WS2H and WS3 Manual Page 55

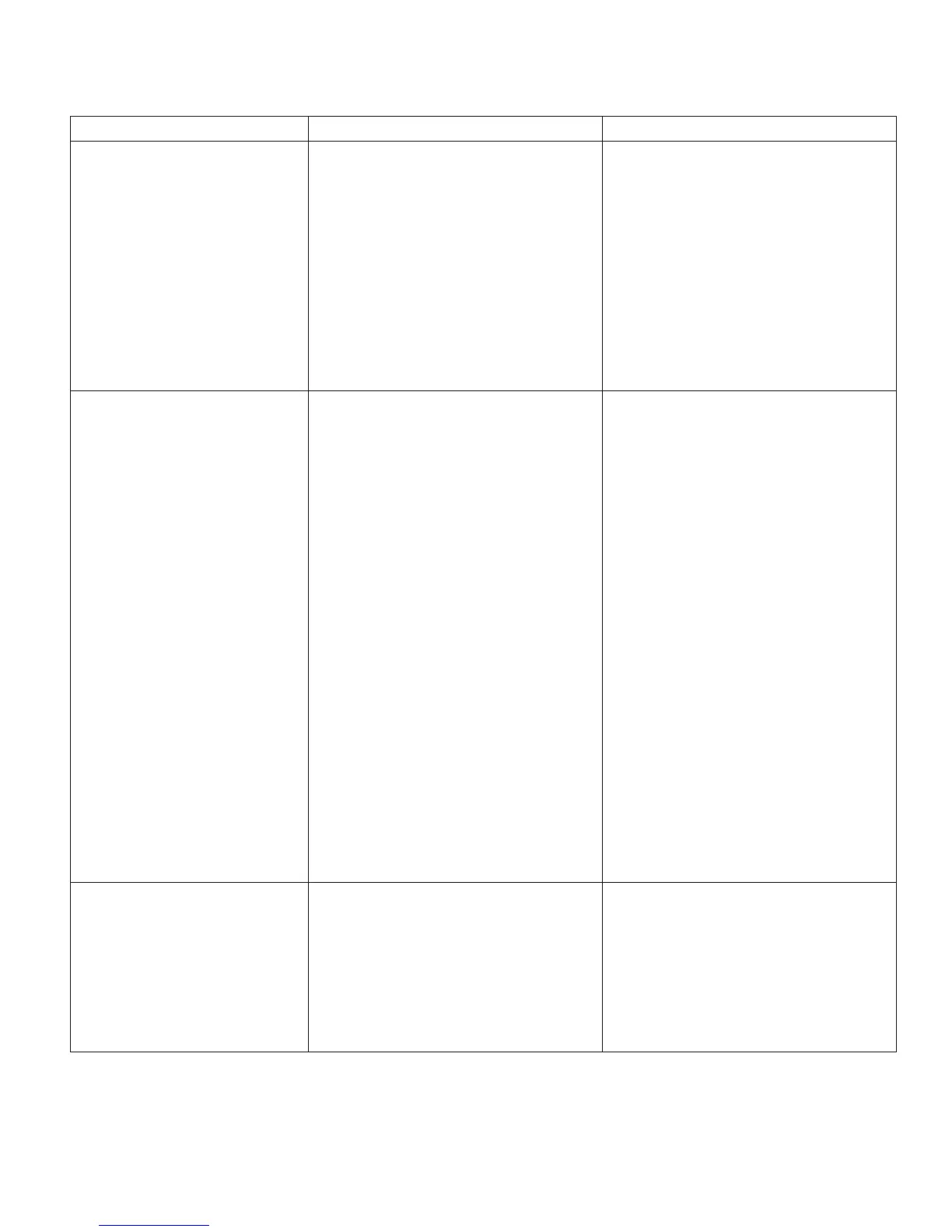

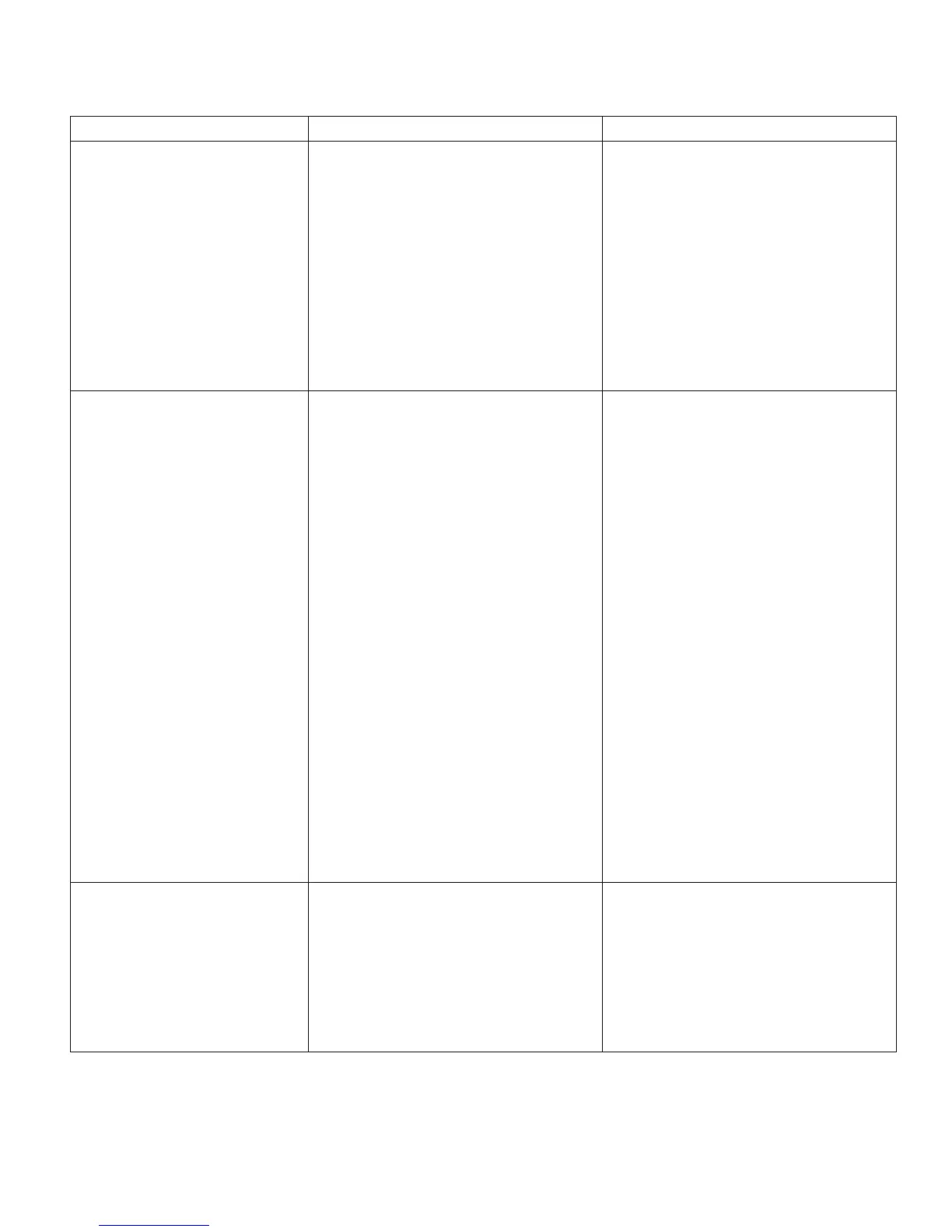

Problem Possible Cause Solution

7. Control valve does not

regenerate automatically

but does when the REGEN

button is depressed and

held.

a. Bypass/ isolation valves in bypass

position

b. Meter is not connected to meter

connection on PC Board

c. Restricted/ stalled meter turbine

d. Incorrect programming

e. Meter wire not installed securely into

three pin connector

f. Defective meter

g. Defective PC Board

a. Turn bypass/ isolation valves handles

to place in service position

b. Connect meter to three pin

connection labeled FLOW on PC

Board

c. Remove meter and check for rotation

or foreign material

d. Check for programming error

e. Verify meter cable wires are installed

securely into three pin connector

labeled FLOW

f. Replace meter

g. Replace PC Board

8. Hard or untreated water is

being delivered

Check water quality directly at unit

outlet

1. Water quality is good

a) Bypass/ isolation valves are open

or faulty

2. Water quality is poor

a) Damaged seal/stack assembly

b) Faulty riser tube or seal

c) Control valve body type and piston

type mix matched

3. Media is exhausted, water quality is

poor

a) Higher than anticipated water

usage

b) Meter not registering

c) No regenerant or low level of

regenerant in regenerant tank

d) Control fails to draw in regenerant

e) Water quality uctuation

f) Fouled media bed

1. External Bypass Leak

a) Fully close bypass/ isolation valves

or replace

2. Internal Bypass Leak

a) Replace seal/stack assembly

b) Verify seal placement &

engagement with riser

c) Verify proper control valve body

type and piston type match

3. No internal leaks

a) Check program settings or

diagnostics for abnormal water

usage

b) See Troubleshooting Guide #3

c) Check refill setting in programming.

Check refill flow control for

restrictions or debris and clean or

replace, check refill flow control rate

for proper fill time.

d) Refer to Troubleshooting Guide # 12

e) Test water and adjust program

values accordingly

f) Replace media bed

9. Control valve uses too much

regenerant

a. Improper re ll setting or re ll ll ow

control is not sized properly

b. Improper program settings

c. Control valve regenerates frequently

a. Check re ll setting and check re ll

ow control for proper re ll rate.

b. Check program setting to make sure

they are speci c to the water quality

and application needs

c. Check for leaking xtures that may

be exhausting capacity or system is

undersized

WS2H/ WS3 TROUBLE SHOOTING GUIDE (CONTINUED)

Loading...

Loading...