1 Operational Manual

signal .(Optional)

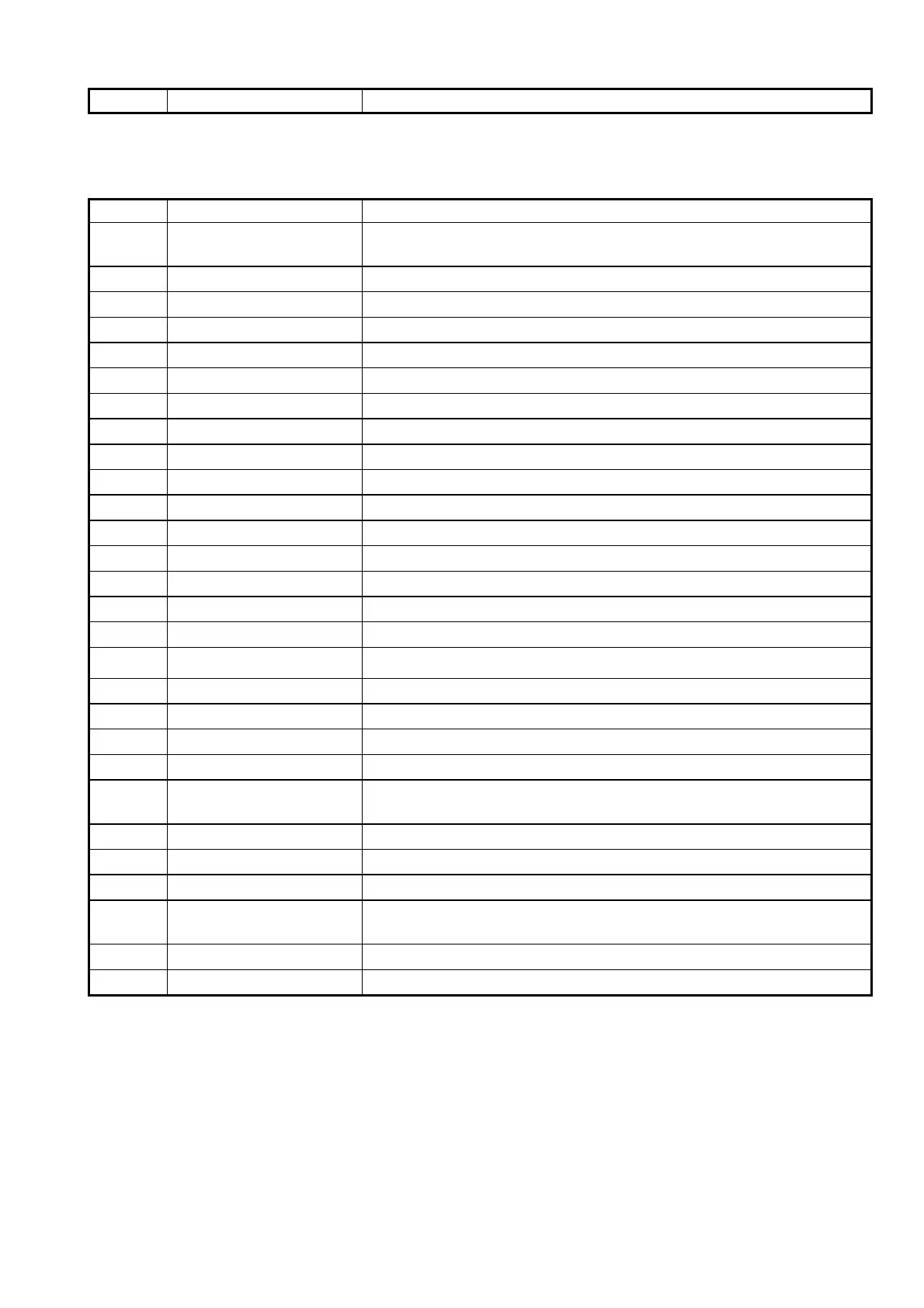

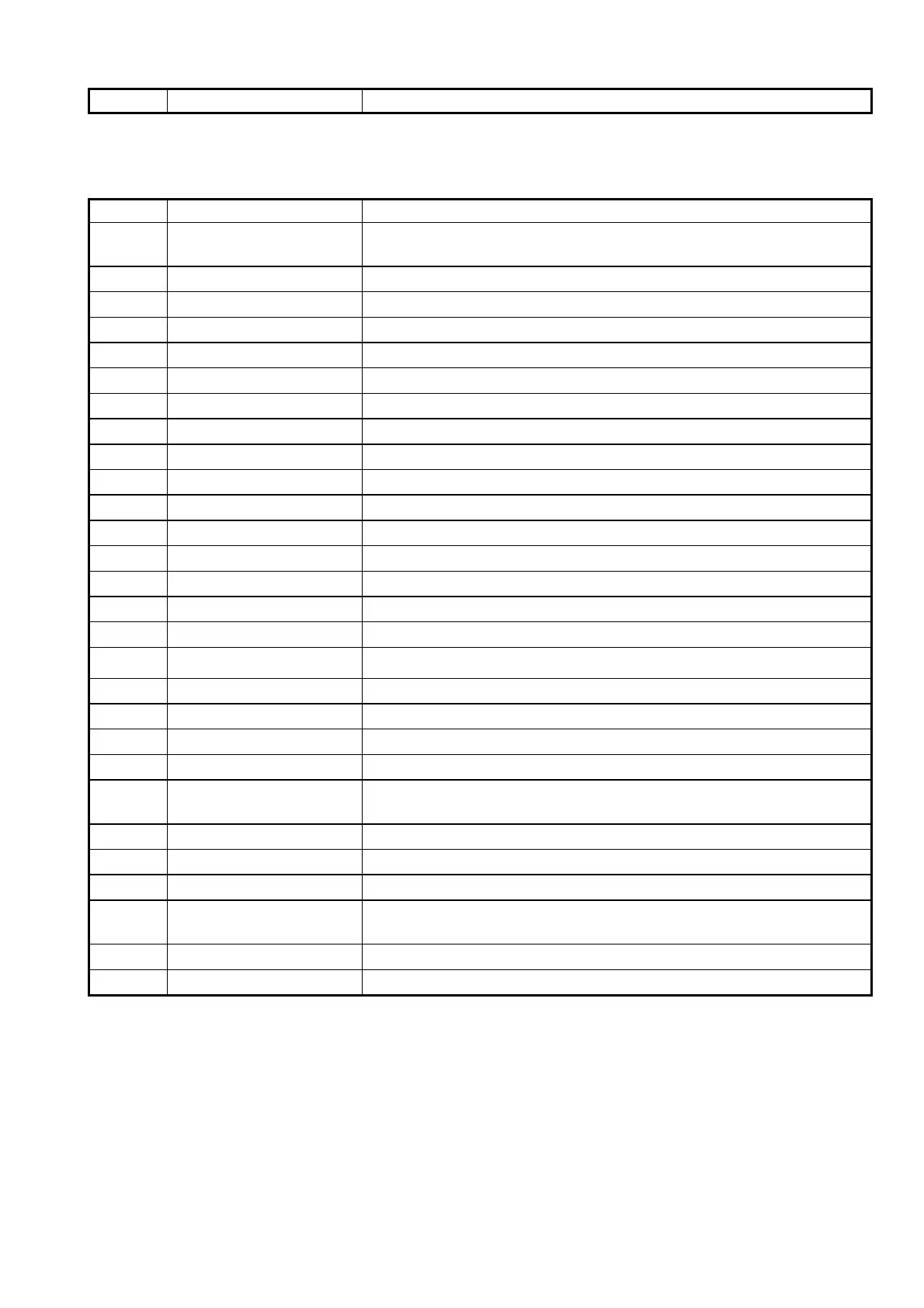

No. Content Description

09

Core 1 Out L.S When chosen as core 2 L.S function, used as core 2 out stop signal.

(Optional)

10

Nozzle Guard Purge guard closed signal.(Optional)

11

Photo Cell Photocell detects signal at auto mode.

12

Clamp Cyl. Cl.End Accumulation pressurized signal.

13

Spare Spare

14

Spare Spare

15

Spare Spare

16

Motor Start-Up Motor Y to running confirmation signal.

17

Gear Pitch Signal 1 Gear pitch signals 1 confirmation signal.

18

Gear Pitch Signal 2 Gear pitch signals 2-confirmation signal.

19

Lock-Up Open Lock-up open confirmation signal.

20

Lock-Up Close Lock-up close confirmation signal.

21

Cylinder returns signal Position cylinder backward confirmation.

22

Clamp Cylinder. Relief High-pressure cylinder leakage pressure switch.

23

Ejector Back Confirm Hydraulic Ejector returns Signal.

24

Door decelerate Pneumatic door closing deceleration signal.

25

Door decelerate Pneumatic door opening deceleration signal.

26

mold injector returns Ejector backward stop proximity switch signal.

27

Spare Spare

28

Hyd. Motor Overload Pump motor overload signal.

29

Hyd. Oil Temp. High Emergency stop input for pneumatic door.

30

Mold Screw Count

Signal

Mold Screw counter signal input .(Optional)

31

Mold Ad Count Sig. Mold height adjustment signal input.

32

Inj. Front Door L.S Input signal “OFF” means robot in line.

33

Inj. Rear Door L.S Robot interlock signal, when “ON” mode open1 close in allowed.

34

Robot controls injector

forward

Interlock input between robot and ejector, when “ON” ejector

forward is allowed.

35

Robot opens mold Confirms signal of part taken- out by robot.

36

Mold Screw In L.S Mold Screw forward stops L.S signal.

04/08/13

112

Loading...

Loading...