Do you have a question about the Datalogic Matrix 300 and is the answer not in the manual?

Connect the Matrix 300 reader to the system for initial setup.

Guide on physically installing and orienting the reader for optimal performance.

Use laser pointers and autofocus for precise reader positioning and setup.

Configure reader settings using the X-PRESS™ interface for optimal code reading.

Software installation for reader configuration and monitoring.

Step-by-step guide for configuring liquid lens models using the setup wizard.

Step-by-step guide for configuring fixed lens models using the setup wizard.

Verify reading performance by testing the reader with application-specific codes.

Explore advanced configuration options beyond the rapid setup process.

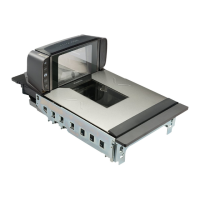

Overview of the Matrix 300™ imager, its capabilities, and target industries.

Explanation of the reader's LEDs, keypad, and their functions for operation.

Details on the ID-NET™ interface for high-speed reader interconnection and network configurations.

Procedures for backing up and restoring reader configurations using VisiSet™.

Understanding the X-PRESS™ interface for intuitive reader setup and maintenance.

Details on reader models, illuminators, and available accessories for system expansion.

Illustrates various use cases and applications where the Matrix 300™ excels.

List of items included in the Matrix 300™ package for installation.

Overall dimensions and mounting hole specifications for physical installation.

Guidance on using mounting brackets for reader installation and orientation.

Detailed pinouts and connection methods for CBX boxes and various interfaces.

Information on power requirements for standard and PoE models.

Details on RS232, RS485/422, and Ethernet interfaces for communication.

Configuration and connection of digital inputs and outputs for system integration.

Formulas and data to calculate the reader's Field of View for specific applications.

Visual representations of Field of View for different lens models and code resolutions.

Guides for understanding reading performance and using pre-configured .INI files.

Performance data and diagrams for 1D and 2D codes on specific models.

Calculations and factors affecting maximum line speed and exposure time.

Prerequisites and steps for installing the VisiSet™ configuration software.

Initializing VisiSet™ and configuring its logging, environment, and communication settings.

Setting up static IP addresses for Ethernet connectivity with VisiSet™.

Modifying reader parameters like operating mode, calibration, and communication settings.

Detailed guide on adjusting individual parameters within the VisiSet™ Parameter Setup window.

Saving and managing reader configurations to permanent memory or files.

Fine-tuning reader performance and acquisition parameters using the Calibration Tool.

Configuring multiple image acquisition settings for variable application conditions.

Enabling RTST for automatic adjustment of acquisition parameters in dynamic environments.

Optimizing frame rates by defining specific processing regions within the reader's FOV.

Configuring settings specific to Direct Part Marking (DPM) applications.

Analyzing captured images, decoded data, and performance statistics within VisiSet™.

Procedure for cleaning the reader's optical window to ensure correct operation.

Common issues and solutions for reader problems, including power and trigger signals.

Summary of electrical, optical, environmental, and physical features of the Matrix 300™.

Details on alternative cabling and connector pinouts for custom integrations.

Statement confirming compliance with relevant European Council Directives and standards.

| Operating Temperature | 0 °C to 45 °C |

|---|---|

| Resolution | 8 mils (1D codes); 10 mils (2D codes) |

| Reading Distance | 30-300 mm |

| Interface | RS-232 |

| Connectivity | Ethernet, Serial |

| Power Supply | 10 to 30 VDC |

| Dimensions | 2.5 x 1.1 x 1.7 in |

| Weight | 2.5 oz |

| Storage Temperature | -20°C to 60°C |

| Barcode Symbologies | Code 39, Code 128, UPC/EAN, Interleaved 2 of 5 |