10 Base Load Sequencing (BLS)

68 / 80 GB October 2013

In the event of a line pressure sensor fault (Fault

E406:Sensor B1 (Line Press.)), the master can no

longer control the group and shuts off the BLS

until the fault is removed and reset. If the master

compressor shuts down because of a fault other

than a line pressure sensor fault, or if it is shut

down manually, the master will continue to con-

trol the base load sequencing with the remaining

slaves.

Once the line pressure exceeds the defined maxi-

mum line pressure, the compressor at the far right

in the sequence will be shut down. As long as the

maximum line pressure is exceeded, the system

will continue to shut down further compressors

consecutively in short time intervals.

If the line pressure drops below the defined mini-

mum line pressure, the next available compressor

will be started up immediately, followed by more

compressors in a set period of time ("Start delay")

if the line pressure remains low.

RS-Master - FS-Slaves: The speed-controlled

compressor regulates the line pressure within the

available speed range, to be exactly between the

minimum and the maximum line pressure. If the

pressure band limits are reached, compressors

are started up and shut down as described above.

RS-Master - RS-Slaves: Speed-regulated com-

pressors will run approximately at the same rota-

tional speed and load if their size is approximately

the same. After a manual restart of a compressor

(e.g. after service), the speed may be temporar-

ily asynchronous until the compressor achieves its

minimum or maximum speed limit.

Specification of a new Sequence based on

hours run (BLS)

Once the transfer interval period has elapsed, the

BLS master establishes a new sequence order on

the basis of the Operating hours (BLS) of the com-

pressors. The compressor with the lowest Operat-

ing hours (BLS) is placed in first position in the se-

quence and so on.

RS-Master - FS-Slaves: The speed-regulated

compressor will always stay in first position,

whereas the fixed-speed slaves will have their se-

quence order changed periodically.

The freely adjustable Operating hours (BLS) coun-

ters can be used to manipulate the sequence if

necessary, for example if a new compressor is in-

stalled alongside older ones. See the following ex-

amples.

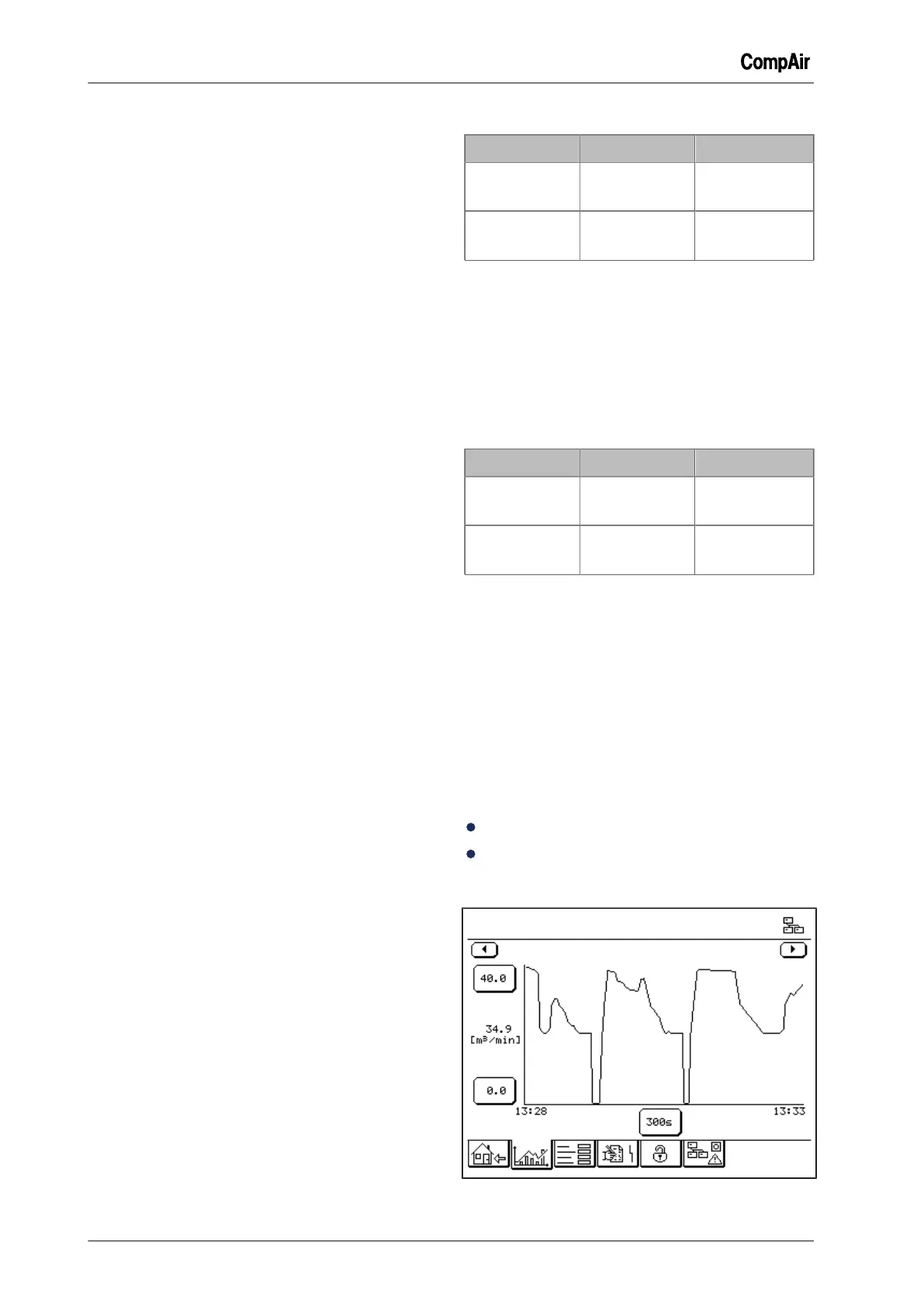

Example 1

Compressor 1 Compressor 2

Hours Run

(actual)

1000 h 1 h

Operating

hours (BLS)

1000 h 1h

Chart 10-7: Example 1

Operating hours (BLS) are set to the same figure

as the actual operating hours. The new Compres-

sor 2 will run in the base load position for about

1000 h, as it has the lowest Operating hours

(BLS). Afterwards, both compressors alternate in

sequence.

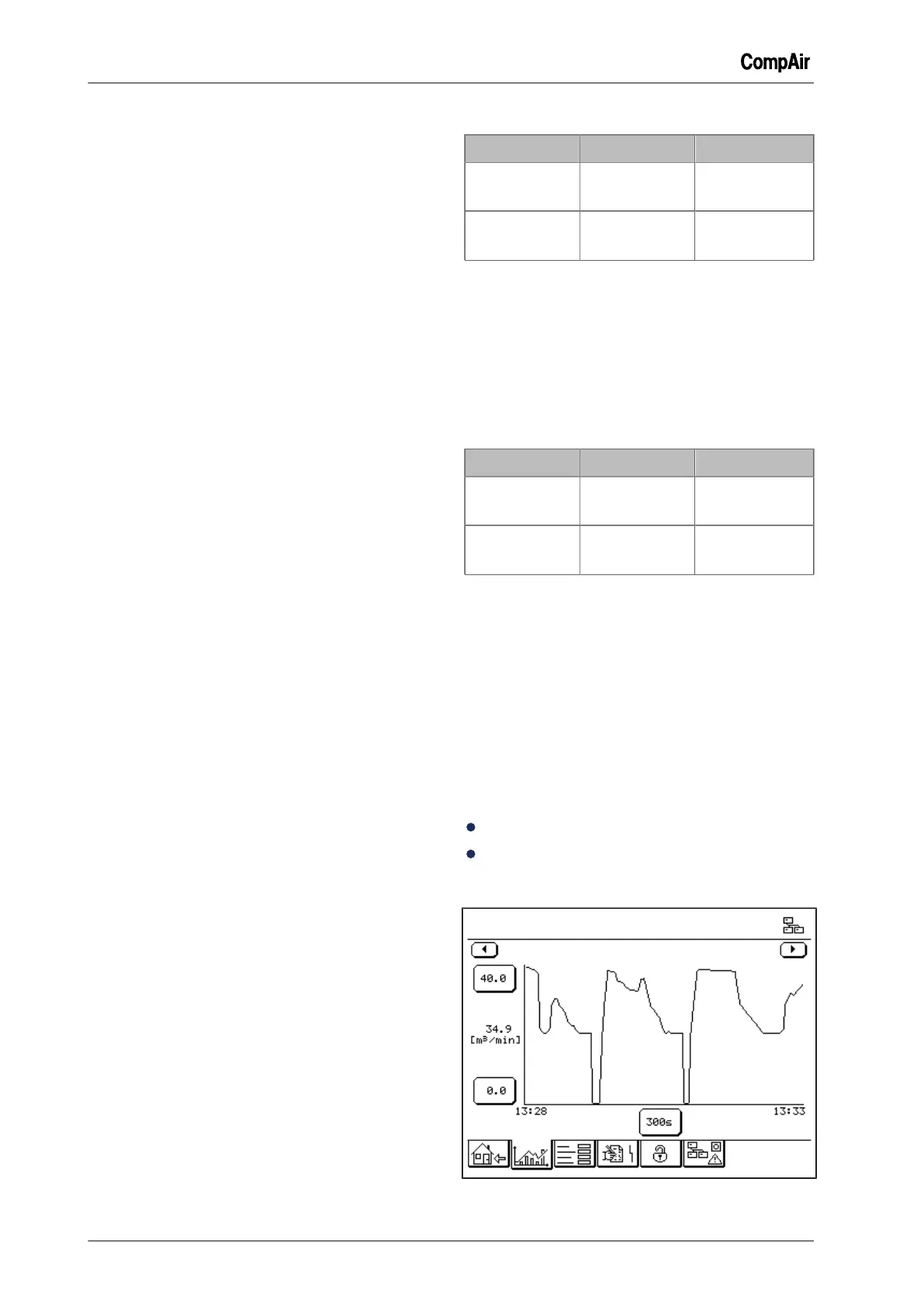

Example 2

Compressor 1 Compressor 2

Hours Run

(actual)

1000 h 1 h

Operating

hours (BLS)

1000 h 1000 h

Chart 10-8: Example 2

The Operating hours (BLS) were modified to inte-

grate Compressor 2 and the alternating sequence

for the two compressors starts immediately.

10.8 Trend and statistics graphs

Additional graphs when base load sequenc-

ing is activated

If base load sequencing is activated, the follow-

ing graph screens are additionally available in the

menu "Trends":

Volume Flow (BLS)

Statistics Weekly Profile (BLS)

Volume Flow (BLS)

Fig. 10-13: Graph screen "Volume Flow (BLS)"

Loading...

Loading...