7 Troubleshooting

48 / 80 GB October 2013

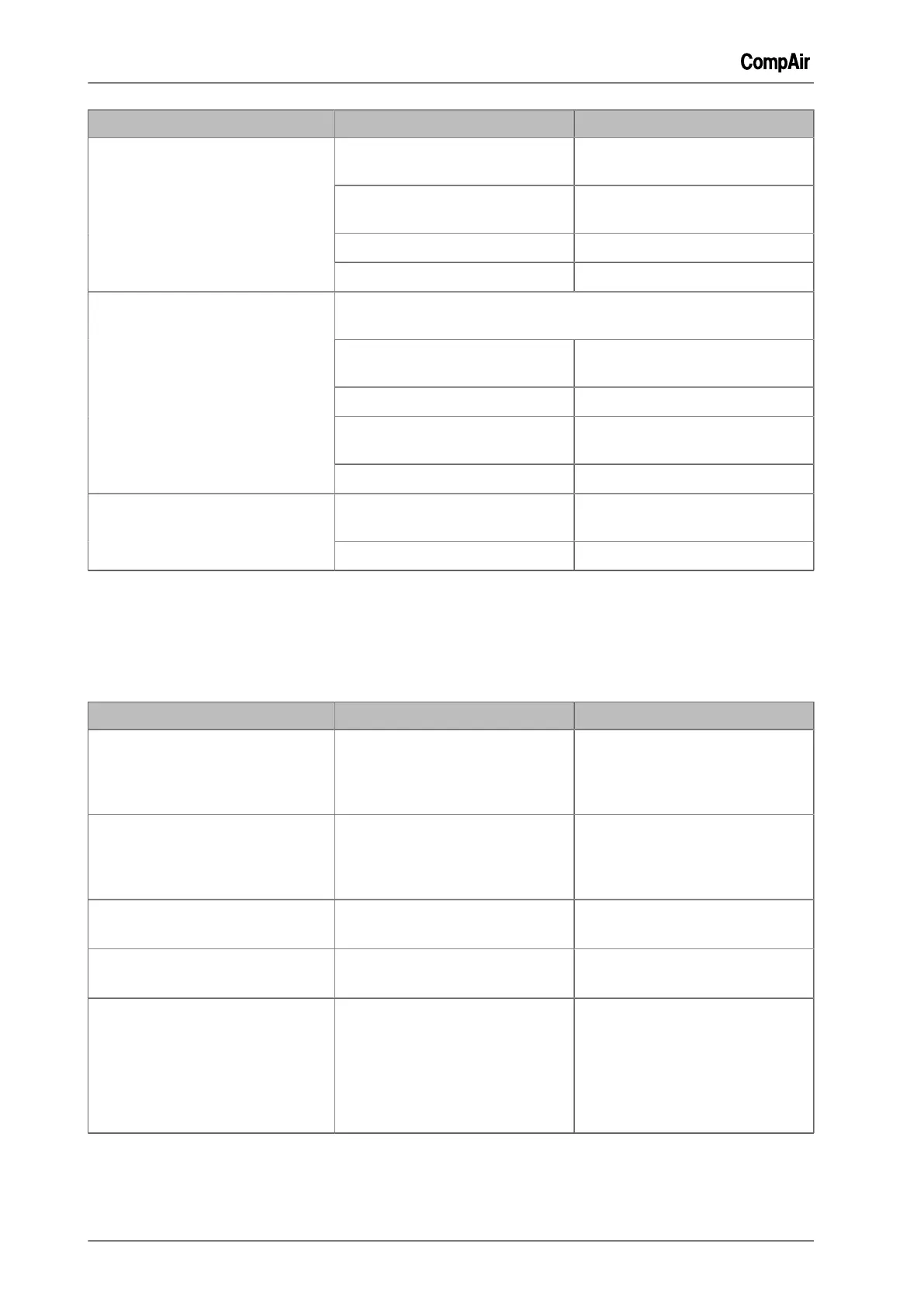

Display Possible Cause Remedy

Solenoid valve for water outlet

faulty.

Check.

Dirt trap in front of solenoid valve

dirty.

Check dirt trap.

Outlet ball valve closed? Open ball valve.

Faulty water level sensor B10. Check level sensor and wiring.

Recurring error during water change in intake stage (warning A628

already activated):

Poor supply of water for machine,

water pressure may be too low.

Check water pressure.

Water treatment unit faulty. Check.

Solenoid valve for water inlet

faulty.

Check.

E421:

Water change supply

Faulty water level sensor B10. Check level sensor and wiring.

Incorrect phase sequence. Check phase sequence and cor-

rect if necessary.

E422:

Phase monitoring

Loss of one or more phases. Check the power supply.

Chart 7-3: Faults triggered by the compressor (E400 - E495) (RS)

1)

System specific setting. See "Factory Settings" menu.

3) Monitoring through optional device/sensor connected to a programmable digital input. See chap-

ter "Programmable Inputs" and wiring diagram.

Faults triggered by the frequency converter (VSD) (E500 - E531) (RS)

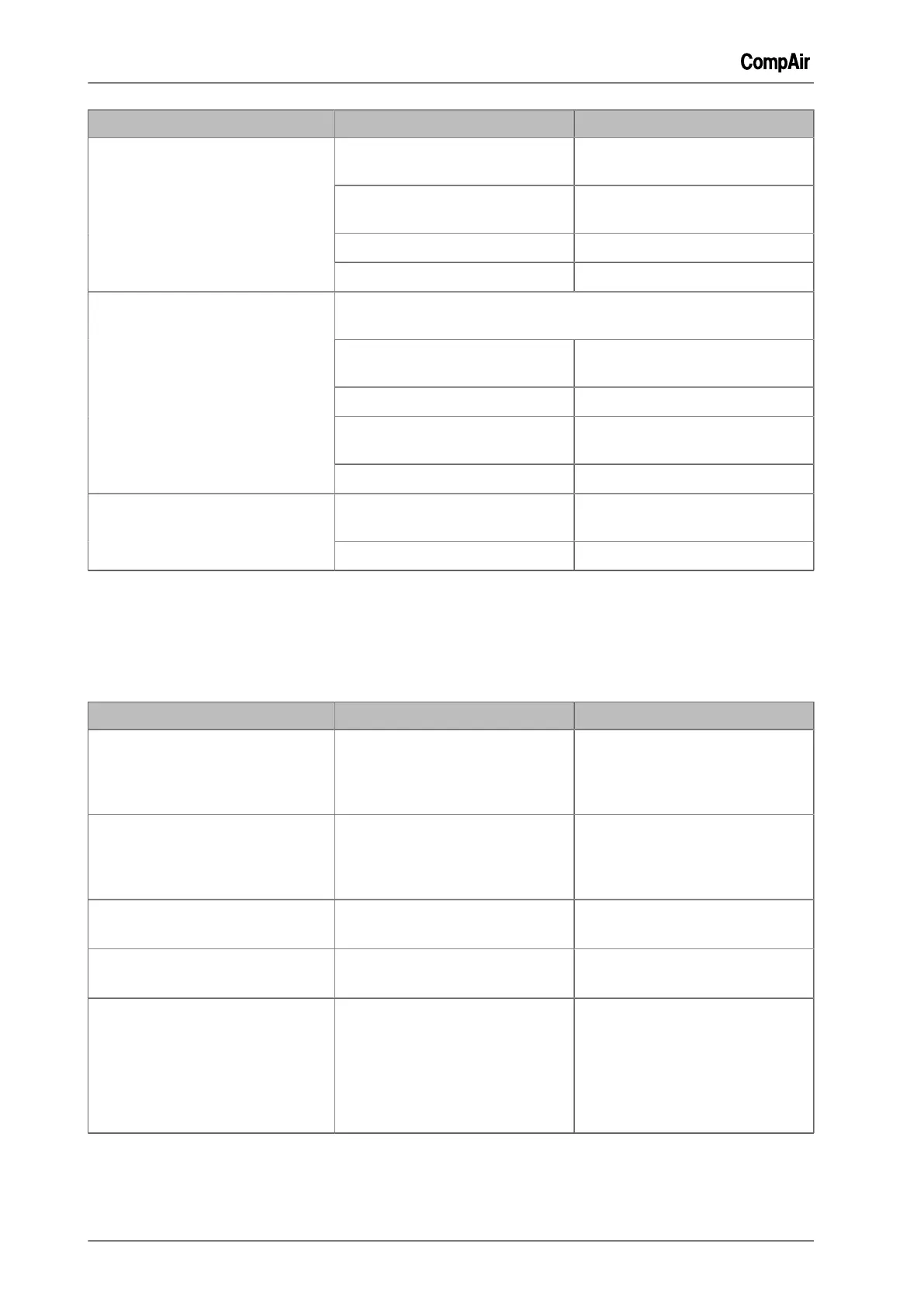

Display Possible Cause Remedy

E500:

Pre-Adjustment VSD

The VSD was faulty or not

programmed (replacement

device), so that it had to be repro-

grammed by the DELCOS XL.

E501:

Pre-Adjustment

The VSD was faulty or not

programmed (replacement

device), so that it had to be repro-

grammed by the DELCOS XL.

E502:

VSD Locked

Error during programming of the

VSD.

Contact Gardner Denver Service.

E503:

VSD Write Fault

Error during programming of the

VSD.

Contact Gardner Denver Service.

E504:

VSD Communication

Communication with the VSD

interrupted, VSD does not

respond.

Main contactor (Compressors

with PowerFlex 400 VSD only)

Check the Modbus interface

wiring.

If no fault is found, contact

Gardner Denver Service.

Chart 7-4: Faults triggered by the frequency converter (VSD) (E500 - E531) (RS)

Loading...

Loading...