VeriFast

TM

MicroView 1.0 – User Manual – Version 1.9

11

Equipment and Process Overview

Intended Use of Equipment

The VeriFast™ MicroView 1.0 is a stand-alone controller that allows simple integration of analog

linear position sensing devices into resistance welding systems that require digital I/O.

The VeriFast™ MicroView 1.0 is available in three configurations:

• VeriFast™ MicroView 5-port Dual Device – can integrate up to two (2) of the following

devices:

VeriFast™ LPT

Generic device that operates on 0 to 10 V

• VeriFast™ MicroView 10-port Dual Device – can integrate up to two (2) of the devices

listed above.

• VeriFast™ MicroView 5-port Single Device – can integrate only one VeriFast™ LVDT.

No other devices can be integrated with this configuration.

Regardless of configuration, each device must be connected to a channel on the MicroView

controller. For each channel, the user can teach 15 schedules. Every schedule can monitor up to

four (4) linear positions, with a set of independent upper/lower tolerance window that can be

individually set for each position.

The MicroView can output four (4) digital outputs per channel. These digital outputs are controlled

by a nominal position, with tolerances taken into account. When the analog signal is within the

window, the corresponding digital output is HIGH.

In addition to the four digital outputs per channel, each channel has a digital output signal

indicating if the device has been bypassed (Bypassed is logic HIGH).

The On-board storage has the ability to store up to 500,000 points of data per input device.

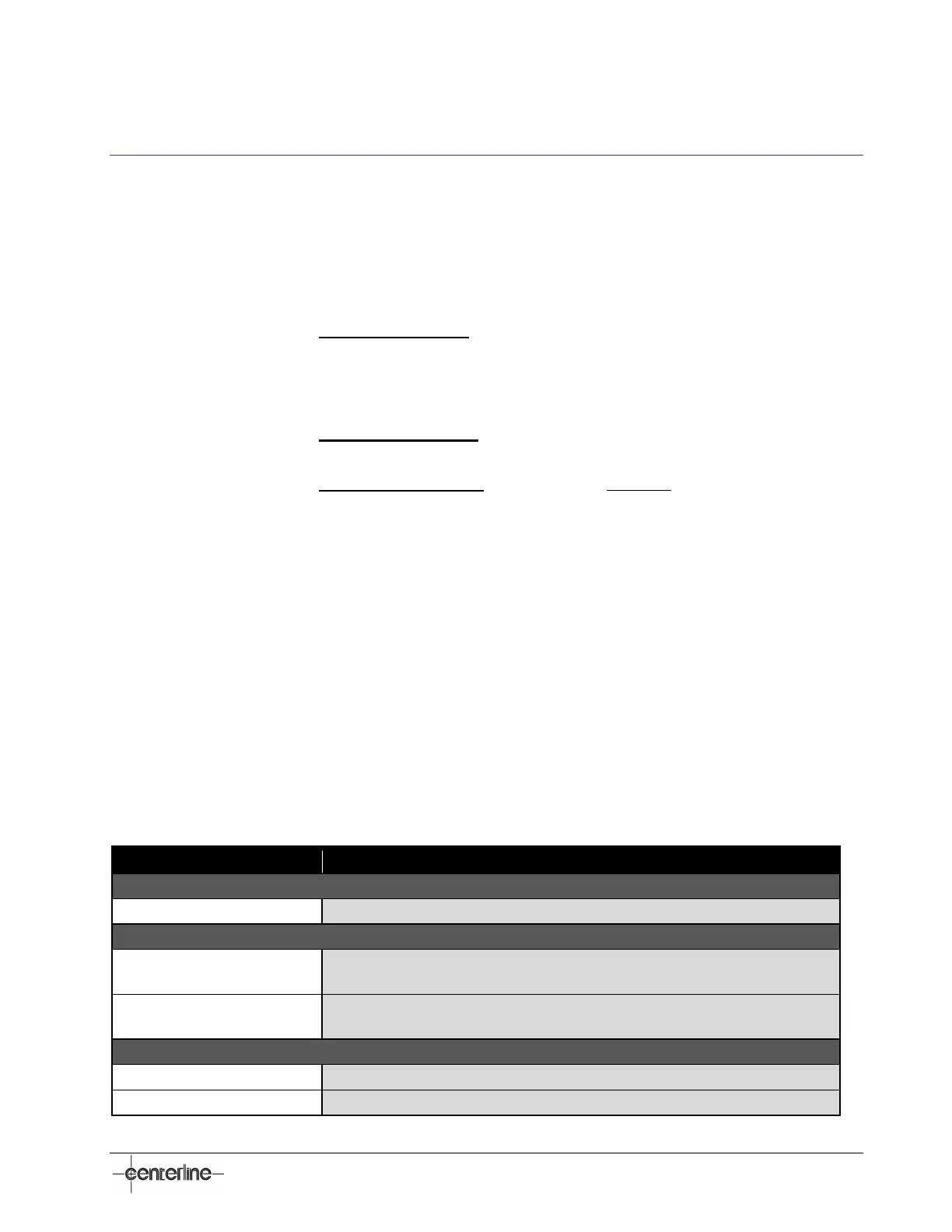

Technical Specifications

Table 1 – Technical Specifications of VeriFast™ MicroView 1.0

18 VDC – 30 VDC, 1 A max @ 24 VDC

Input

PNP, High True

V

IL

= 2.4 VDC Max., I

IL

= 3.0 mA Max., V

IH

= 30 VDC Max.

Output

PNP, Low True

V

OL

= 0.8 VDC Max., I

OL

= 50 mA Max., V

OH

= 30 VDC Max.

Operating Temperature Range

150 mm x 220 mm x 110 mm (5-7/8 in. x 8-5/8 in. x 4-1/4 in) (Width x Height x Depth)

Loading...

Loading...