P

REVENTATIVE

MAINTENANCE

SCHEDULE

CONTINUED

UGE048/1103 CSC Combination Puller/Cutter

M

AINTENANCE 5-5

● Semi-annual (every six months)

❒❒

Inspecting electrical terminals

Check all electrical terminals for tightness; adjust as

needed. See Checking Electrical Connections, Section

5.

❒❒

Checking torque on Trantorque coupling device

Check the tightness (torque) of the Trantorque cou-

pling device with a torque gauge. This device connects

the cutter head to the Micron reducer shaft. See

Checking Torque, Section 5.

❒❒

Checking all electrical cables

Inspect all electrical cables for cuts and abrasions.

Replace as needed. See Checking Electrical

Connections, Section 5.

❒❒

Inspecting control panel lights

Check to make sure no LEDs or lights are burned out

on the control panel. Replace as needed.

❒❒

Checking motor brushes

Inspect the motor bushes. Replace as needed. See

Replacing Motor Brushes, Section 5.

● Monthly

❒❒

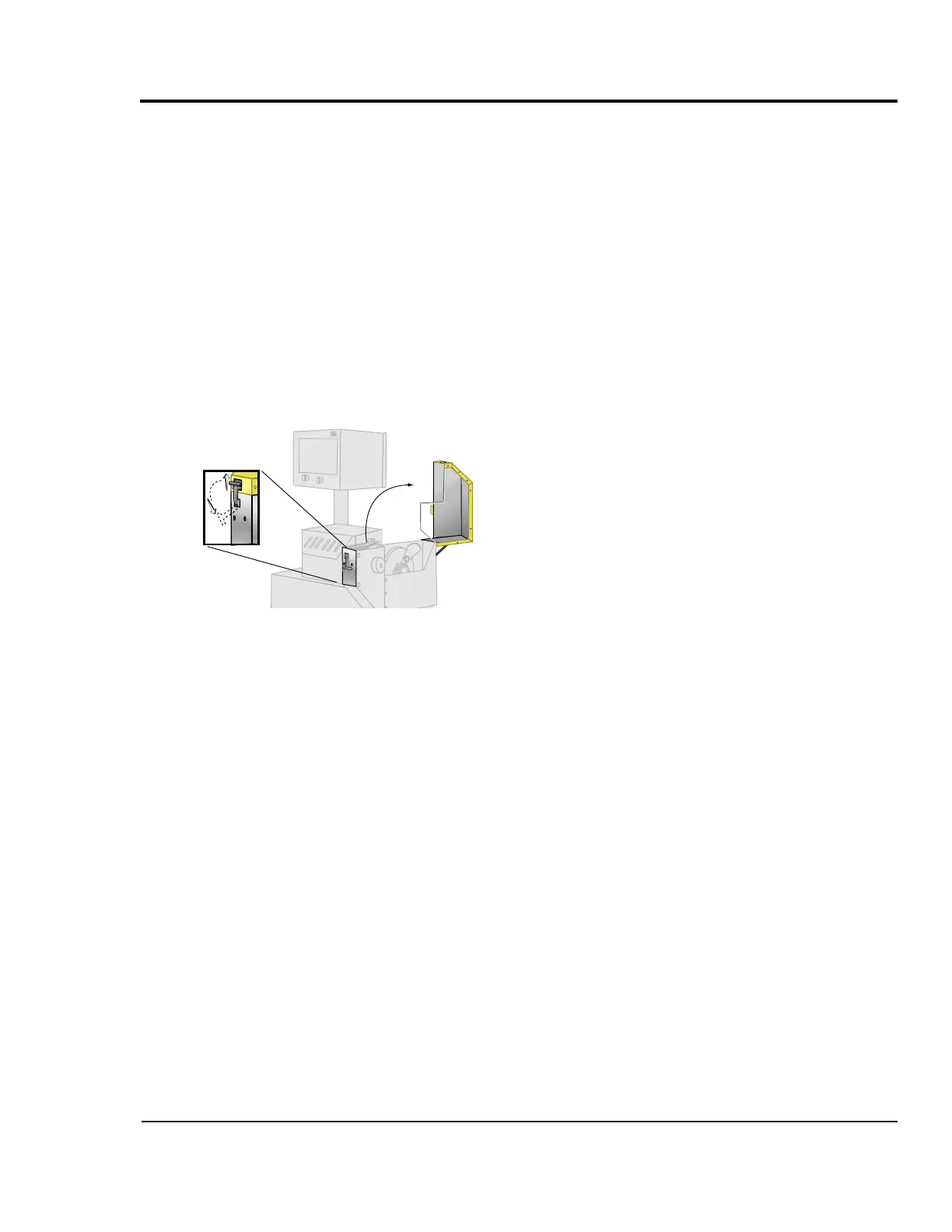

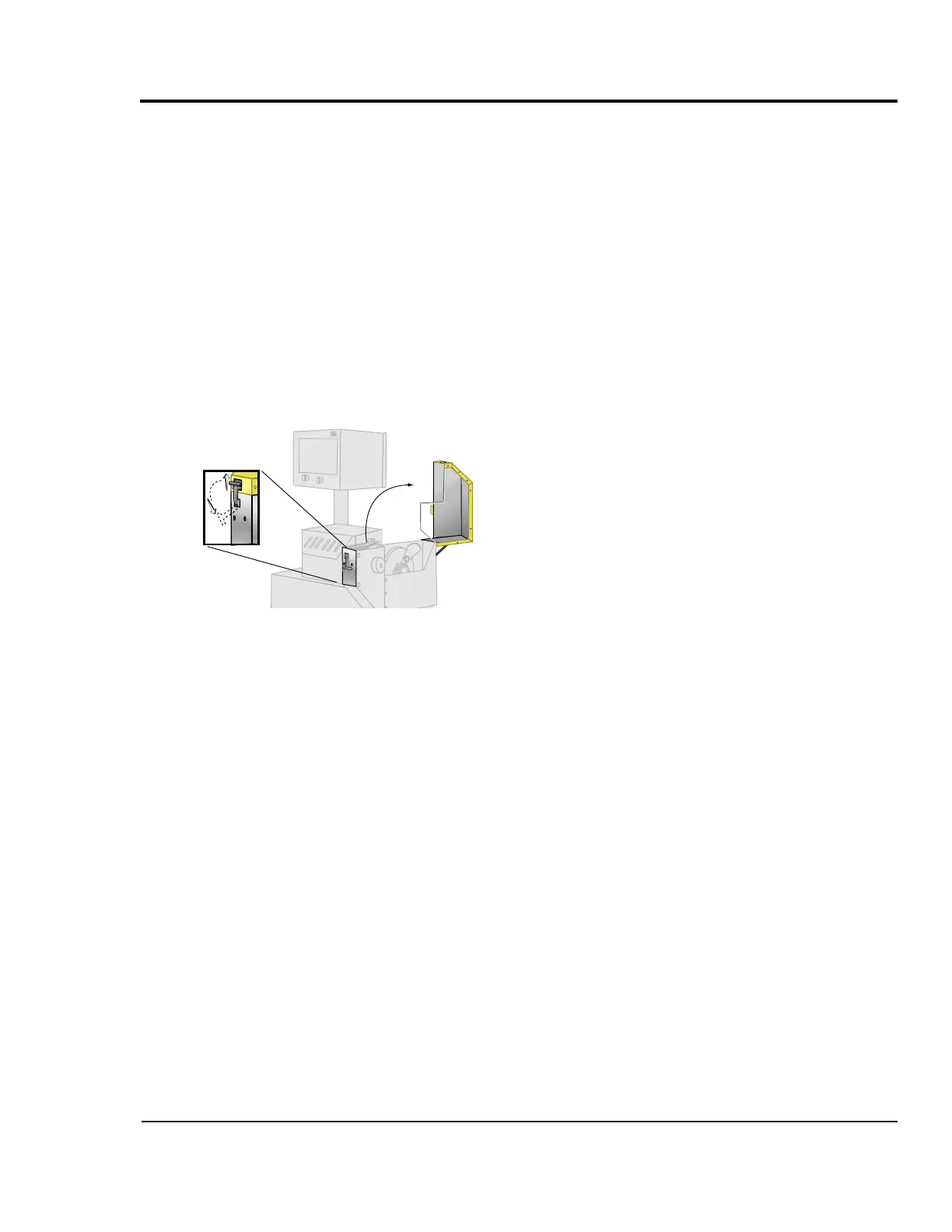

Checking hardware on the knife guard

Inspect the hardware on the knife guard (fasteners on

hinge and the clear blade guard window). Tighten as

needed.

❒❒

Checking bushing holder proximity switches

Inspect the proximity switch set screws. Adjust as

needed. See Adjusting the Cutter Proximity Switches,

Section 5.

❒❒

Cleaning the clear blade guard window

Clean using glass cleaner or plain water. Other materi-

als may cause premature loss of clarity or crazing.

❒❒

Checking the metal draw latch

Inspect the latch on knife guard for wear and proper

tension. Readjust or replace as needed.

Loading...

Loading...