114 of 132

M-SV-001-EN Rev.E

Maintenance

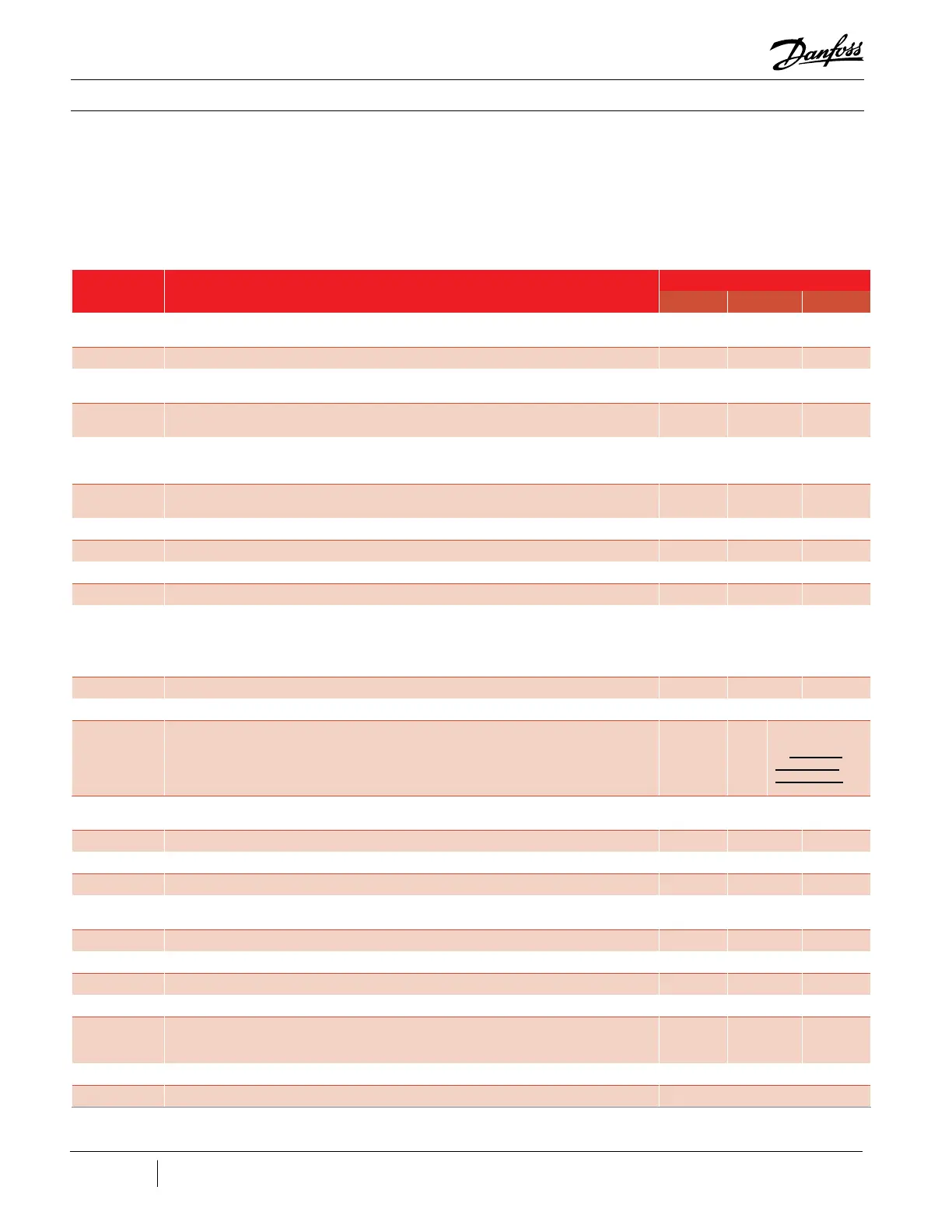

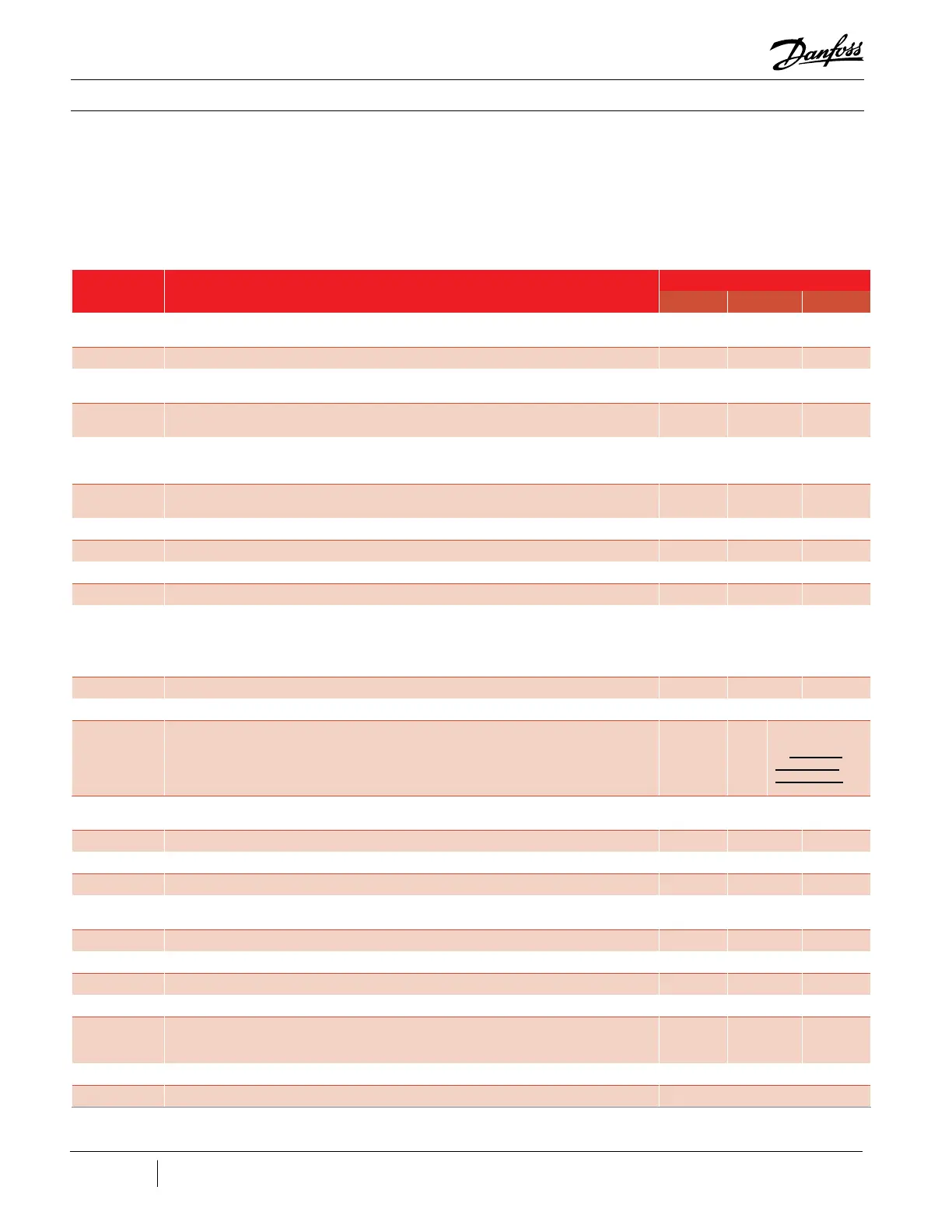

5.1 Preventive

Maintenance Tasks

Table 25 (Preventative Maintenance Tasks) lists

tasks that should be performed on a regular basis

to maintain optimal performance of the system.

Table 25 - Preventive

Maintenance Tasks

Item Task

Frequency

6 Mos 12 Mos Other

General

Inspections

Check physical condition of compressor. √

Check for excessive vibration from other rotating equipment. √

Check for oil in the system. The compressor must operate in an oil-free environment. Ensure all

oil is removed from the system.

√

Compressor

Inspections

Connect to the compressor using the Service Monitoring Tools software and download fault

and event logs. Review and save logs for future reference.

√

Connect to the compressor using the Service Monitoring Tools software and perform a

calibration. Do not save the calibration to EEPROM if the compressor has been operating

correctly. Create and save a Calibration Report for future reference.

√

Electrical

Inspections

Check main power supply voltages. √

Ensure electrical terminals are tight. √

Check for signs of hot spots/discoloration on power cables. √

Check amperages during operation are as per design. √

Check DC bus voltage. √

Replace DC Capacitor Assembly.

Energized:

10 years

De-

energized:

5 years

Check operation of all system safety devices and interlocks. √

Perform moisture-prevention measures. √

Replace Soft Start fan.

5 Years, Refer

to Customer

Notification

B-CN-041-EN

Electronic

Inspections

Ensure all communication cables are secure. √

Ensure all electronic modules are secure. √

Check physical condition of all exposed printed circuit boards (PCBs). √

Check all exposed PCBs for dust build-up and clean if necessary. √

Check discharge and suction pressure/temperature sensors for accuracy against calibrated

pressure/temperature gauges.

√

Refrigeration Check operation of IGV assembly. √

Check system refrigeration charge. √

Check superheat/level control, if applicable. √

Check system and motor-cooling liquid line to ensure sufficient sub-cooling. √

Verify discharge check valve operation.

If there is backward gas flow immediately after stopping the compressor, replace the check

valve.

√

Check operating conditions external to the compressor. √

Inspect/clean motor-cooling strainer (if service has taken place). As required

Loading...

Loading...