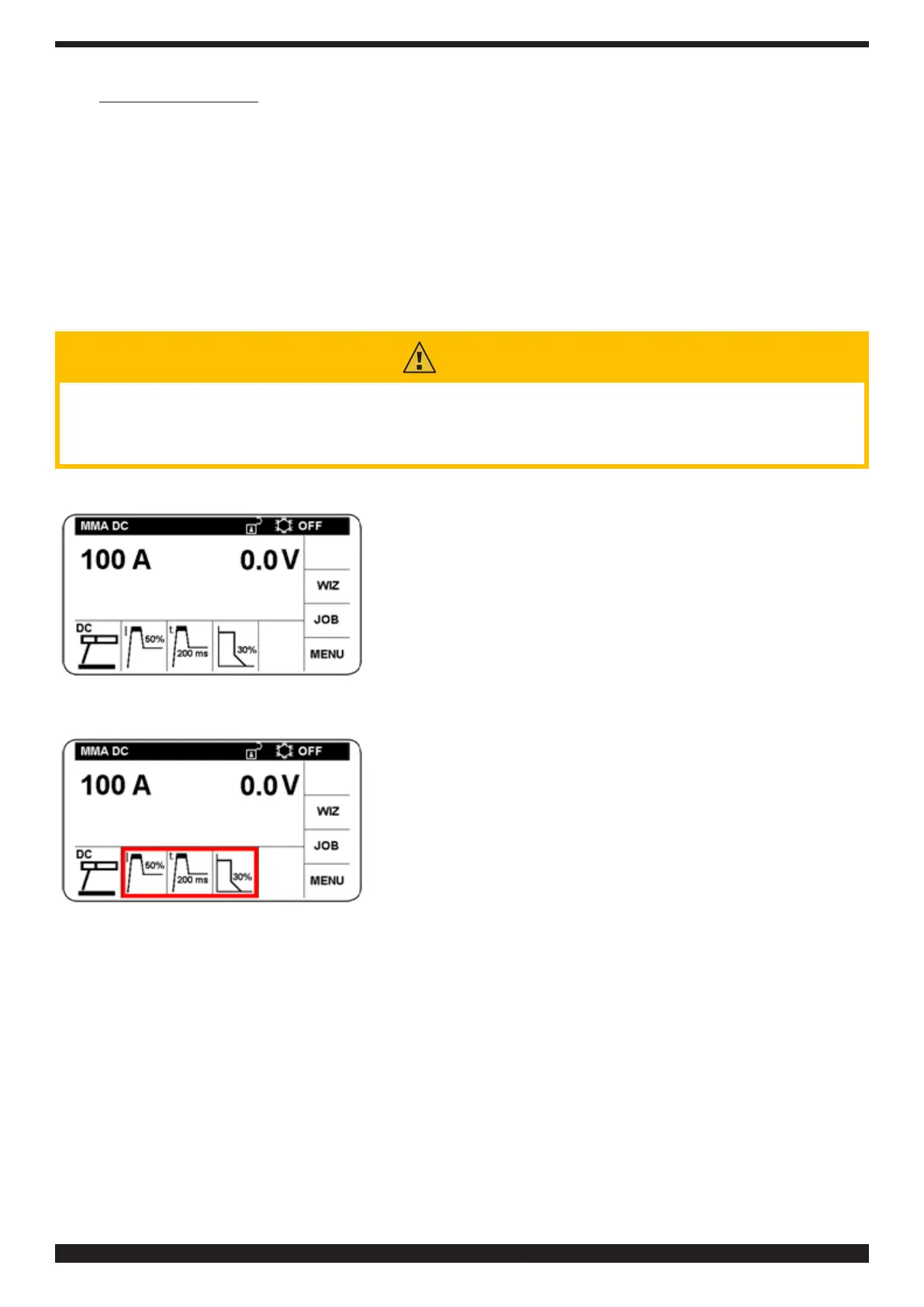

To select this process, see section 5.1.

Turn knob B to change the welding current.

To modify the welding parameters, proceed as follows:

Select and conrm the sector relative to welding parameters.

Conrmation enables access to the following welding parameters:

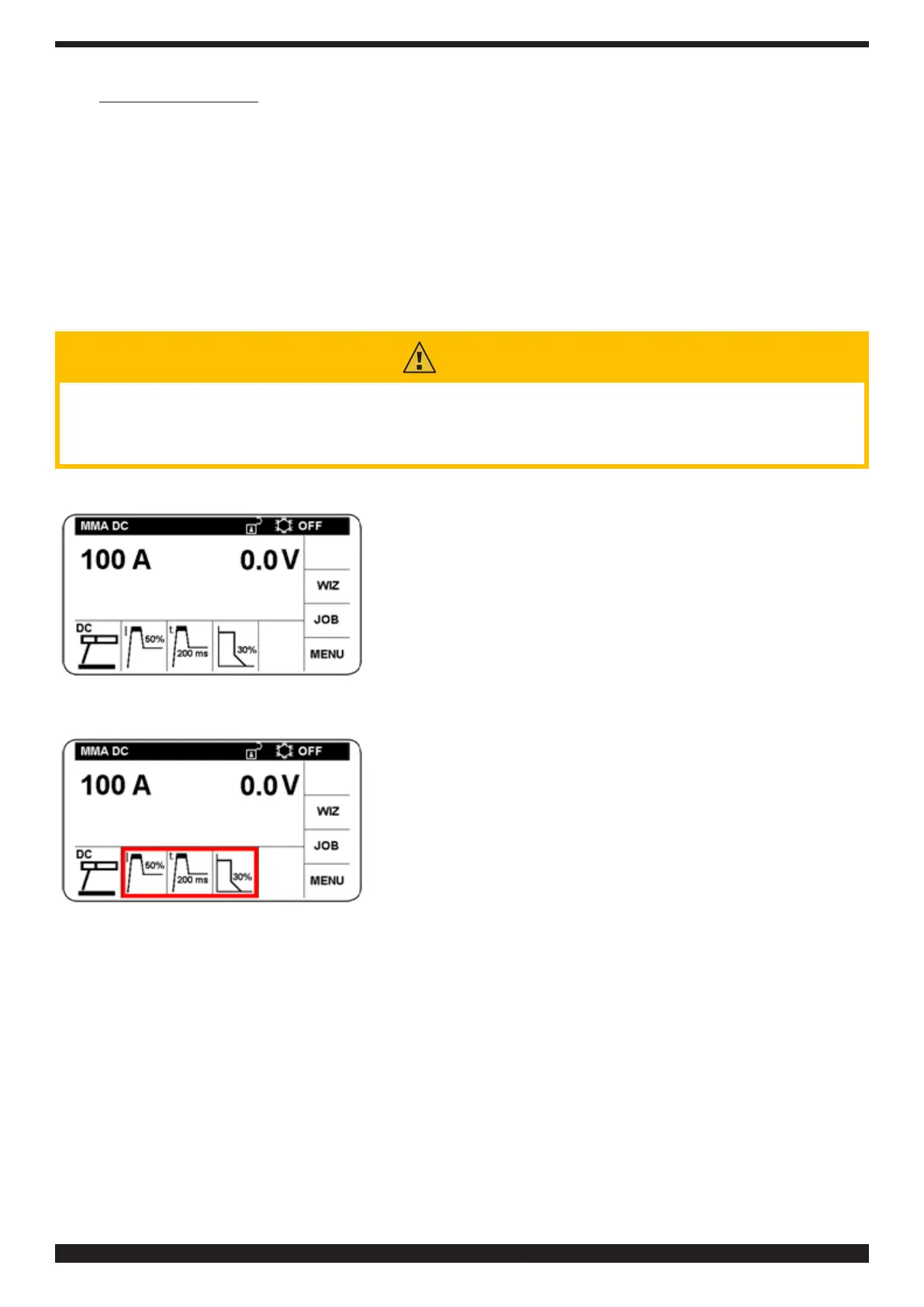

♦ HOT-STARTCURRENTadjustablefrom0to100%oftheweldingcurrent(withsaturationatmaximum

current). Percentage of current added to the welding current to enable arc ignition. The parameter ac-

tivatesinred.Conrmandadjusttheparameter.Conrmationenablesautomaticpassagetothenext

parameter, or turn knob B to select the desired parameter.

♦ HOT-START TIME adjustable from 0 to 500 ms.

♦ ARCFORCEadjustablefrom0al100%.(withsaturationatmaximumcurrent).Thisovercurrentfacilitates

transfer of melt metal.

Loading...

Loading...