124 of 132

M-SV-001-EN Rev.E

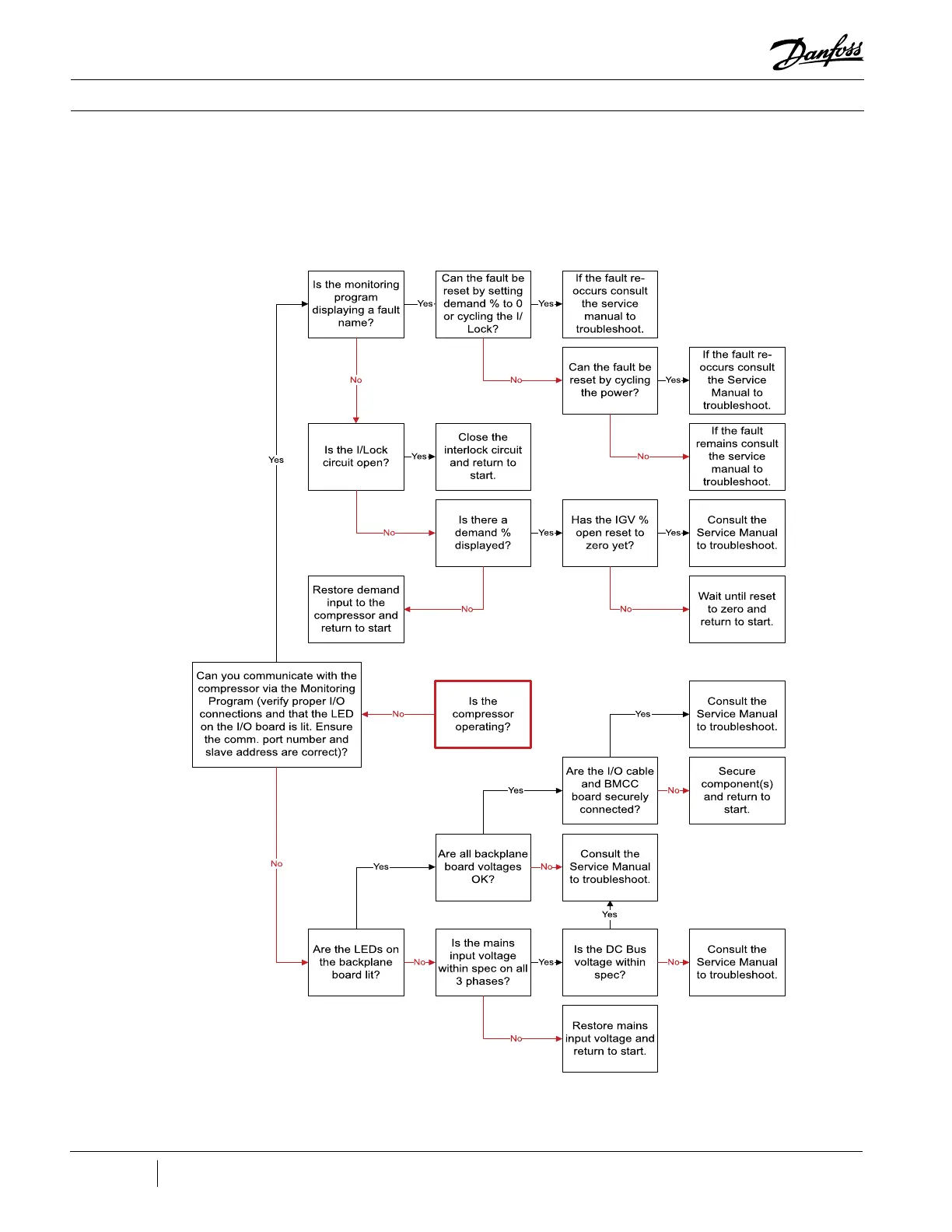

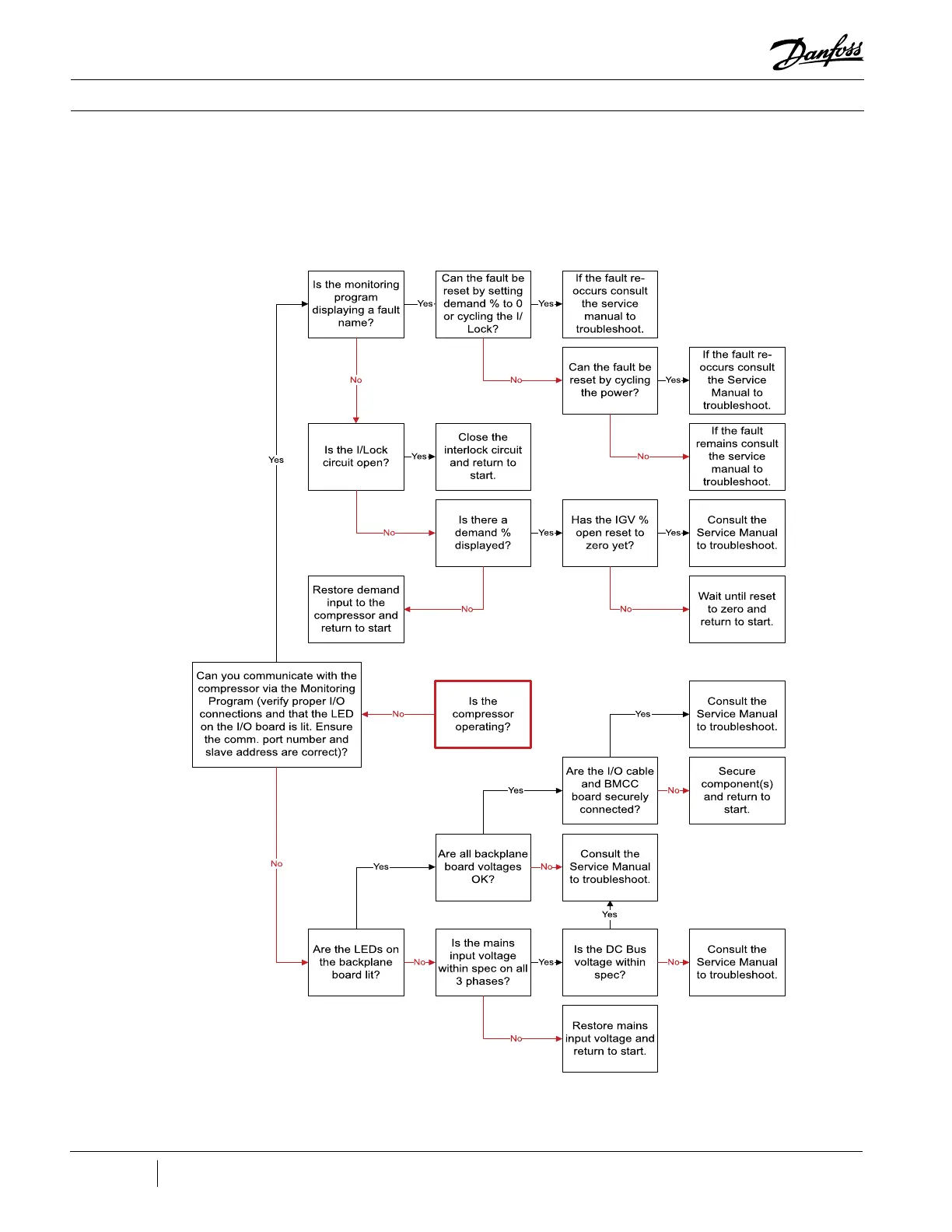

Appendix B Compressor Troubleshooting Flowcharts

This appendix contains flowcharts for

Compressor Operation Troubleshooting (Figure

108) and Compressor Voltage Troubleshooting

(Figure 109 and Figure 110).

Figure 108 - Compressor

Operation Troubleshooting

Flowchart

Loading...

Loading...