1 Operational Manual

2.38 Input Node Monitoring of Computer

2.38.1 Input Node Monitoring of Computer For Toggle Clamping

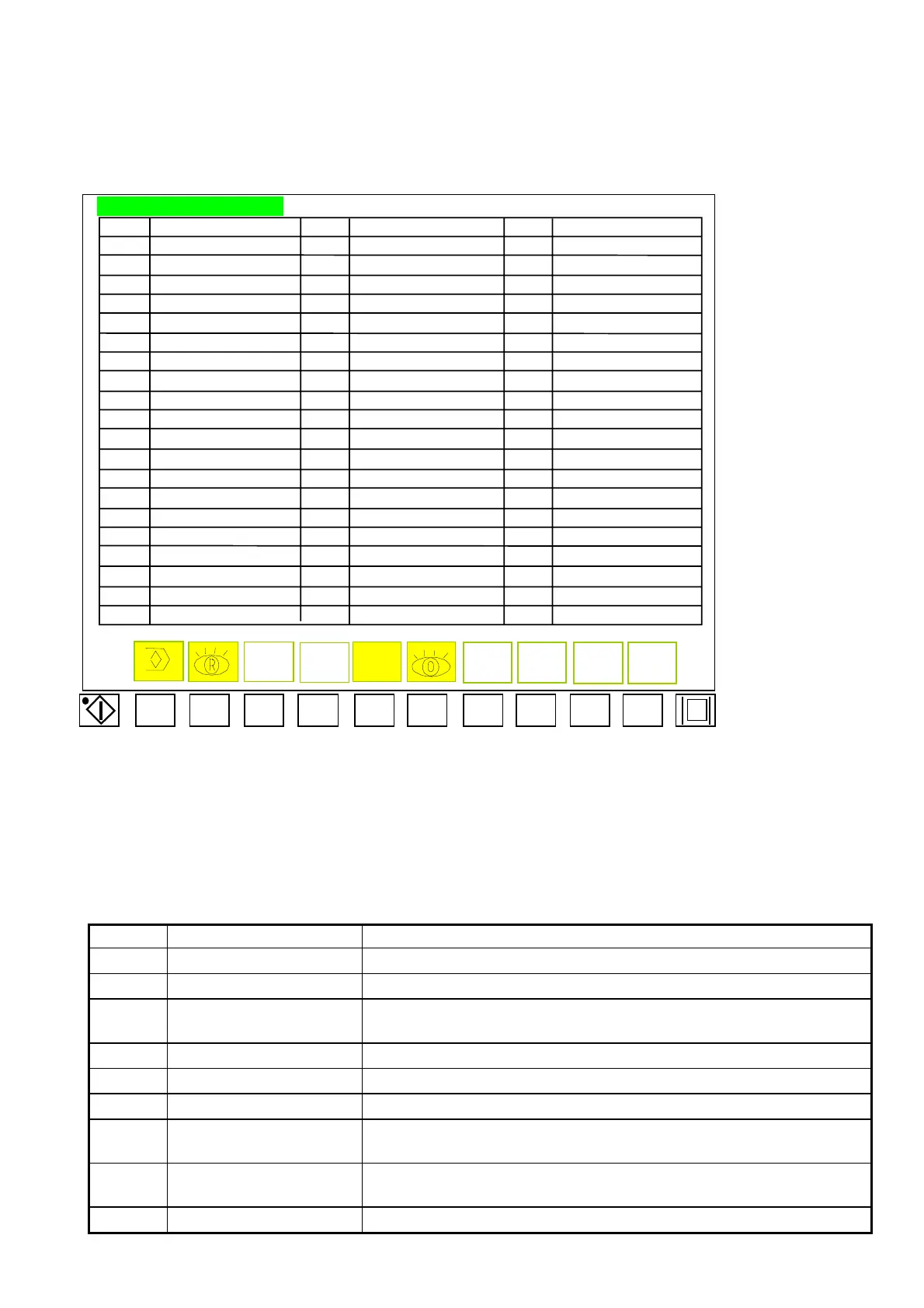

INPUT MONITORING PAGE

NO. CONTENT NO. CONTENT NO. CONTENT

RONT DOOR L.S BACK DOOR L.S 02 SAFE DOOR AUX L.S

NOZZLE CONTACT 04 MIN. MOLD TH. L.S. 05 MAX. MOLD TH. L.S.

CORE 2 IN L.S 07 CORE 2 OUT L.S 08 CORE 1 IN L.S

09 CORE 1 OUT L.S 10 NOZZLE GUARD 11 PHOTO CELL

12 SAPRE 13 SAPRE OT-LUBRICATION

15 SAPRE 16 SAPRE 17 SPARE

18 SPARE 19 SAPRE 20 SAPRE

21 SPARE 22 SPARE 23 EJECTOR BACK

P DOOR CL BREAK 25 P DOOR OPEN BREAK 26 MOLD EJECTOR BACK

27 M.T. MOTOR OVER 28 HYD. MOTOR OVER 29 SPARE

30 UNSCREW COUNTER 31 MD. AD. COUNT SIG. ROBOT CONNECTING

33 ROBOT RETURN 34 REBOT-EJECT OUT 35 ROBOT PICK-UP

UNSCREW IN LS. 37 UNSCREW OUT LS. 38 SPARE

39 SYSTEM FUNCTION 40 SPARE 41 SPARE

42 SPARE 43 SPARE 44 SPARE

45 SPARE 46 SPARE 47 SPARE

48 SPARE 49 SPARE 50 SPARE

51 SPARE 52 SPARE 53 SPARE

54 SPARE 55 SPARE 56 SPARE

57 SPARE 58 SPARE 59 SPARE

Menu 40

F1 F2 F3

F4 F5

F6

F7

F8

F9 F10

00 F 01

03

06

14

24

32

36

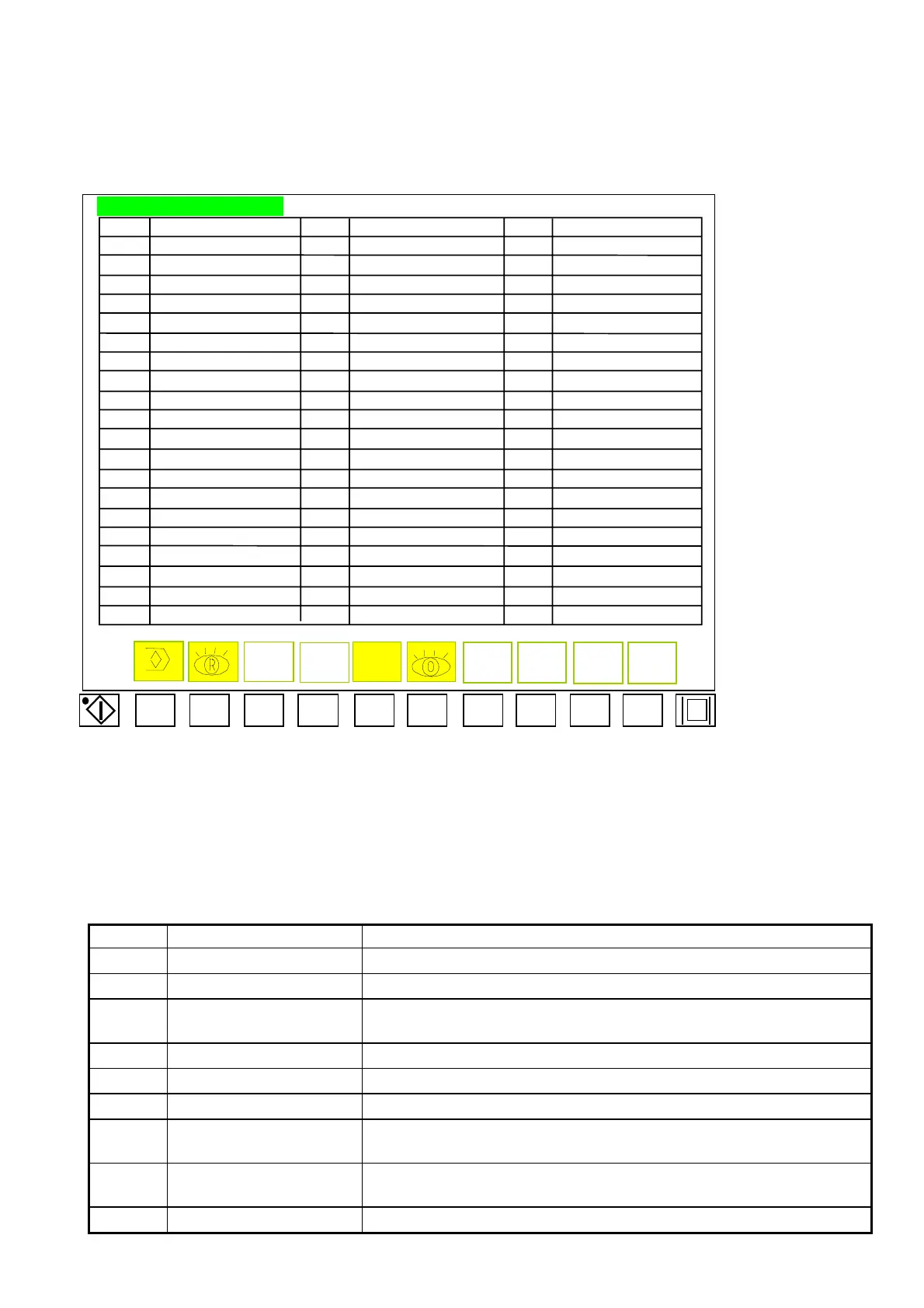

This Menu provides users to check the input signal from outside, when the decode

number turns to red, it means this input signal is(ON). The description is as

follows:

No. Content Description

00

Front Door L.S. Front safety guard closed signal “ON“means closed.

01

Back Door L.S. Rear“ON“ safety guard closed signal “ON“means closed.

02

Save Door Aux L.S Front and back safety guard auxiliary closed signal “OFF“means

closed.

03

Nozzle Contact Carriage forward L.S signal.

04

Min. Mold Th. L.S Mold height adjustment forward L.S signal.

05

Max. Mold Th. L.S Mold height adjustment backward L.S signal.

06

Core 2 In L.S When chosen as core 2 L.S function, used as core 2 in stop

signal .(Optional)

07

Core 2 Out L.S When chosen as core 2 L.S function, used as core 2 out stop signal.

(Optional)

08

Core 1 In L.S When chosen as core 1 L.S function, used as core 1 in stop

04/08/13

105

Loading...

Loading...