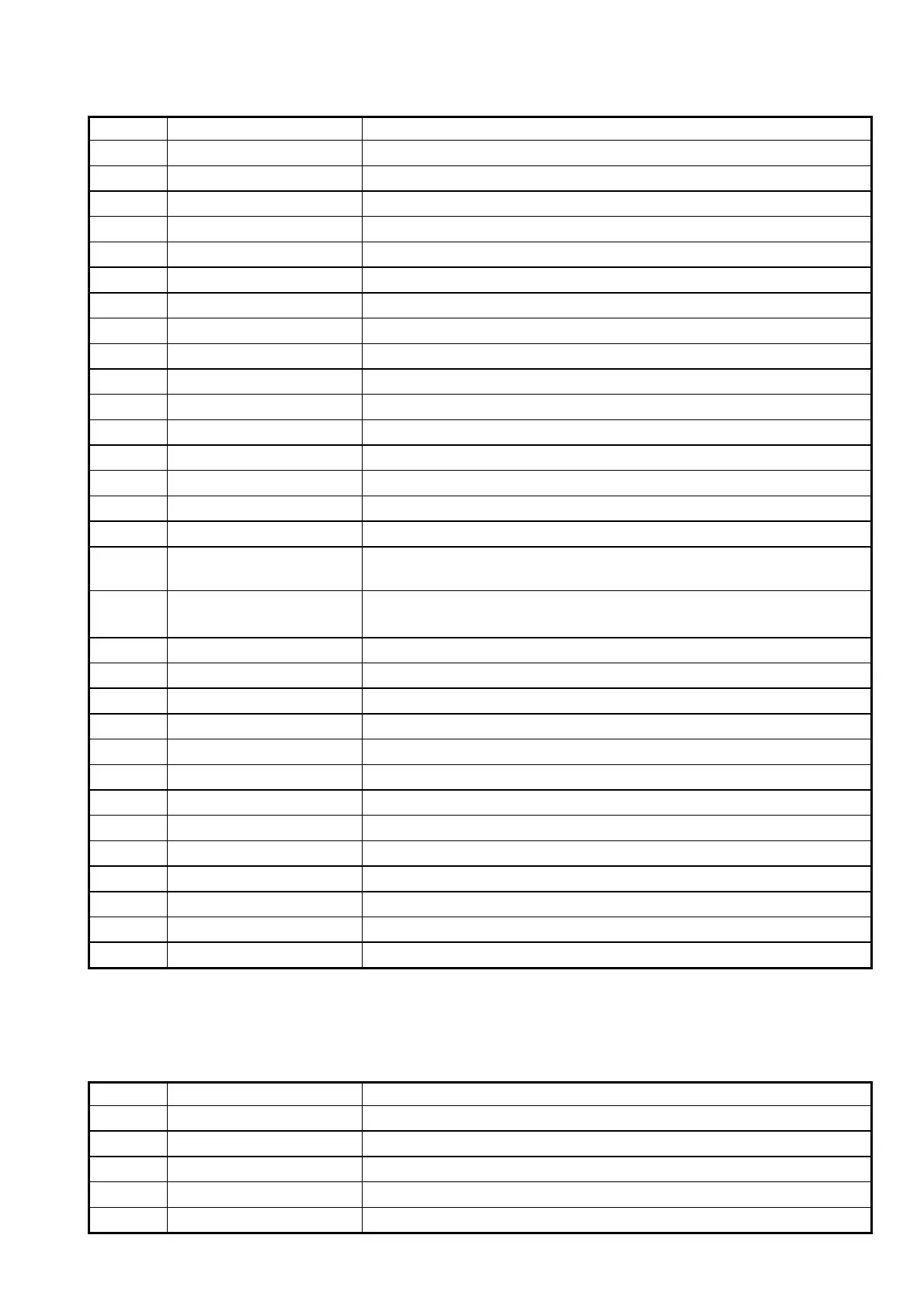

1 Operational Manual

No. Content Description

70

Boozer Clamping Carriage Forward Output

71

Core 1 In

Core 1 In Output。

72

Core 1 Out

Core 1 Out Output。

73

Mold Screw In

Mold Screw Forward Output。(Optional)

74

Mold Screw Out

Mold Screw Backward Output。(Optional)

75

Thinner

Mold Height Adjustment Forward Output。

76

Thicker

Mold Height Adjustment Backward Output。

77

Accum. Pressurized Accumulator Output

78

Accum. Injection Accumulator Assist Injection

79

Accum. Pr. Relief When pneumatic door is decelerating, this output is “ON”.

80

Airblow at End Airblowing Output After Mold Opening

81

Airblow at Opening Airblowing Output After Mold Setting Position

82

Feeding at Opening Plasticizing Output When Opening Mold (Optional)

83

Core 2 In Core 2 In (Optional)

84

Core 2 Out Core 2 Out (Optional)

85

Pos. Cylinder Forward When completion of injection at auto mode, this output will “ON”.

86

Pos. Cylinder Backward Output signal for robot to take part out, when mold opened, this

output will “ON”.

87

Boost

When purchasing DSor double pump, this is aux. Flow rate

output.

88

Lock-Up Close Lock-Up Close Output

89

Lock-Up Open Lock-Up Open Output

90

Clamp Cyl. Close Output Node of High Pressure Cylinder for Mold-Closing.

91

System Used System saving confirmation output.

92

Blank

93

Blank

94

Blank

95

Blank

96

Blank

97

Blank

98

Blank

99

Blank

100

Blank

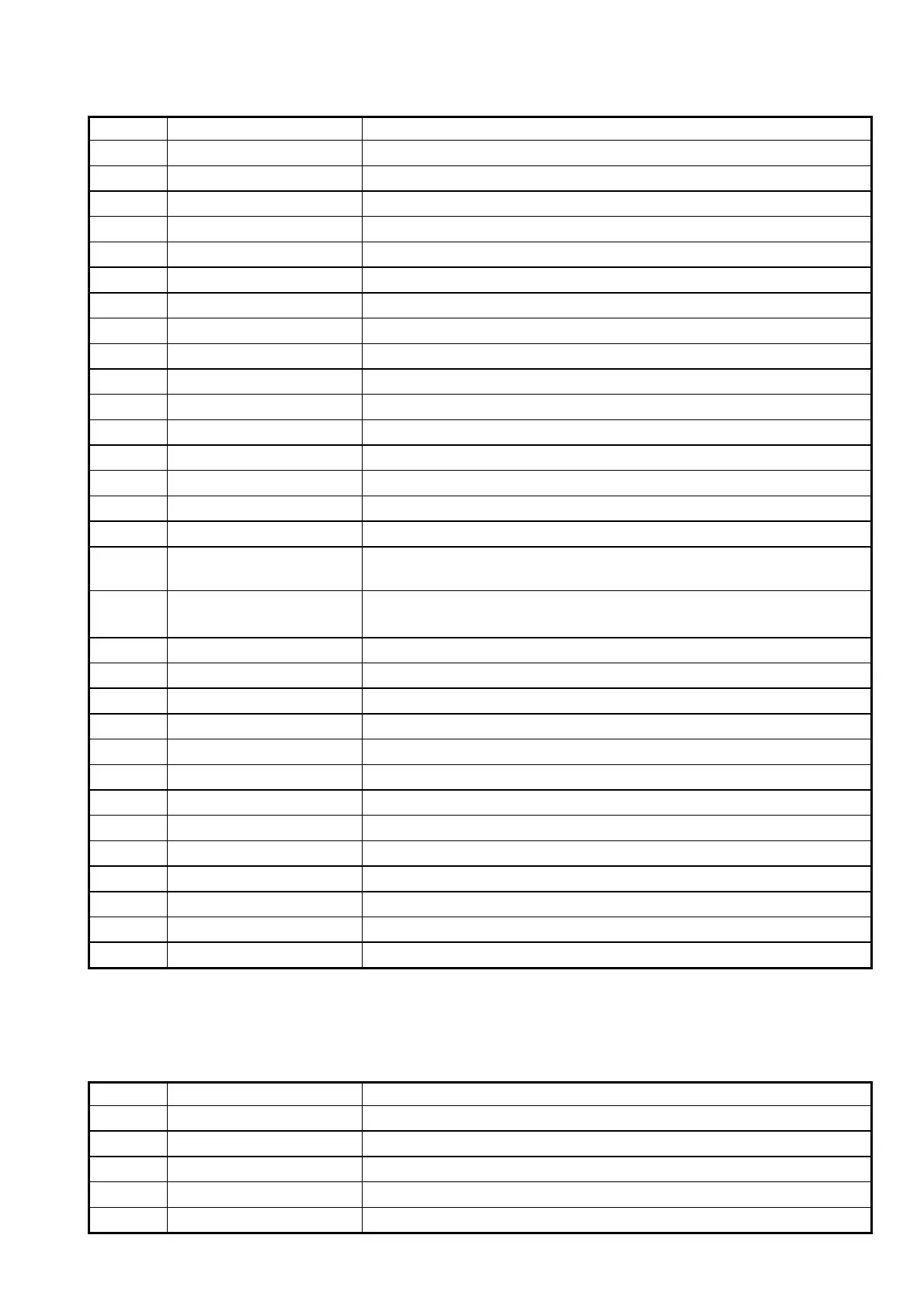

No. Content Description

101

Blank

102

Blank

103

Blank

104

Blank

105

Blank

04/08/13

127

Loading...

Loading...