6-7

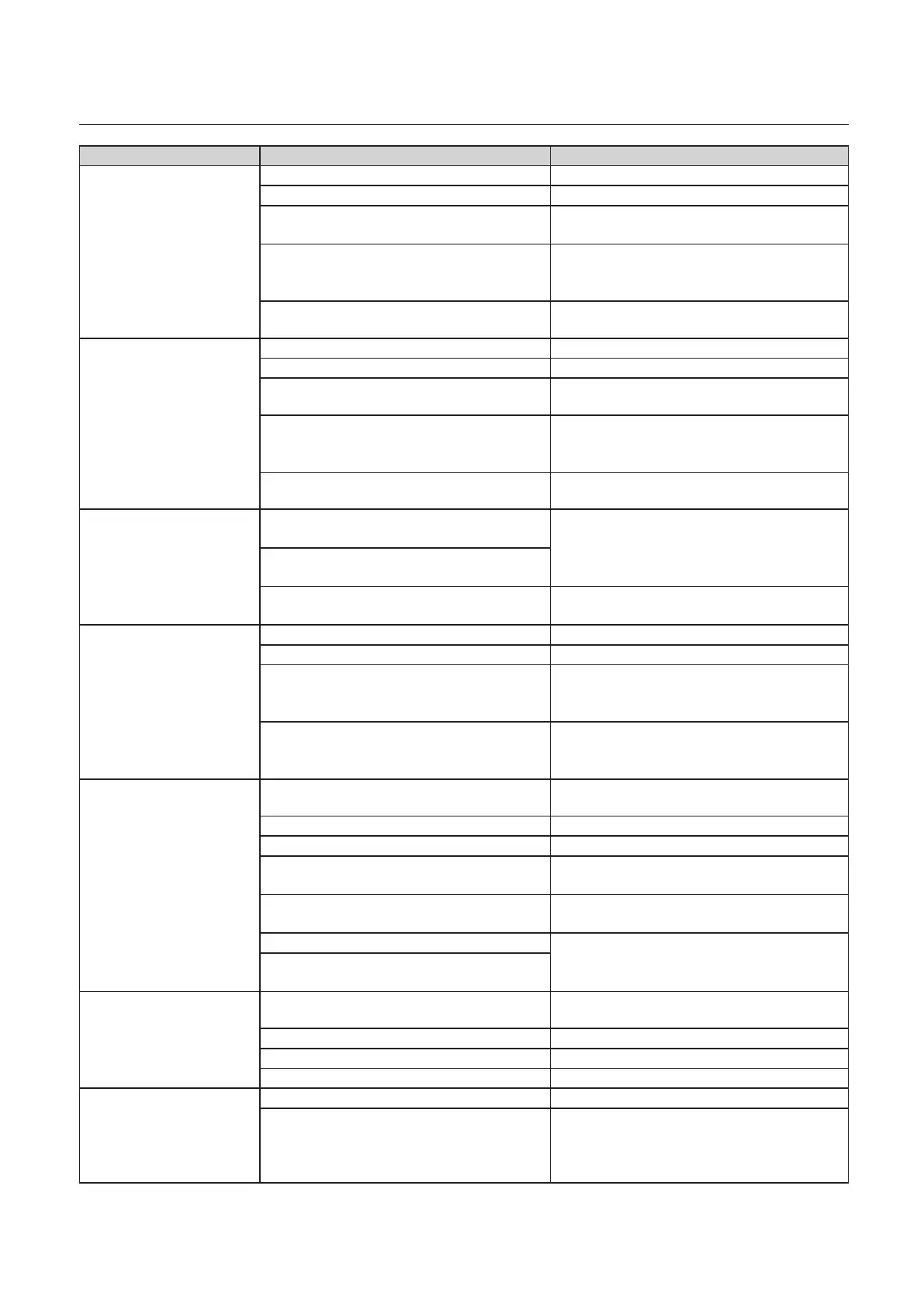

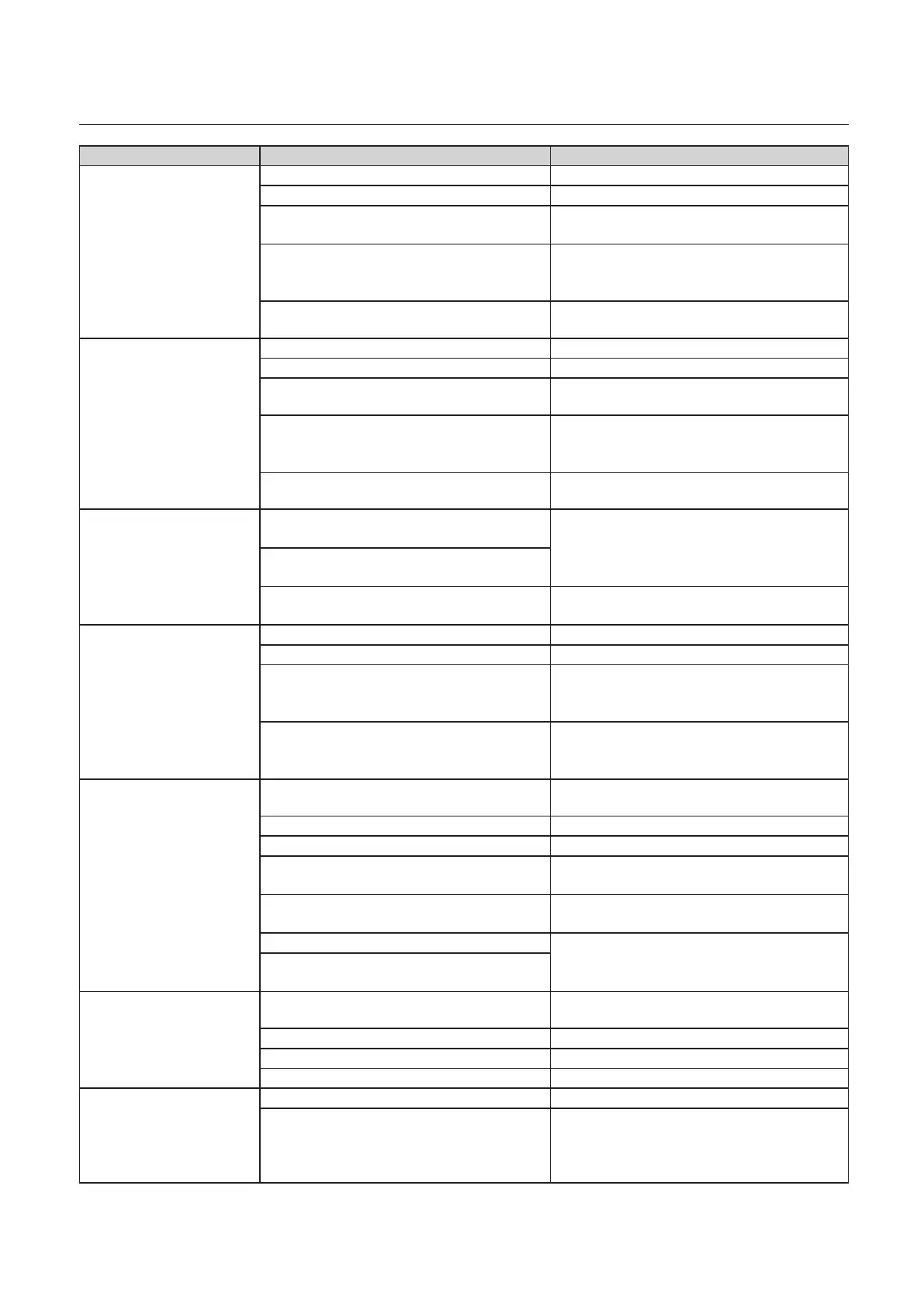

Chapter 6 Trouble Guide

Condition Cause Solution

Paper is double-feed. Paper feed pressure is too high. Decrease the paper feed pressure.

(p.2-6)

Paper separating pressure is too low. Increase the paper separating pressure.

(p.2-6)

The paper separator is stained. For the cleaning of paper separator, contact

Duplo dealer.

Paper is sticking and dicult to separate. Check that the printing ink of the paper has

dried and there is no static electricity, and

then separate the paper well.

Paper out of specications is used. Do not use paper outside the specications.

(p.1-17)

Miss-feed occurs at the

paper feed section

Paper feed pressure is too low. Increase the paper feed pressure.

(p.2-6)

Paper separating pressure is too high. Decrease the paper separating pressure.

(p.2-6)

The paper feed ring is stained. Clean with a cloth moistened with alcohol.

(p.5-1)

Paper is sticking and dicult to separate. Check that the printing ink of the paper has

dried and there is no static electricity, and

then separate the paper well.

(p.1-18)

Paper out of specications is used. Do not use paper outside the specications.

(p.1-17)

Folding misalignment

along the vertical length

of the paper occurs.

Processing speed was changed midway

through operation.

Adjust the folding stopper positions of

folding plates 1 and 2.

(p.3-3)

Paper type (quality, thickness) was

changed midway through operation.

The folding plate was removed while the

stopper xed mode was ON.

Press down cancel key and clear key at the

same time.

Folding misalignment

along the sides of the

paper occurs.

Too many sheets of paper are stacked. Reduce the paper amount.

The paper feed guides are not set properly. Set the paper feed guides properly.

(p.2-3)

The xing screws of the paper feed guides

got loose and the paper feed guide slipped

out of position.

Tighten the xing screws of the paper feed

guides

. (p.2-3)

Paper is not cut properly. Correct the folding misalignment along the

sides of the paper using the skew correction

knob.

(p.3-2)

Continuous-feeding

occurs with small paper.

Paper out of specications is used. Do not use paper outside the specications.

(p.1-17)

Paper feed pressure is too high. Decrease the paper feed pressure.

(p.2-6)

The separating pressure is too low. Increase the separating pressure.

(p.2-6)

The paper feed guides are not set properly. Set the paper feed guide according to the

paper.

(p.2-3)

Paper is not properly aligned. Align the paper well before stacking on the

paper feed tray.

(p.1-18)

Thin imsy paper is used. Lower the processing speed.

(p.3-24)

Paper size with limitations in processing

speed is used.

Single-folded thick paper

jams at the folding rollers.

Paper out of specications is used. Do not use paper outside the specications.

(p.1-17)

Paper feed pressure is too high. Decrease the paper feed pressure.

(p.2-6)

The processing speed is too slow. Increase the processing speed.

(p.3-24)

Paper is not separated well. Separate the paper well.

(p.1-18)

When large paper is

stacked on the paper feed

tray, the tray does not rise

even when the start key is

pressed.

Too many sheets of paper are stacked. Reduce the paper amount.

Heavy paper is used. Increase the paper feed pressure.

(p.3-24)

Loading...

Loading...