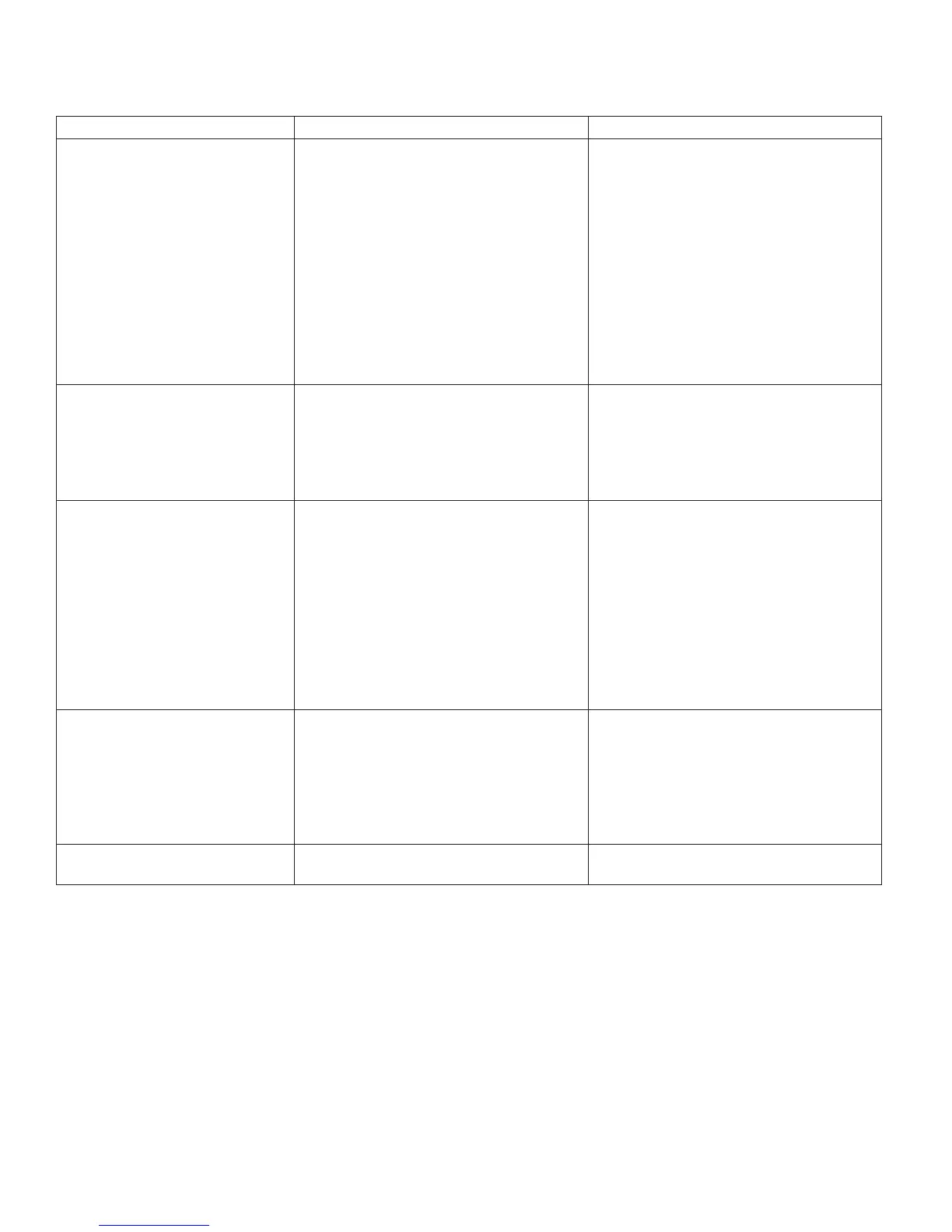

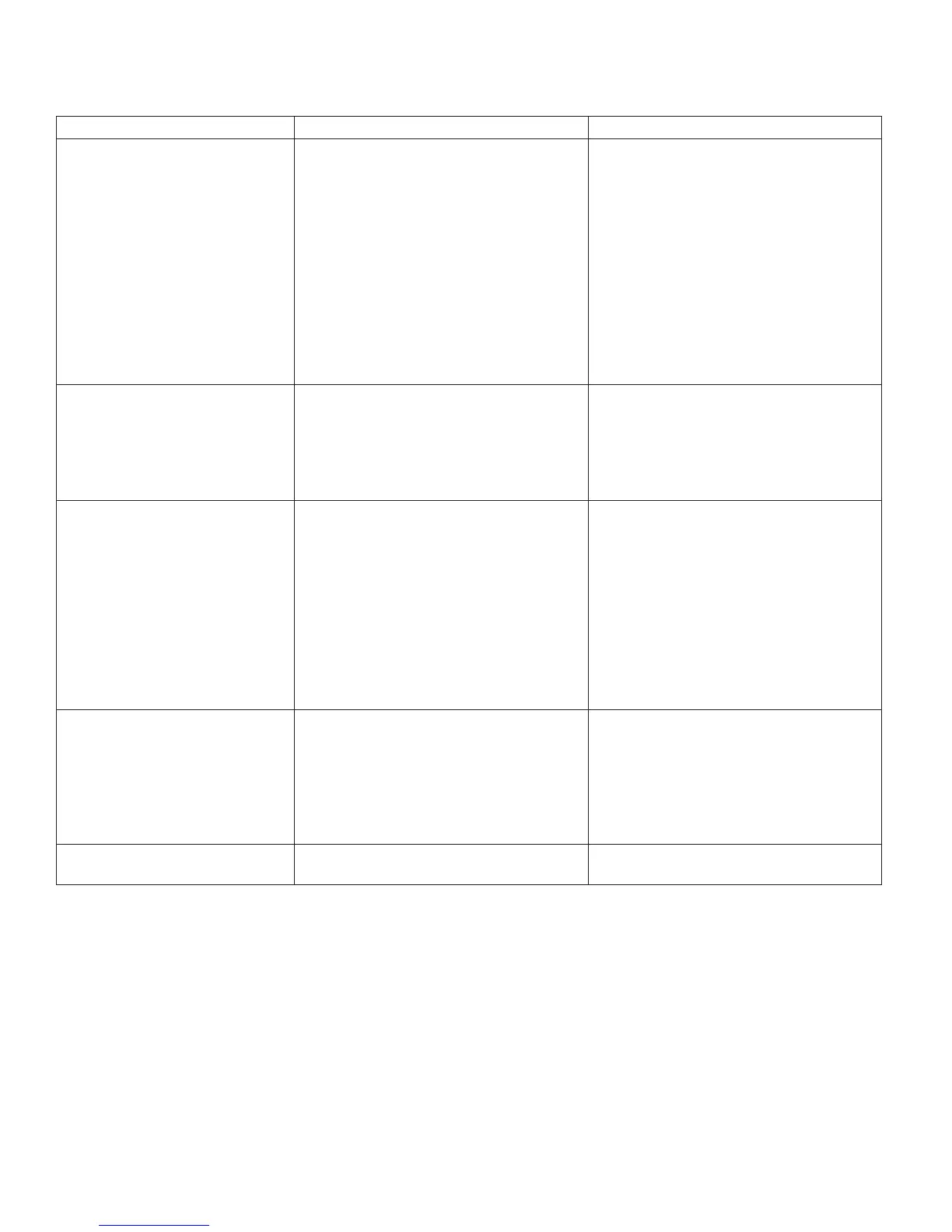

Page 56 WS2H and WS3 Manual

Problem Possible Cause Solution

10. Residual regenerant being

delivered to service

a. Low water pressure

b. Plugged, fouled, or incorrect injector

size

c. Restricted drain line

d. Damaged seal/ stack assembly or

piston allowing leakage during draw

e. Draw time too short

f. Excessive re ll

g. Vacuum leak in draw line / elbow

a. Check incoming water pressure

– water pressure must remain at

minimum of 25 psi

b. Inspect and clean or replace injector,

or replace injector

with correct size

for the application

c. Check drain line for restrictions or

debris and clean

d. Check seal/ stack assembly and

piston for damage and replace

e. Program proper draw time needed

f. Program proper re ll time needed

g. Locate vacuum leak and x

11. Excessive water in

regenerant tank

1. Tank is being over lled

a) Improper program settings

b) Missing re ll ow controller

2. Previous regenerant is not being

drawn out

1. Excess from ll cycle

a) Verify program settings

b) Visual inspection / measure volume

output into container

2. See Troubleshooting Guide #12

12. Control valve fails to draw in

regenerant

a. Injector is plugged

b. Faulty regenerant piston

c. Regenerant line connection leak

d. Drain line restriction or debris cause

excess back pressure

e. Drain line too long or too high

f. Low water pressure

g. Damaged seal/ stack assembly

a. Remove injector and clean or replace

b. Replace regenerant piston

c. Inspect regenerant line for air leak

d. Inspect drain line and clean to correct

restriction

e. Shorten length and/or height

f. Check incoming water pressure

– water pressure must remain at

minimum of 25 psi

g. Inspect seal stack assembly for

damage and replace

13. Water running to drain

a. Power outage during regeneration or

unit is currently in regeneration

b. Damaged seal/ stack assembly

c. Piston assembly failure

d. Drive cap assembly not tightened

properly

a. Upon power being restored control

will nish the remaining regeneration

time. Reset time of day.

b. Replace seal/ stack assembly

c. Replace piston assembly

d. Re-tighten the drive cap assembly

14. Motor drives intermittently

during regeneration.

a. Low power a. See Table 2 Software and Power

Supply Compatibility

WS2H/ WS3 TROUBLE SHOOTING GUIDE (CONTINUED)

Loading...

Loading...