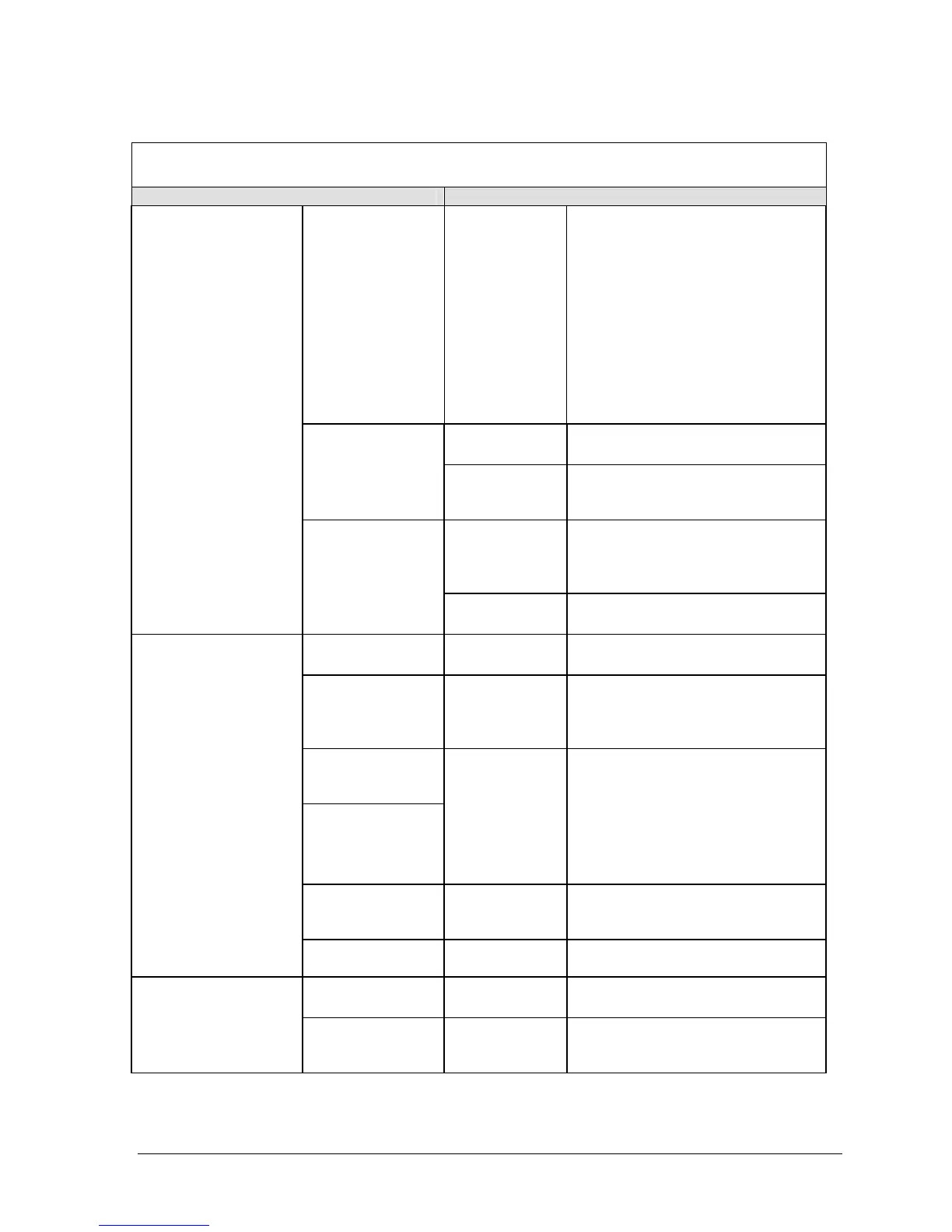

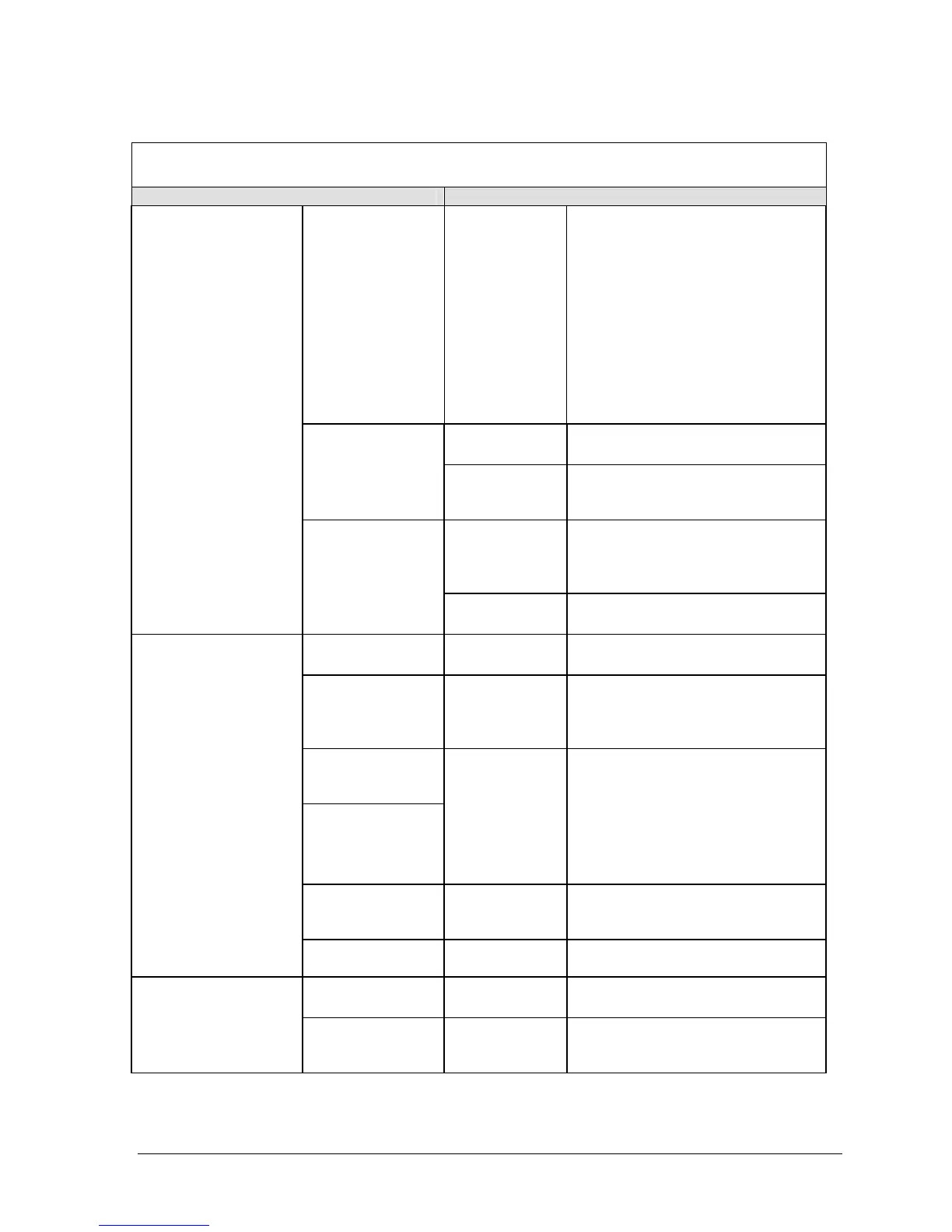

Chapter 5: Troubleshooting

Operation Manual: Evolution Series

Mechanical

PROBLEM POSSIBLE SOLUTION

Loosen the screws (big) slightly

until you get a slight movement of

the spindle in question.

Loosen or tighten one of the

setscrews until you can set the

pointer of the gauge between the

low and high deflection of the

meter.

Carefully start tightening the big

screws making sure that the

pointer of the gauge only moves

slightly.

Shaft

wobble/run out

Shaft

Refer to “Shaft wobble/run out”.

Vessels Non-Distek

vessels

Replace non-Distek vessels (Distek

vessels have a tighter inside

diameter tolerance).

Mounting

Check the installation of the

centering arm making sure that

the plastic nylon post is flush with

the arm.

Vessel

centering arm

assembly

Centering

arm

Replace if centering arm is broken

or has defects.

Paddle and

basket height

Height block

Refer to manual for “Paddle and

Basket Height Adjustment”.

Shaft collars Locking

collars

Make sure that when locking the

shaft collars the shaft does not

move (slightly push down the

shaft while locking the collars).

APPARATUS

HEIGHT

ADJUSTMENT

Vessels Non-Distek

vessels

Replace non-Distek vessels (Distek

vessels have a tighter inside

diameter tolerance).

Brake tension Tension

Adjust the tension of the brake

assembly.

Drive posts Guide posts

Clean drive post.

Use cloth dampened with alcohol

and wipe dry.

DRIVE HEAD

MOVEMENT

DIFFICLUT TO

RAISE AND LOWER

Gas Spring Gas Spring

Replace if gas spring is found

defective (pressure leakage).

Drive belts Drive belts

tension

Check for drive belts tension.

Adjust if necessary.

NOISE IN DRIVE

ASSEMBLY

Drive motor Brushes

Check the drive motor’s

conductive brushes for wear.

Replace the brushes if necessary.

Loading...

Loading...