measuring cast iron.

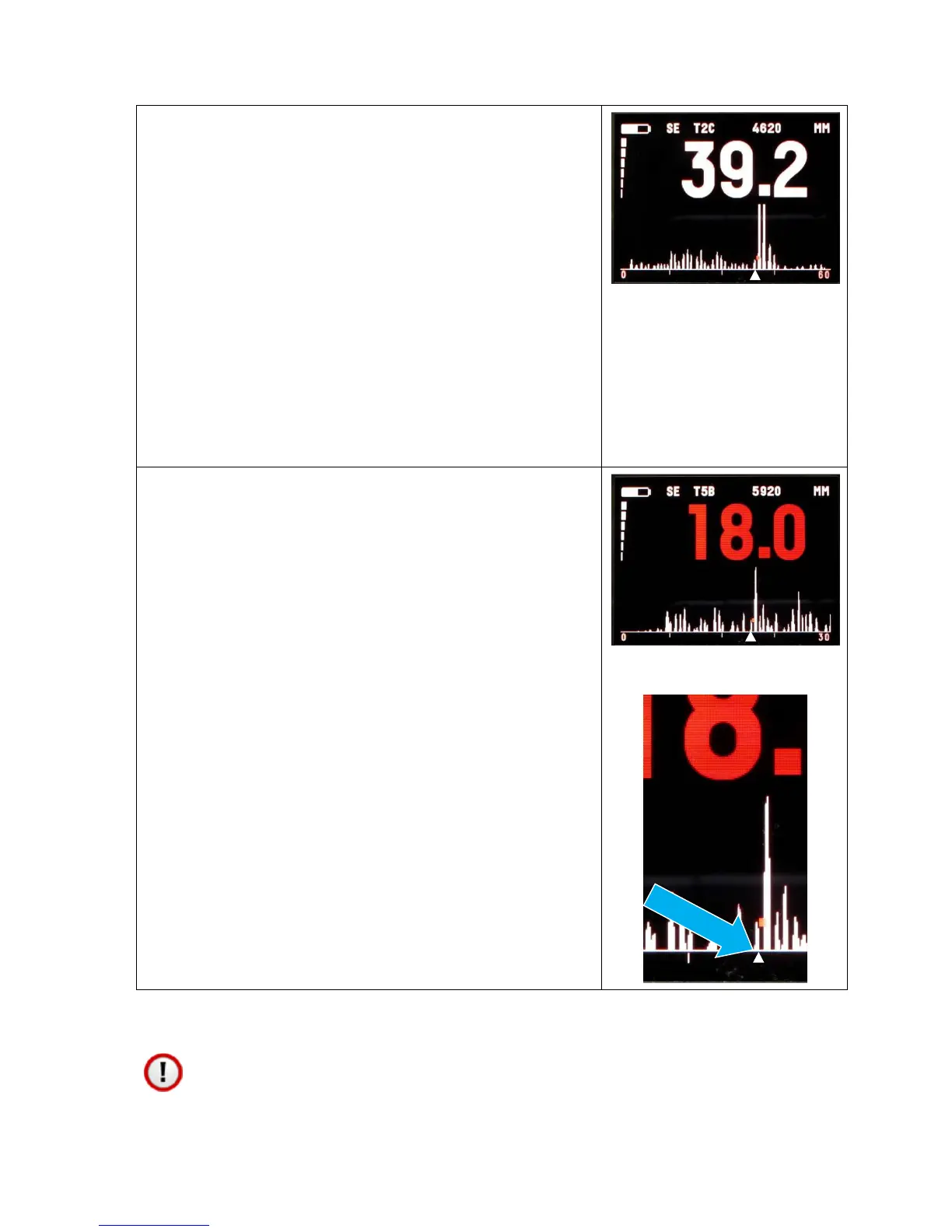

This A-Scan shows a good clear ultrasound

signal with a distinctive back-wall echo.

Even though there are small echoes before

the back-wall peak, the arrow is correctly

placed under the start of the biggest echo

peak.

The measurement value of 39.2 is stable

and yellow in colour.

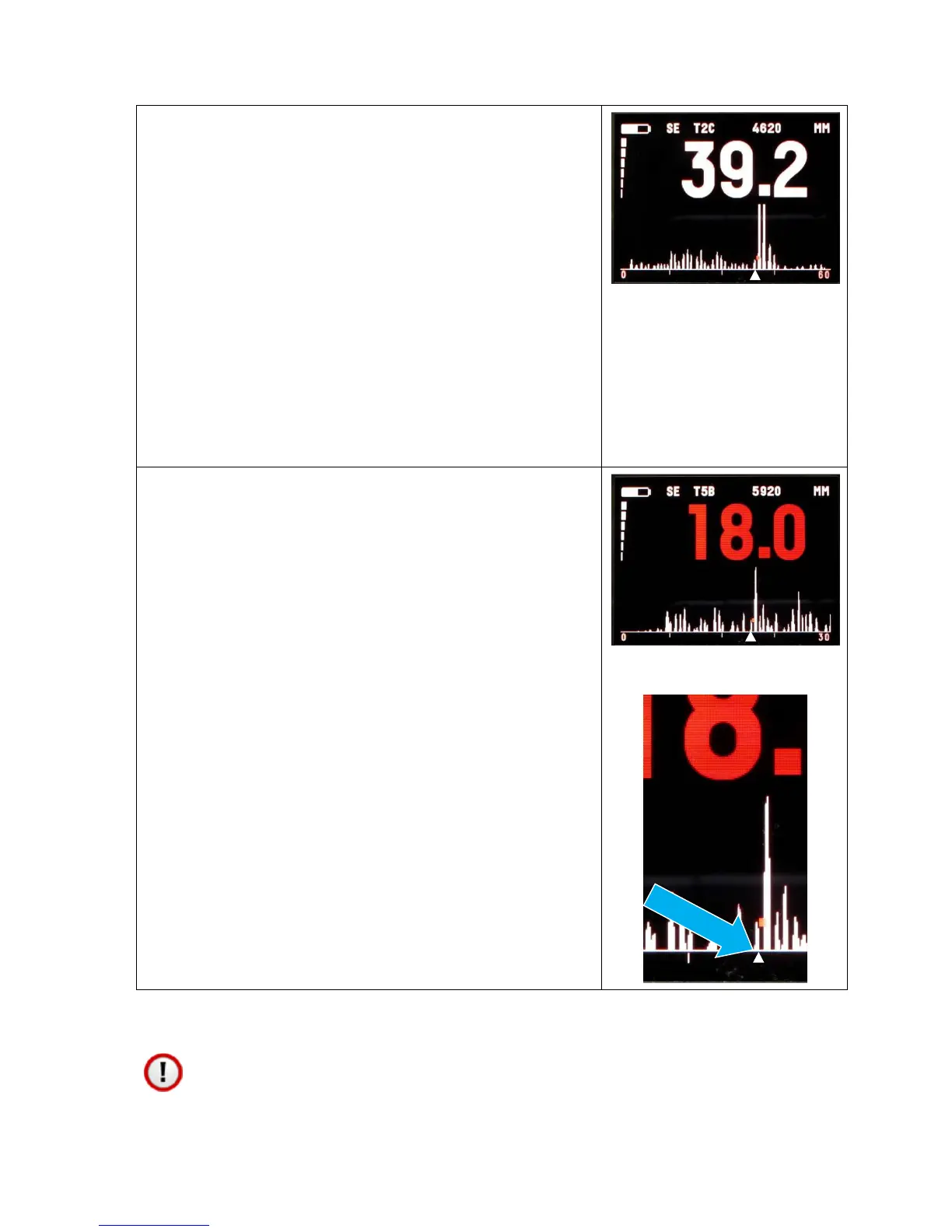

ultrasound signal.

There are lots of echoes and it’s not very

clear which is the correct back-wall echo.

It is probably the biggest peak ¾ of the

way across the A-scan graph – but the

gauge may not detect this.

You can use the A-scan to check that the

gauge has identified the correct peak

which is marked by the arrow.

If it looks right and the arrow is in the

correct position then you can decide to use

the thickness measurement.

If it looks wrong then try another location.

Loading...

Loading...