1 Operational Manual

C.c) Switch menu (09) to menu (01); press to have molds sit tight. The

molds should be in a closed state. Use mold clamps to stabilize molds on the

machine and remove mold hangers.

C.d) Mold has no clamping force.

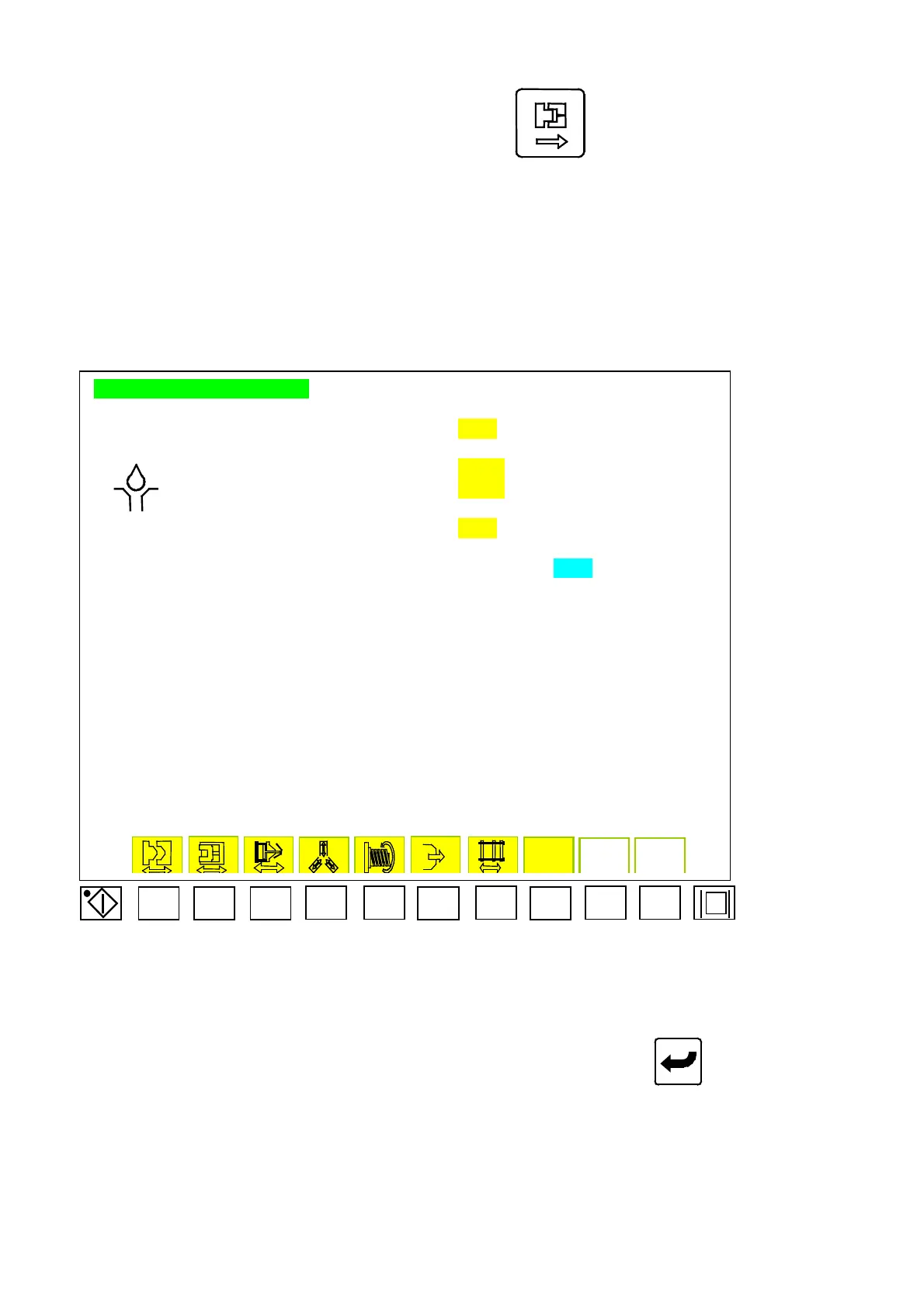

2.12 Lubrication Setup

LUBRICATION SETTING

TOGGLE SYSTEM LUBRICATION AT EVERY GGGGG CYCLES

NEXT LUBRICATION AT KKKKK CYCLE LATER

LUBRICATIN TIME

HHHH.H SEC

LUBRICATIN MONITORING TIME

IIII.I SEC

GREASE LUBRICATION AT EVERY

JJJJJ CYCLES (BY MANUAL)

NEXT LUBRICATION AT LLLLL CYCLE LATER

GREASE LUBRICATION ATALARM RESET

RESET

Menu 10

F1 F2 F3

F4 F5

F6

F7

F8

F9 F10

Move cursor to the parameter of lubrication. Key in desired digits and press

to complete a

correction. Code descriptions for Menu (10) are as follows:

A)

“

GGGGG

”

: mold counts before every toggle lubrication. Computer program counter

code

“

Cnt 18

”

.

B)

“

HHHH.H

”

: Time for toggle lubrication. Computer program timer code

“

Tim 28

”

.

C)

“

IIII.I

”

: Time of monitoring. Computer program timer code

“

Tim 29

”

.

04/08/13

58

Loading...

Loading...