68/89

5�6 TIG AC (only Item No 558)

AC welding is used to weld aluminium and aluminium alloys. The procedure involves continuous changes in the

polarity of the tungsten electrode. Two phases are available (half-waves): a positive phase and a negative phase. The

positive phase causes the aluminium oxide layer on the surface of the material to break down (cleaning effect), while

at the same time a cap forms on the tungsten electrode tip. The size of this cap depends on the length of the positive

phase. It should be noted that an over-large cap leads to a diffuse and unstable arc with reduced penetration. The

negative phase cools the tungsten electrode while generating the necessary penetration. It is important to choose the

correct time ratio (balance) between the positive phase (cleaning effect, cap size) and the negative phase (penetration

depth).

5�6�1 AC settings (SECTOR U)

Based on the AC process selected in the U-sector of the main screen, the icons corresponding to the related welding

parameterswillappear.SelectandconrmUsectortoaccessadjustmentoftheweldingparametersasinTable5.

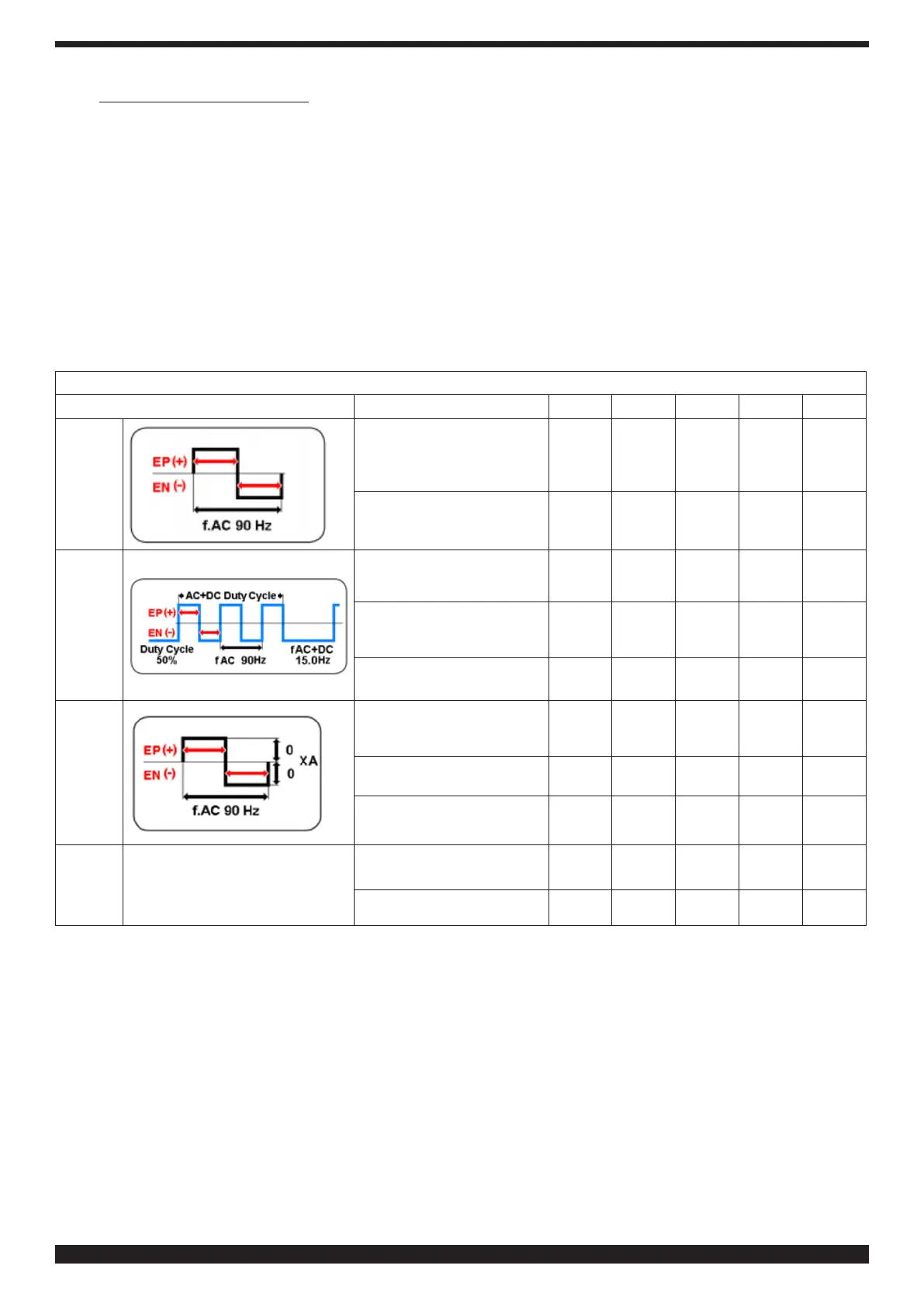

Table 5 - AC PROCESS PARAMETERS SETTING

Process Description Min.

Def

Max UM Sol.

TIG AC

Balancing AC

EP 8

EN-8

0.0

EP-8

EN 8

- 1

Frequency

AC 50 90

200

Hz

1

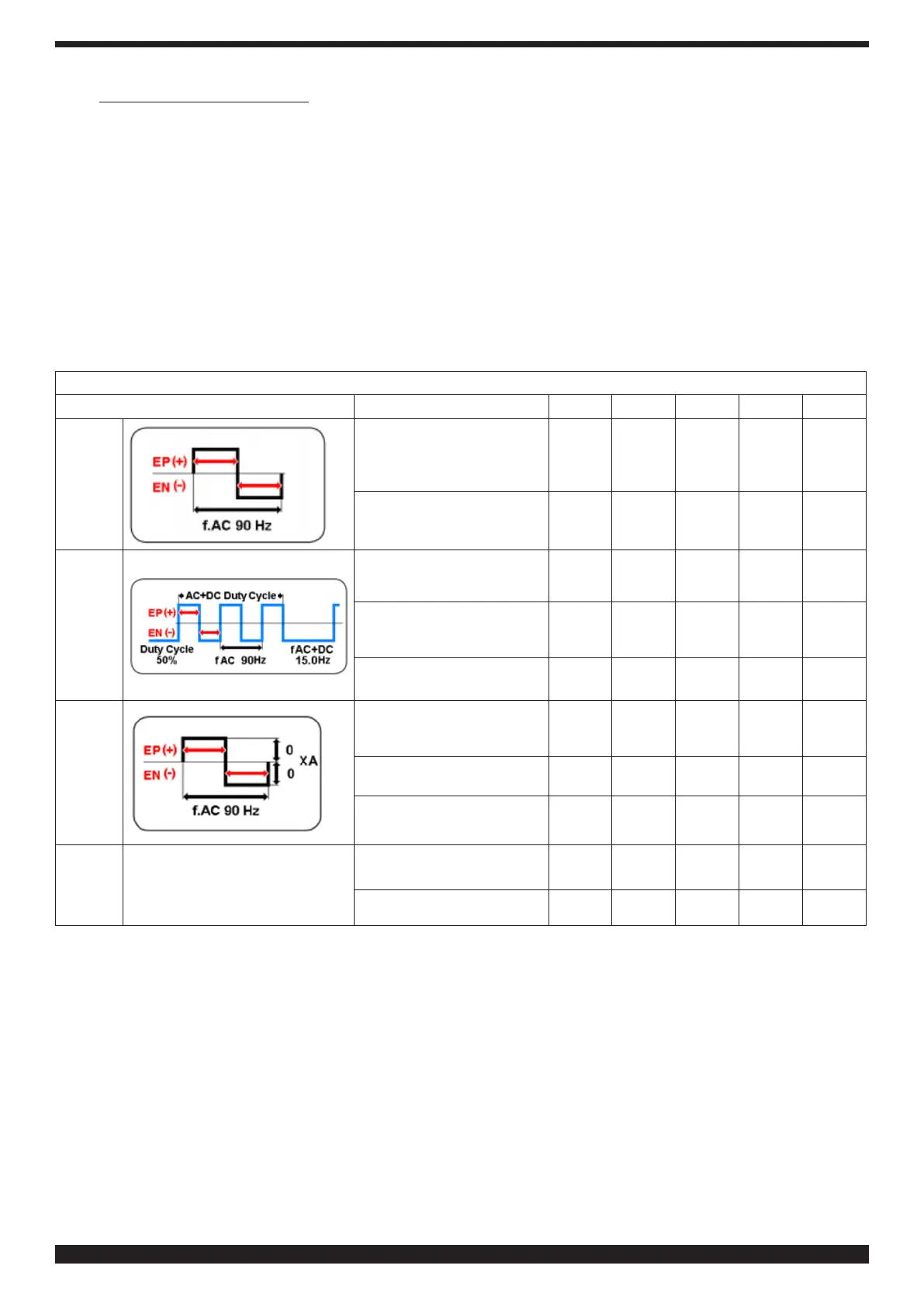

TIG

AC+DC

Balancing AC

EP 8

EN-8

0.0

EP-8

EN 8

- 1

Frequency

AC

50

90

200

Hz

1

Duty Cycle

20

50

90 % 1

TIG

AC-XA

Balancing AC

EP 8

EN-8

0.0

EP-8

EN 8

- 1

Frequency

AC 50 90

200

Hz

1

Adjustment

Amplitude AC

EP-1

EN 1

EP-50

EN 50

EP-80

EN 80

% 1

MMA

AC

HOT START

HOT START

Current

0.0

50

100

% 1

HOT START

Time

0.0

200 500

ms

10

Select the desired parameter. The parameter activates in red.

Conrm and set the selected parameter. Then press to conrm the setting and automatically move on to the next

parameter, or turn knob B to select the desired parameter.

Loading...

Loading...