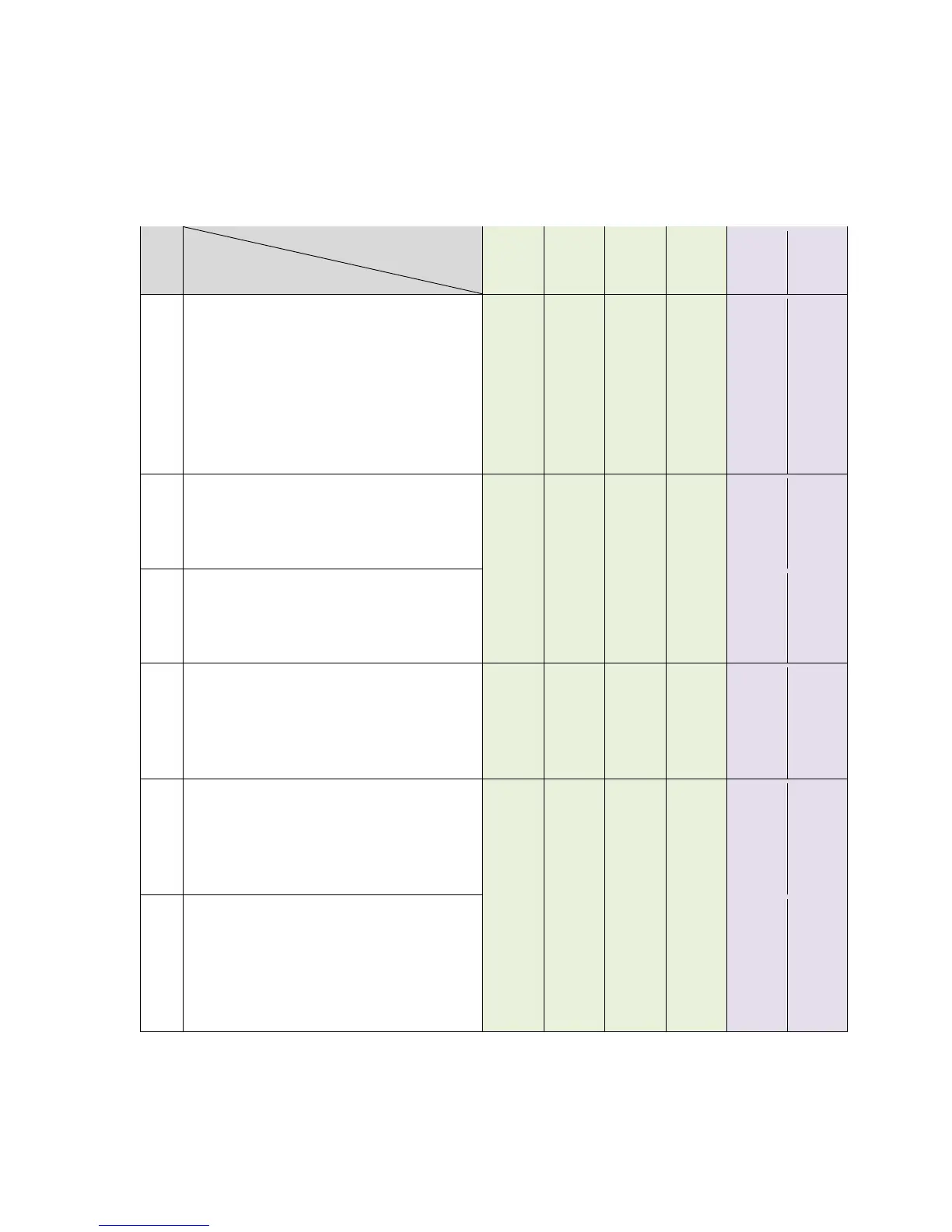

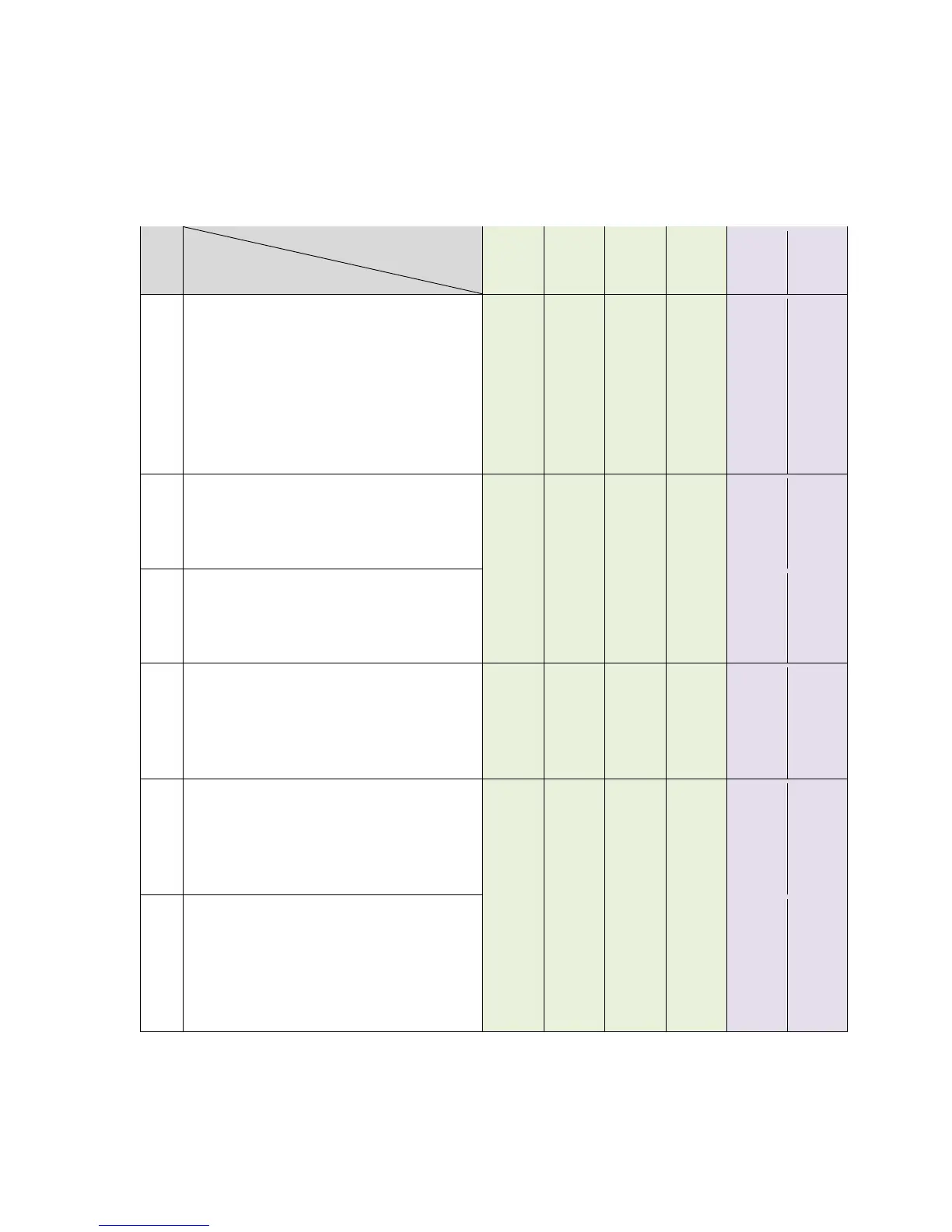

1 Painted, coated & bare metals.

Coatings up to 20mm (3/4in)

thick

2

.

Corrosion: non to moderate.

Thickness: 3 to 250mm (1/8in

to 10in)

1

.

Class Shipping Surveys.

General purpose use.

√

2 Painted & bare metals.

Corrosion: non to moderate.

Thickness: 2 to 150mm (0.1in

to 6in)

1

.

√

3 Painted & bare metals.

Corrosion: non to light.

Thickness: 1 to 50mm (0.05in

to 2in)

1

.

√

4 Small diameter pipes.

Boiler tubes.

Corrosion: non to light.

Thickness: 1 to 25mm (0.05in

to 1in)

1

.

√

5 Uncoated or coated metals

3

.

Corrosion: very heavy, pitting.

Thickness: 2.0 to 100mm

(0.08in to 2in)

1

.

General purpose use.

√

6 Uncoated or coated metals

3

;

Cast Iron. Wrought Iron.

Plastics.

Corrosion: very heavy, pitting.

Thickness: 3.0 to 150mm

(0.12in to 6in)

1

.

√

Loading...

Loading...