36

VeriFast

TM

MicroView 1.0 – User Manual – Version 1.9

• – Press this button and a keypad will be displayed, allowing for renaming the

selected schedule.

• Schedule Number – This field identifies the currently selected schedule number. To

navigate through the schedules, use the buttons on the left. Ensure that the desired

schedule remains selected.

• Schedule Name – This field identifies the name of the current schedule (if pre-defined).

The user can navigate between the schedules by using the buttons on the left.

Ensure that the desired schedule remains selected.

• Live Data field displays the instant value corresponding to the live position of the monitored

device. For example, for a VeriFast™ LVDT unit connected to the MicroView as Device 1, this

field will indicate the real time position of the weld pin on the VeriFast™ LVDT unit)

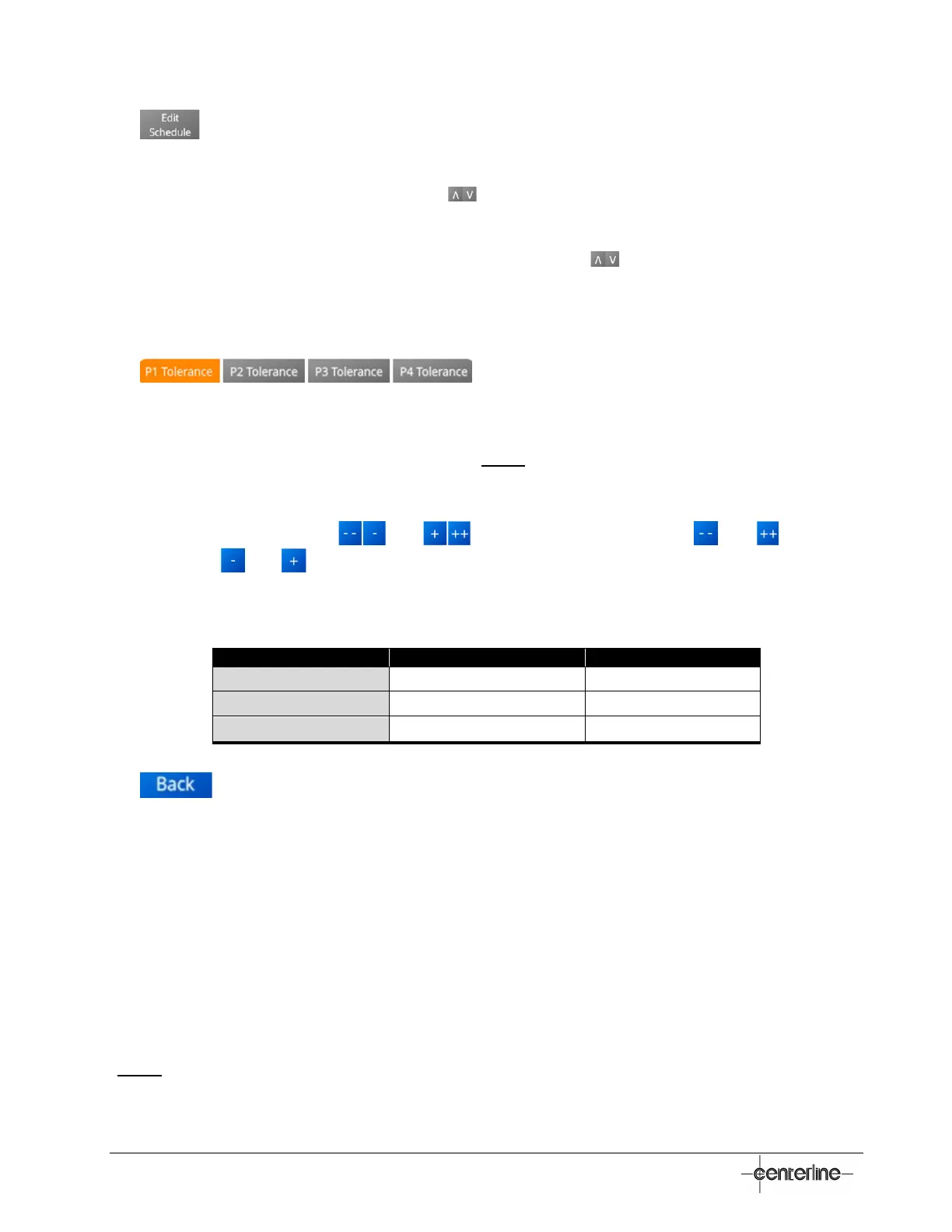

• – Press on the desired button to select

(highlight) the position/status for which the tolerances will be established (P1, P2, P3, or

P4). Ensure that the desired selection remains highlighted.

• Nominal (position value) – This field indicates the already taught value (if any) for the currently

selected position/status (P1, P2, P3, or P4). (Note: This value corresponds to the Nominal

Position Values shown in Figure 13 – Teach Screen on page 31).

• Set Tolerance – The tolerances for each position/status (P1, P2, P3, or P4) are established

(set) on this field. Use the and buttons to adjust the values ( and by

hundreds, and by tens). For minimum and maximum tolerance intervals that can be set

in this field for each type of units, see Table 7 below.

Table 7 – Minimum and Maximum Tolerances for Microview

Counts ± 0 ± 2000

Millimeters ± 0 ± 1.465

Inch ± 0 ± 0.058

• – Press this button to return to the previous menu.

Scaling Screen

The Scaling procedure is used to attune the MicroView unit for accurate measuring in mm or

inches during operation. Without proper scaling, measuring in mm and inches will provide

inaccurate readings during operation. Using counts during operation does not require scaling.

The MicroView must be scaled at the initial setup, and subsequently whenever a device is

connected to the MicroView unit.

Scaling must be done individually for each device connected to the MicroView using any of the

given measuring units (mm or inch).

(Note: The Scaling screen is accessible from the Maintenance Settings Screen (see page 34

)).

Loading...

Loading...